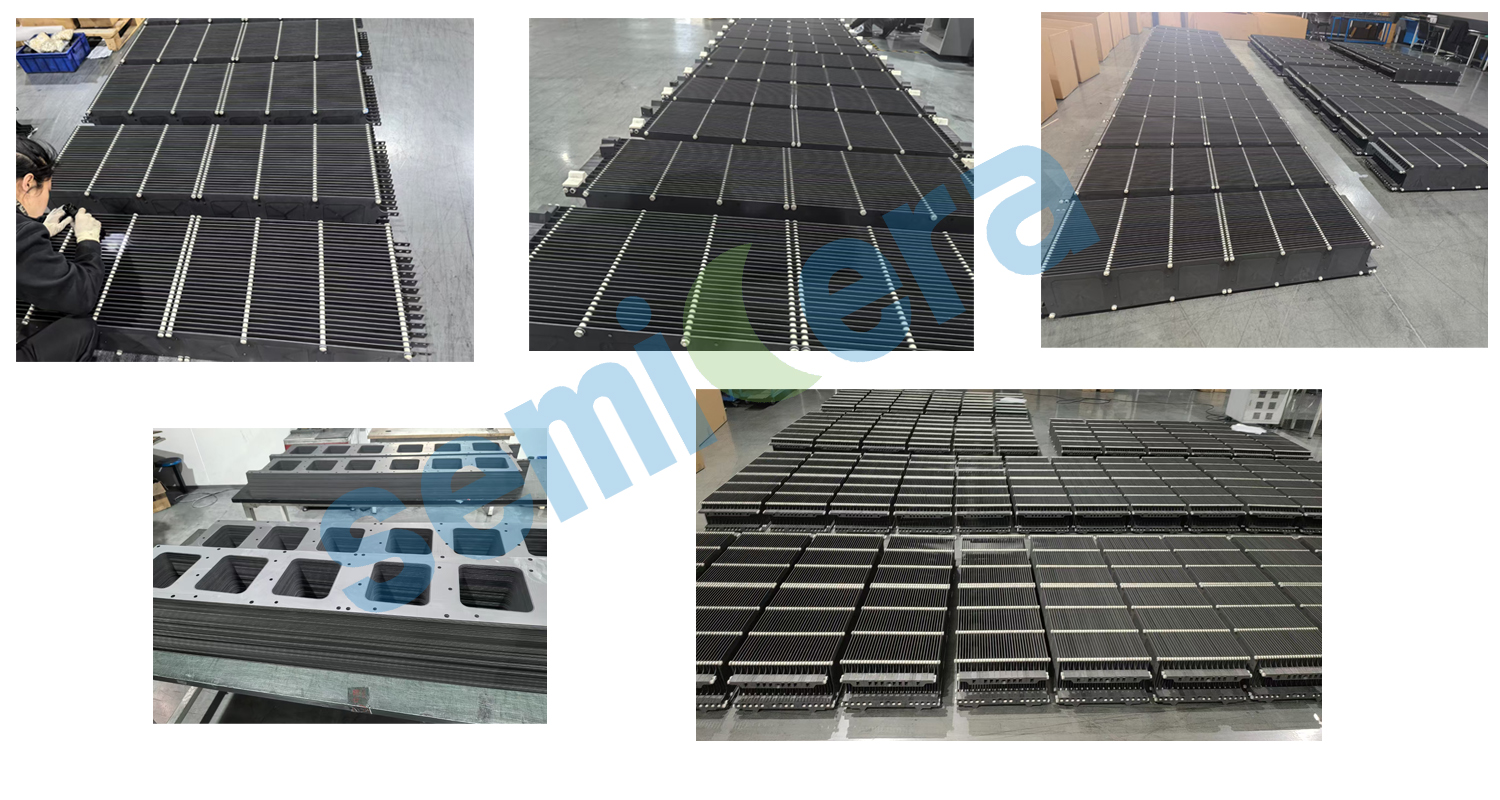

Solar Graphite Boat for PECVD Solar Cell Production

Maximize Efficiency in Solar Cell Manufacturing with High-Performance Graphite Boats

Semicera Solar Graphite Boats are specially designed to serve as essential carriers for silicon wafers during the Plasma-Enhanced Chemical Vapor Deposition (PECVD) process in solar cell production. With advanced features like high-temperature resistance, excellent electrical conductivity, and chemical stability, our graphite boats play a pivotal role in optimizing production efficiency and ensuring the highest quality in solar cell manufacturing.

Key Features

1. Precision Engineered for Solar Cell Applications

Our graphite boats are meticulously crafted using high-purity graphite materials with low impurity content, ensuring uniform temperature distribution and excellent heat retention during the PECVD process. This precise engineering ensures the protection and optimal performance of silicon wafers.

2. Enhanced Durability and Corrosion Resistance

We utilize the latest 99.9% ceramic components for assembly, providing unmatched corrosion resistance and burst-proof properties. This makes our boats highly reliable for long-term use in high-temperature environments without compromising their integrity.

3. Color Lens-Free Technology

Through the adoption of "color lenses" elimination technology, our boats prevent any unwanted coloration during extended high-temperature processes. This technology ensures a clearer, more consistent result in every batch of solar cells, reducing defects and improving yield.

4. High Thermal Conductivity

With graphite's natural high thermal conductivity, our boats facilitate rapid heat distribution across the silicon wafer surface. This ensures precise temperature control and faster processing, which is crucial for achieving optimal results in solar cell manufacturing.

5. Customizable Sizes for Different Production Needs

Our Solar Graphite Boats come in various sizes to accommodate different wafer dimensions. Whether you're working with 156mm or 125mm wafers, we offer a wide range of options tailored to your production specifications.

Specifications

|

Series |

Wafer Size (mm) |

Wafer Capacity |

Part Number |

|

156 Series |

156 x 13 |

144 |

156-13 Graphite Boat |

|

|

156 x 19 |

216 |

156-19 Graphite Boat |

|

|

156 x 21 |

240 |

156-21 Graphite Boat |

|

|

156 x 23 |

308 |

156-23 Graphite Boat |

|

125 Series |

125 x 15 |

196 |

125-15 Graphite Boat |

|

|

125 x 19 |

252 |

125-19 Graphite Boat |

|

|

125 x 21 |

280 |

125-21 Graphite Boat |

Applications

1. Solar Cell Manufacturing

Graphite boats are an integral part of the PECVD process used in solar cell production. By ensuring uniform heat distribution, they help achieve high-efficiency silicon wafers, contributing to the overall performance and longevity of the solar cells.

2. Silicon Wafer Handling

Used during high-temperature treatment processes like diffusion and etching, our boats safely transport silicon wafers, ensuring they remain free of contaminants and damage, thereby enhancing the quality of solar cells produced.

3. High-Temperature Coating

During the PECVD process, these boats facilitate the deposition of silicon nitride films on the silicon wafers, significantly reducing sunlight reflection. This enhances the solar conversion efficiency of the wafers.

Advantages of Using Our Graphite Boats

1. High Temperature Resistance: Our graphite boats can withstand extreme temperatures exceeding 2000°C, making them suitable for the demanding environments of solar cell production.

2. Low Thermal Expansion: The low coefficient of thermal expansion ensures that the boats remain structurally stable, even under rapid temperature changes, preventing warping or deformation.

3. Enhanced Service Life: The combination of high-strength graphite and reinforced epoxy resin materials allows for longer service life, even under the most extreme conditions.

4. Low Heat Loss: With high thermal conductivity, our graphite boats ensure minimal heat loss during the coating process, which enhances process efficiency and reduces energy consumption.

Why Choose Semicera Solar Graphite Boats?

1. Tailored Solutions: We offer customized graphite boats designed to meet specific production requirements, ensuring the best fit for your solar cell manufacturing process.

2. Superior Material Quality: Our boats are made from imported, high-purity graphite, ensuring durability, strength, and reliability.

3. Technological Innovation: With cutting-edge color lens-free technology, precise processing methods, and advanced ceramic components, our graphite boats deliver enhanced performance and superior results.

Request a Quote

Looking to optimize your solar cell production process? Contact us today to request a quote or inquire about custom solutions for your specific needs. Our team of experts is ready to provide high-quality graphite boats tailored to your production requirements.

Conclusion

The Solar Graphite Boat is a critical component in the efficient and high-quality production of solar cells. With advanced features such as superior thermal conductivity, high-temperature resistance, and corrosion resistance, our graphite boats offer unmatched performance and durability in PECVD applications. Optimize your solar production line today with our high-performance graphite boats!

FAQs

1. What makes your graphite boats different from others?

Our boats are made from high-purity graphite and feature innovative technologies like color lens-free technology and corrosion-resistant ceramic assemblies, offering superior performance and durability.

2. Are your graphite boats customizable?

Yes, we offer a range of sizes to accommodate different wafer dimensions and production requirements, ensuring an optimal fit for your specific process.

3. How long can the graphite boats last?

With proper maintenance, our graphite boats are designed to withstand long-term use in high-temperature environments, providing extended service life.