We’re commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Special Price for High Wear Resistance Sisic Tube Reaction Sintered Silicon Carbide Pipe Customized Connetion Tube, By means of our hard get the job done, we have usually been to the forefront of clean technology products innovation. We’ve been a eco-friendly partner you can rely on. Get in touch with us today for more details!

We’re commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for China Refractory Ceramics and Kiln Furniture, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you will need more information, make sure you feel free to contact us by E-mail or telephone. We’ve been sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

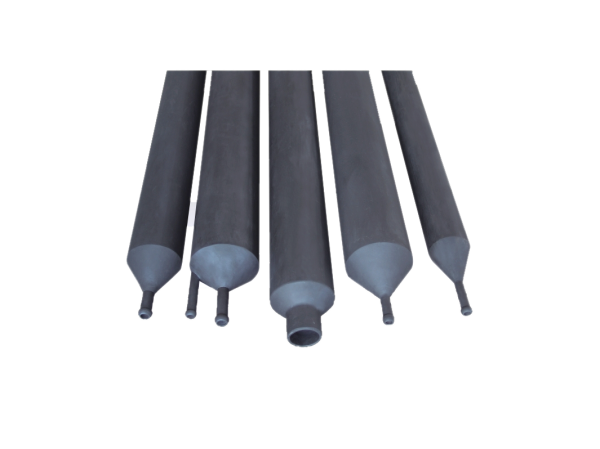

We can provide stable and reliable silicon carbide crystal boats, silicon carbide paddles, silicon carbide furnace tubes for the 4 inch to 6 inch semiconductor wafer industry. The purity can reach 99.9% without polluting the wafer.

Silicon carbide furnace tube is mainly used for: 4-6 inch silicon wafer LTO= silica, SIPOS= oxy-polysilicon, SI3N4= silicon nitride, PSG= phosphosilicon glass, POLY= polysilicon film growth. It is the raw material gas (or liquid source gasification) activated by thermal energy to generate a solid film on the surface of the substrate. Low pressure chemical vapor deposition is carried out at low pressure, due to the low pressure, the average free path of gas molecules is large, so that the uniformity of the grown film is good, and the substrate can be vertically placed and the amount of loading is large, especially suitable for large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and optical fiber and other industries of industrial production special equipment.

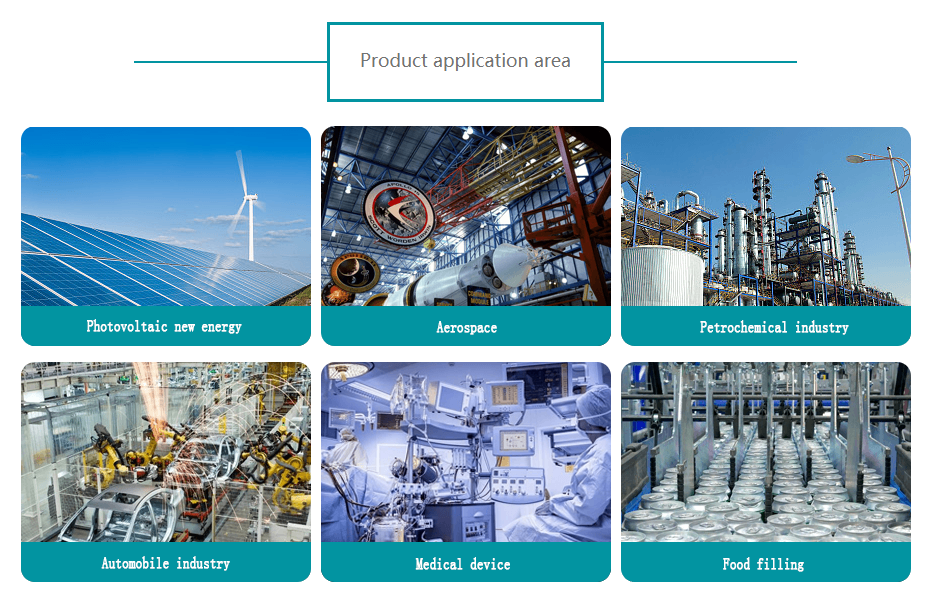

Semicera Energy Technology Co., Ltd is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process, grouting molding process and vacuum extrusion molding process. Our company uses 6 silicon carbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can also provide you with silicon carbide ceramic sintered products, but also can provide silicon carbide ceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.

We’re commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Special Price for High Wear Resistance Sisic Tube Reaction Sintered Silicon Carbide Pipe Customized Connetion Tube, By means of our hard get the job done, we have usually been to the forefront of clean technology products innovation. We’ve been a eco-friendly partner you can rely on. Get in touch with us today for more details!

Special Price for China Refractory Ceramics and Kiln Furniture, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you will need more information, make sure you feel free to contact us by E-mail or telephone. We’ve been sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

-

China Supplier Transparent Quartz Glass Boats f...

-

High reputation High Performance Pressureless S...

-

China New Design 1500c ED Type Sic Heater Silic...

-

Factory Directly supply Melting Metal Graphite ...

-

Hot Selling for Silicon Carbide Graphite Crucib...

-

2019 New Style Factory Price Custom Industrial ...