Description

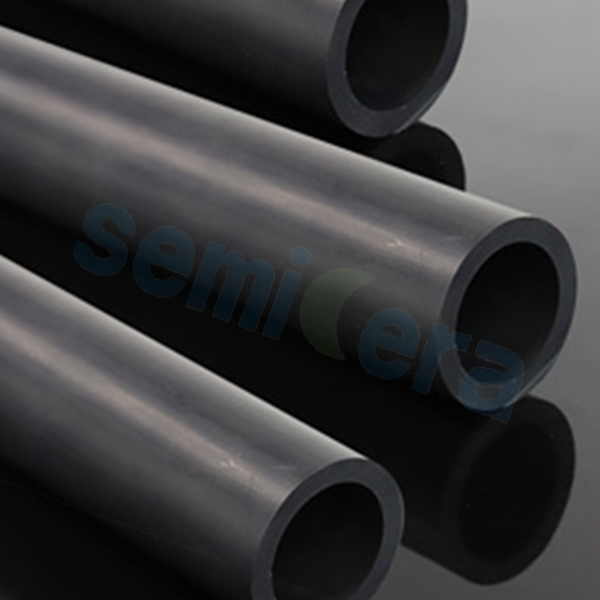

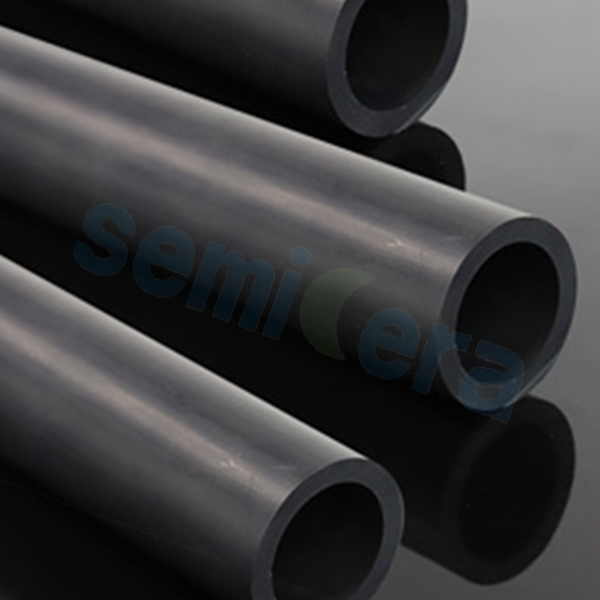

Silicon carbide grinding drum adopts isostatic pressing molding process, density 3.09g/cm3, maximum φ950mm, Vickers hardness 2550HV.

Application of Silicon carbide ceramic grinding barrel in metallurgy and chemical industry From the 1970s to the early 1990s, silicon carbide ceramic grinding barrel has a high resistance to molten iron, slag, alkali metal corrosion resistance, and has high thermal conductivity and property. 65 large blast furnaces in the world use silicon nitride and silicon carbide as furnace materials, so that aluminum, copper, zinc smelting time extended to 2096-40%. Various SIC materials are also used as linings or crucible. In the chemical and metallurgical industries, ceramic heat exchangers are commonly used to preheat various gases or liquids to make full use of the heat in the exhaust gas of various heating furnaces.

![]()

![]()

Silicon carbide grinding barrel advantage

(1) High mechanical strength, as good as

High mechanical strength can effectively prevent material deformation, which is very important. Silicon carbide has higher mechanical strength than corundum. For example, the compressive strength of silicon carbide is 224MPa, while that of corundum is only 75.7MPa. The bending strength of silicon carbide is 15.5MPa, and that of corundum is 8.72MPa.

(2) High hardness and wear resistance

Silicon carbide hardness is quite high, according to the Mohs notch hardness between 9.2 ~ 9.6, second only to diamond and boron carbide, higher than corundum, so in the common grinding and shaking among the best. Compared with metal steel material, it is not only high hardness, but also in the non-lubricating state of friction coefficient is small, relatively small friction, surface roughness is small, wear resistance is good. In addition to the external material has a strong impact resistance, improve the surface bearing capacity.

(3) Corrosion resistance

Silicon carbide because of its melting point (decomposition temperature), chemical inertia and thermal shock resistance is high, can be used for a variety of silicon carbide ceramic products, such as ceramic products furnace grinding tools, ceiling plate and sagger, zinc smelting industrial vertical cylinder distillation furnace with silicon carbide brick, aluminum electrolytic cell lining, crucible, small furnace material.

Corrosion resistance application

1, sliding parts (mechanical seal, chemical pump bearing, shaft)

2, crusher accessories (classifier, air mill, sand mill)

3.Semiconductor manufacturing equipment parts (XY platform, MOCVD tray, focusing ring, wafer chuck)

4. Parts of molding machine (parts of camera lens molding machine)

5 heat resistant parts (burner nozzle, high temperature testing machine parts, molten metal crucible)

6. Wear-resistant parts (sand blasting machine nozzle, shot blasting machine polishing machine blade, buried pipeline protection plate, fishing tackle guide ring)

Company

Wei Tai Energy Technology Co., Ltd.(Miami Advanced Material Technology Co., Ltd) is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

Our main products including: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat(Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, as well as the CVD SiC coating and TaC coating. The products mainly used in the semiconductor and photovoltaic industries, such as equipment for crystal growth, epitaxy, etching, packaging, coating and diffusion furnaces,etc.

Our company has the complete production equipment such as molding, sintering, processing , coating equipment, etc., which can complete all the necessary links of product production and have higher controllability of product quality; The optimal production plan can be selected according to the needs of the product, resulting in lower cost and providing customers with more competitive products; We can flexibly and efficiently schedule production based on order delivery requirements and in conjunction with online order management systems, providing customers with faster and more guaranteed delivery time.

FAQ

Q: Are you trading company or manufacturer?

A:We are an more than 10 vears factory with iso9001 certificacted

Q:How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock,or 10-15 days if the goods are not in stock, it is according to your quantity.

Q: How can Iget the sample to check your quality?

A: After price confirmation, you can require for samples to check our product's quality. If you just need a blank sample to check the design and quality,we will provide you sample for free as long as you afford the express freight.

Q:What is your terms of payment?

A: We accept payment by Western union,Pavpal,Alibaba,T/TL/Cetc..for bulk order,we do 30% deposit balance before shipment.

if you have another question,pls feel free to contact us as below

-

Discountable price Chinese Supplier Sisic, Rbsi...

-

Long Service Life SiC Coated Graphite Carrier F...

-

Big discounting Ceramics silicon carbide roller...

-

OEM/ODM China Diamond Silicon Carbide Black Cor...

-

Factory Price For Industrial Customized Black S...

-

Hot New Products Factory Price Custom Industria...