Silicon single crystal pulling fixtures in the photovoltaic industry play a key role in solar cell manufacturing. By firmly clamping and accurately controlling the stretching and solidification process of silicon single crystal rods, fixtures help achieve high-quality and high-efficiency silicon single crystal production. The design and performance of the fixture directly affect the performance and quality of solar cells, so in the photovoltaic industry, research and development and innovation are constantly being carried out to improve the accuracy, stability and efficiency of the fixture.

Introduction:

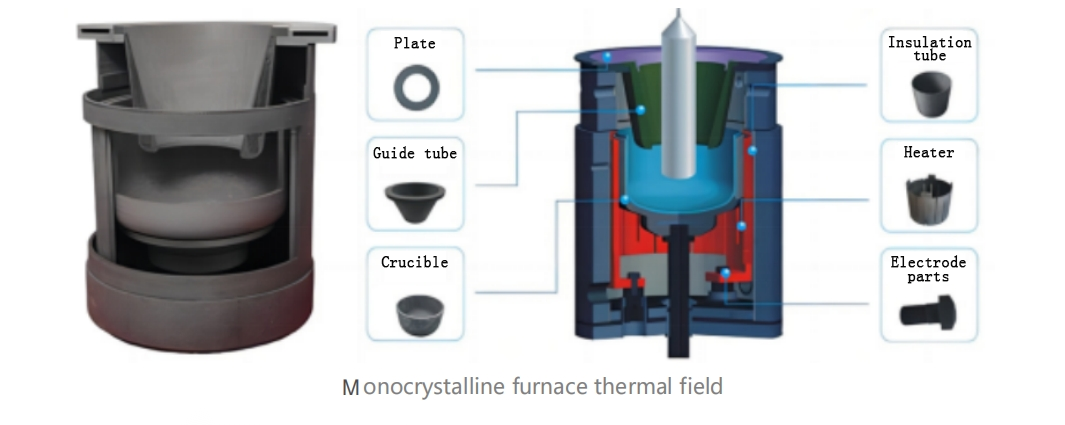

1. Fixture design: Silicon single crystal pulling fixtures in the photovoltaic industry are usually precisely designed and machined to ensure a secure grip and accurate positioning of the silicon single crystal rod. The fixture is usually made of metal materials (such as stainless steel) with high strength and rigidity to withstand high tensile forces and temperatures.

2. Clamping mechanism: The fixture clamps the silicon single crystal rod through a certain mechanical structure or clamping device. Usually, the design of the fixture takes into account the diameter and shape of the silicon single crystal rod to ensure stable clamping and prevent the silicon single crystal rod from sliding or twisting during the stretching process.

3. Temperature control: Silicon single crystal pulling fixtures in the photovoltaic industry usually have temperature control functions to ensure that the appropriate temperature conditions are maintained during the stretching and solidification process. Temperature control can be achieved through a heating or cooling system on the fixture itself, or a temperature control system integrated with the stretching equipment.

4. Precise positioning and alignment: Silicon single crystal pulling fixtures in the photovoltaic industry need to provide accurate positioning and alignment functions to ensure that the silicon single crystal rod maintains the correct direction and position during the stretching and solidification process. Accurate positioning and alignment help to obtain consistent silicon single crystal size and crystal orientation.

5. Heat resistance and corrosion resistance: Due to the high temperature and chemical reactions involved in the stretching and solidification process, the silicon single crystal pulling fixtures in the photovoltaic industry need to have good heat resistance and corrosion resistance. This helps ensure the stability and long-term reliability of the fixture.