The Soft Graphite Felt for Insulating by Semicera is designed to provide exceptional thermal insulation for high-temperature applications. This advanced material showcases the unique properties of isostatic graphite, offering superior flexibility and durability. Ideal for use in various industries, including aerospace, electronics, and metallurgy, this felt effectively prevents heat loss, ensuring energy efficiency and enhanced performance.

Crafted from high-quality porous graphite, the Soft Graphite Felt maintains its structural integrity even in extreme environments. It provides a lightweight solution for insulation while delivering high levels of thermal resistance. In addition, the product’s composition allows for easy integration with other materials, such as graphite foil and C/C composites, making it a versatile choice for various applications.

With Semicera’s commitment to quality, this insulating felt combines the benefits of rigid felt and soft felt, ensuring a perfect balance between resilience and adaptability. The Soft Graphite Felt for Insulating is an essential component for industries looking to optimize thermal management and enhance the longevity of their systems. Trust Semicera for reliable insulation solutions that meet your high-performance requirements.

Product details

|

Product name |

Graphite Felt |

|

Chemical Composition |

Carbon fiber |

|

Bulk density |

0.12-0.14g/cm3 |

|

Carbon content |

>=99% |

|

Tensile Strength |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0.08~0.14W/mk |

|

Ash |

<=0.005% |

|

Crushing stress |

8-10N/cm |

|

Thickness |

1-10mm |

|

Processing temperature |

2500(℃) |

Currently available in four specifications, each available in rolls, parts and pre-rolled felt tubes:

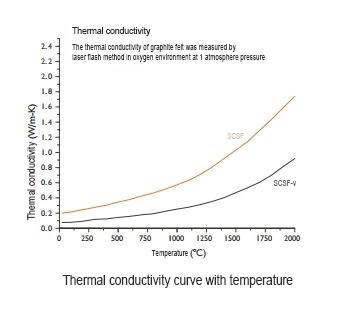

SCSF: High purity graphite felt, better thermal conductivity, heat treatment temperature of more than 1900℃

SCSF-p: Ultra-high purity SCSF-B graphite felt

SCSF-v: High purity graphite felt, heat treatment temperature of more than 2650℃, low thermal conductivity

SCSF-v-p: Ultra-high purity SCSF-D graphite felt

Properties :

-Outstanding thermal stability

-High mechanical strength

-Good electrical and thermal conductivity

-Excellent resistance to thermal shock and corrosion

-High material purity

-High electriccal load capacity

-Uniform temperature profile

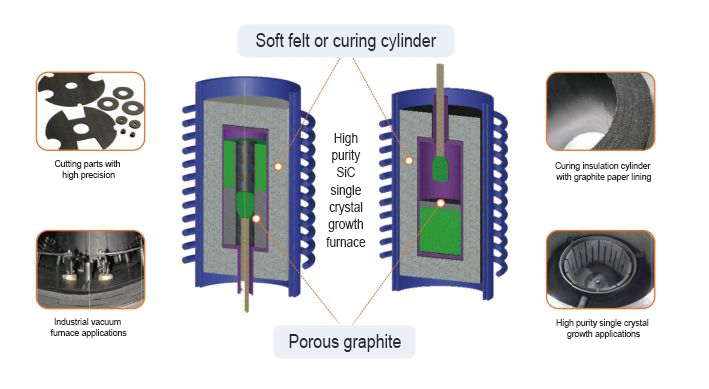

Fields of applications:

-Vacuum furnaces

-Inert gas furnaces

-Heat treatment

(hardening, carbonization, brazing, etc.)

-Carbon fiber production

-Hard metal production

-Sintering applications

-Technical ceramic production

-CVD/PVD coasting