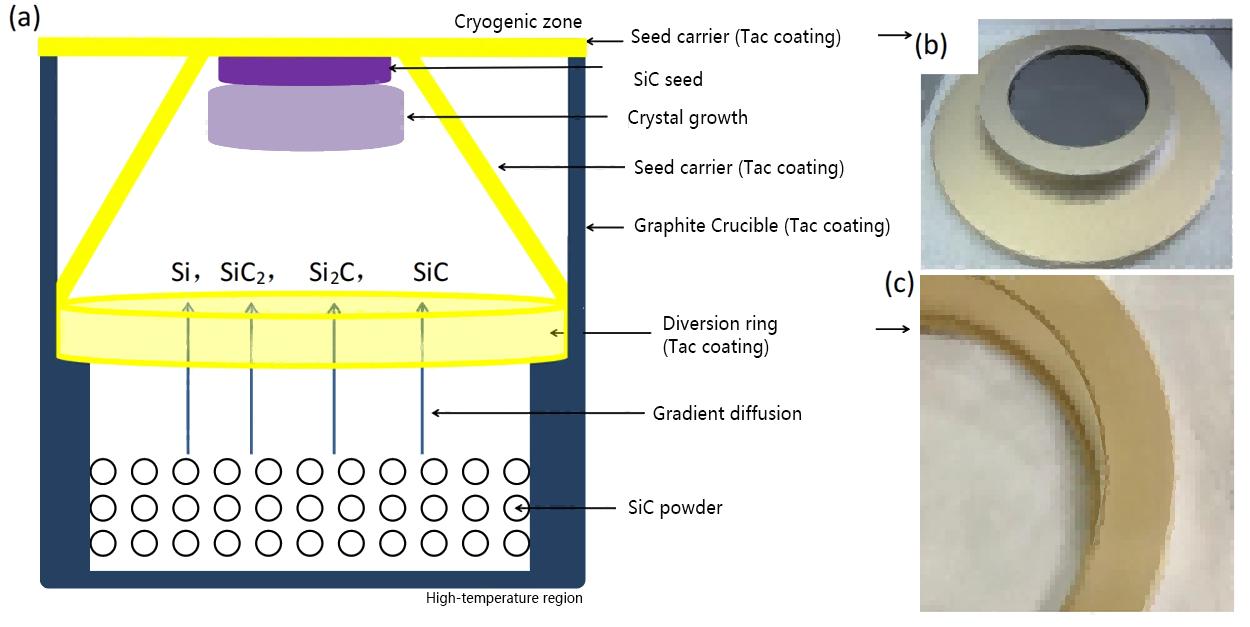

Semicera provides specialized tantalum carbide (TaC) coatings for various components and carriers. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

The working principle of tantalum carbide planetary disc is similar to that of planetary gear transmission, in which the planetary disc acts as an intermediate driving element and realizes power transmission and motion control by meshing with the inner and outer gears. The planetary disc usually has multiple tooth grooves that mesh with the inner and outer gears to achieve smooth transmission and high torque output.

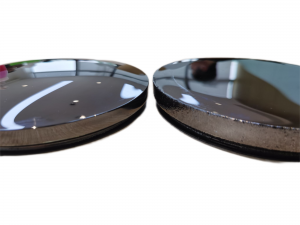

with and without TaC

After using TaC (right)

The characteristics of tantalum carbide planetary disc are as follows:

1. Wear resistance: Tantalum carbide material has extremely high hardness and wear resistance, can maintain good durability under high load and high-speed movement conditions, and reduce wear and friction loss.

2. High temperature stability: Tantalum carbide has excellent high temperature stability and can run for a long time in high temperature environment without damage, which is suitable for high temperature processes and applications.

3. Low friction coefficient: The surface of tantalum carbide has a low friction coefficient, which reduces energy loss and heat generation during transmission and improves transmission efficiency.

4. High precision and stability: Tantalum carbide planetary discs are manufactured with fine craftsmanship, high precision and stability, and can achieve precise transmission and position control.

Moreover, Semicera's TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: