Introduction to CVD TaC Coating:

CVD TaC Coating is a technology that uses chemical vapor deposition to deposit tantalum carbide (TaC) coating on the surface of a substrate. Tantalum carbide is a high-performance ceramic material with excellent mechanical and chemical properties. The CVD process generates a uniform TaC film on the surface of the substrate through gas reaction.

Main features:

Excellent hardness and wear resistance: Tantalum carbide has extremely high hardness, and CVD TaC Coating can significantly improve the wear resistance of the substrate. This makes the coating ideal for applications in high-wear environments, such as cutting tools and molds.

High Temperature Stability: TaC coatings protect critical furnace and reactor components at temperatures up to 2200°C, demonstrating good stability. It maintains chemical and mechanical stability under extreme temperature conditions, making it suitable for high-temperature processing and applications in high-temperature environments.

Excellent chemical stability: Tantalum carbide has strong corrosion resistance to most acids and alkalis, and CVD TaC Coating can effectively prevent damage to the substrate in corrosive environments.

High melting point: Tantalum carbide has a high melting point (approximately 3880°C), allowing CVD TaC Coating to be used in extreme high temperature conditions without melting or degrading.

Excellent thermal conductivity: TaC coating has high thermal conductivity, which helps to effectively dissipate heat in high-temperature processes and prevent local overheating.

Potential applications:

• Gallium Nitride (GaN) and Silicon Carbide epitaxial CVD reactor components including wafer carriers, satellite dishes, showerheads, ceilings, and susceptors

• Silicon carbide, gallium nitride and aluminum nitride (AlN) crystal growth components including crucibles, seed holders, guide rings and filters

• Industrial components including resistance heating elements, injection nozzles, masking rings and brazing jigs

Application features:

• Temperature stable above 2000°C, allowing operation at extreme temperatures

•Resistant to hydrogen (Hz), ammonia (NH3), monosilane (SiH4) and silicon (Si), providing protection in harsh chemical environments

• Its thermal shock resistance enables faster operating cycles

• Graphite has strong adhesion, ensuring a long service life and no coating delamination.

• Ultra-high purity to eliminate unnecessary impurities or contaminants

• Conformal coating coverage to tight dimensional tolerances

Technical specifications:

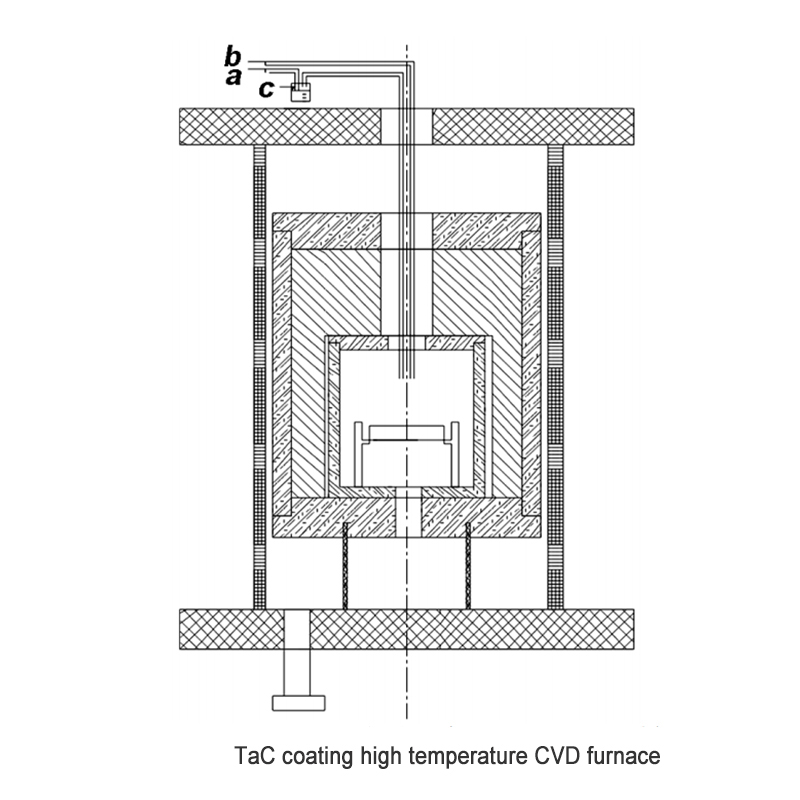

Preparation of dense tantalum carbide coatings by CVD:

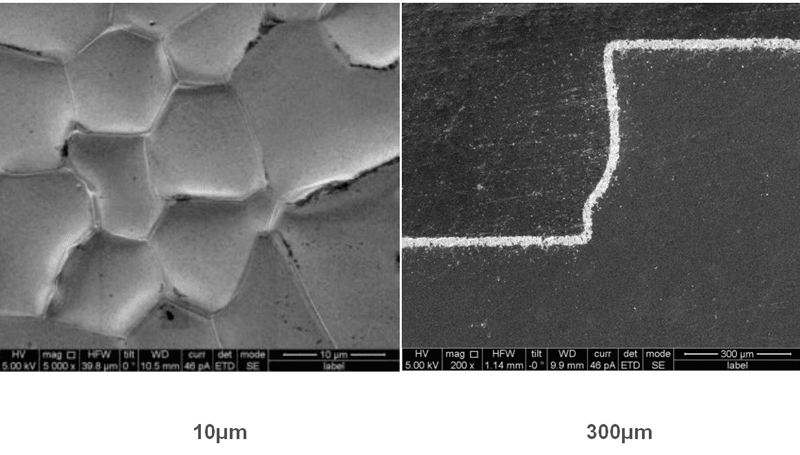

TAC coating with high crystallinity and excellent uniformity:

CVD TAC COATING Technical Parameters_Semicera:

| Physical properties of TaC coating | |

| Density | 14.3 (g/cm³) |

| Bulk Concentration | 8 x 1015/cm |

| Specific emissivity | 0.3 |

| Thermal expansion coefficient | 6.3 10-6/K |

| Hardness(HK) | 2000 HK |

| Bulk Resistivity | 4.5 ohm-cm |

| Resistance | 1x10-5 Ohm*cm |

| Thermal stability | <2500℃ |

| Mobility | 237 cm2/Vs |

| Graphite size changes | -10~-20um |

| Coating thickness | ≥20um typical value (35um+10um) |

The above are typical values.