MEMS Processing - Bonding: Application and Performance in the Semiconductor Industry, Semicera Customized Service

In the microelectronics and semiconductor industries, MEMS (micro-electromechanical systems) technology has become one of the core technologies that drive innovation and high-performance equipment. With the advancement of science and technology, MEMS technology has been widely used in sensors, actuators, optical devices, medical equipment, automotive electronics and other fields, and has gradually become an indispensable part of modern technology. In these fields, the bonding process (Bonding), as a key step in MEMS processing, plays a vital role in the performance and reliability of the device.

Bonding is a technology that firmly combines two or more materials by physical or chemical means. Usually, different material layers need to be connected by bonding in MEMS devices to achieve structural integrity and functional realization. In the manufacturing process of MEMS devices, bonding is not only a connection process, but also directly affects the thermal stability, mechanical strength, electrical performance and other aspects of the device.

In high-precision MEMS processing, bonding technology needs to ensure the close bonding between materials while avoiding any defects that affect the performance of the device. Therefore, precise control of the bonding process and high-quality bonding materials are key factors to ensure that the final product meets industry standards.

MEMS bonding applications in the semiconductor industry

In the semiconductor industry, MEMS technology is widely used in the production of micro devices such as sensors, accelerometers, pressure sensors, and gyroscopes. With the increasing demand for miniaturized, integrated, and intelligent products, the accuracy and performance requirements of MEMS devices are also increasing. In these applications, bonding technology is used to connect different materials such as silicon wafers, glass, metals, and polymers to achieve efficient and stable functions.

1. Pressure sensors and accelerometers

In the fields of automobiles, aerospace, consumer electronics, etc., MEMS pressure sensors and accelerometers are widely used in measurement and control systems. The bonding process is used to connect silicon chips and sensor elements to ensure high sensitivity and accuracy. These sensors must be able to withstand extreme environmental conditions, and high-quality bonding processes can effectively prevent materials from detaching or malfunctioning due to temperature changes.

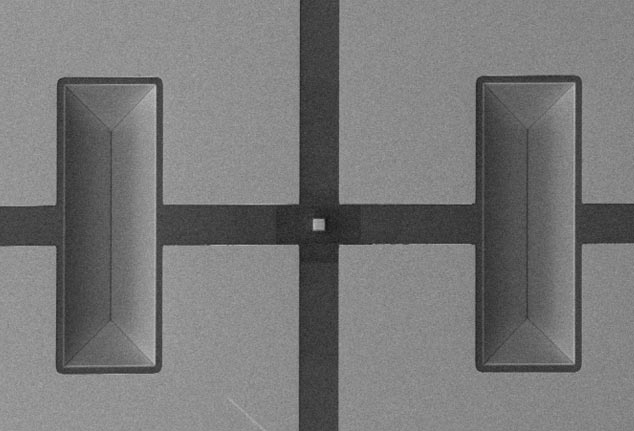

2. Micro-optical devices and MEMS optical switches

In the field of optical communications and laser devices, MEMS optical devices and optical switches play an important role. Bonding technology is used to achieve precise connection between silicon-based MEMS devices and materials such as optical fibers and mirrors to ensure the efficiency and stability of optical signal transmission. Especially in applications with high frequency, wide bandwidth and long-distance transmission, high-performance bonding technology is crucial.

3. MEMS gyroscopes and inertial sensors

MEMS gyroscopes and inertial sensors are widely used for precise navigation and positioning in high-end industries such as autonomous driving, robotics, and aerospace. High-precision bonding processes can ensure the reliability of devices and avoid performance degradation or failure during long-term operation or high-frequency operation.

Key performance requirements of bonding technology in MEMS processing

In MEMS processing, the quality of the bonding process directly determines the performance, life and stability of the device. In order to ensure that MEMS devices can work reliably for a long time in various application scenarios, bonding technology must have the following key performance:

1. High thermal stability

Many application environments in the semiconductor industry have high temperature conditions, especially in the fields of automobiles, aerospace, etc. The thermal stability of the bonding material is crucial and can withstand temperature changes without degradation or failure.

2. High wear resistance

MEMS devices usually involve micro-mechanical structures, and long-term friction and movement may cause wear of the connection parts. The bonding material needs to have excellent wear resistance to ensure the stability and efficiency of the device in long-term use.

3. High purity

The semiconductor industry has very strict requirements on material purity. Any tiny contaminant may cause device failure or performance degradation. Therefore, the materials used in the bonding process must have extremely high purity to ensure that the device is not affected by external contamination during operation.

4. Precise bonding accuracy

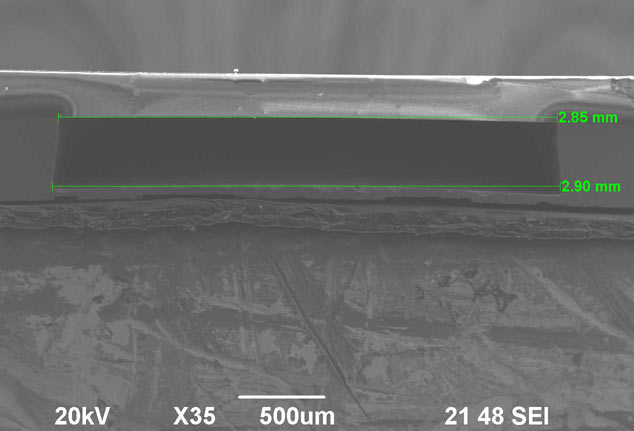

MEMS devices often require micron-level or even nanometer-level processing accuracy. The bonding process must ensure the precise docking of each layer of material to ensure that the function and performance of the device are not affected.

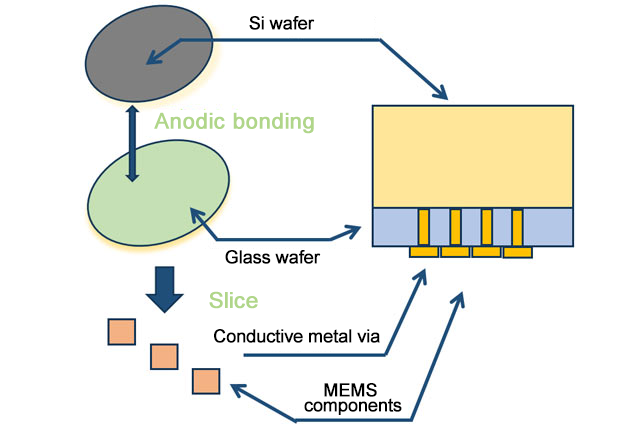

Anodic bonding

Anodic bonding:

● Applicable to bonding between silicon wafers and glass, metal and glass, semiconductor and alloy, and semiconductor and glass

Eutectoid bonding:

● Applicable to materials such as PbSn, AuSn, CuSn, and AuSi

Glue bonding:

● Use special bonding glue, suitable for special bonding glues such as AZ4620 and SU8

● Applicable to 4-inch and 6-inch

Semicera Custom Bonding Service

As an industry-leading provider of MEMS processing solutions, Semicera is committed to providing customers with high-precision, high-stability customized bonding services. Our bonding technology can be widely used in the connection of different materials, including silicon, glass, metal, ceramics, etc., providing innovative solutions for high-end applications in the semiconductor and MEMS fields.

Semicera has advanced production equipment and technical teams, and can provide customized bonding solutions according to the specific needs of customers. Whether it is reliable connection under high temperature and high pressure environment, or precise micro-device bonding, Semicera can meet various complex process requirements to ensure that each product can meet the highest quality standards.

Our custom bonding service is not limited to conventional bonding processes, but also includes metal bonding, thermal compression bonding, adhesive bonding and other processes, which can provide professional technical support for different materials, structures and application requirements. In addition, Semicera can also provide customers with full-service from prototype development to mass production to ensure that every technical requirement of customers can be accurately realized.