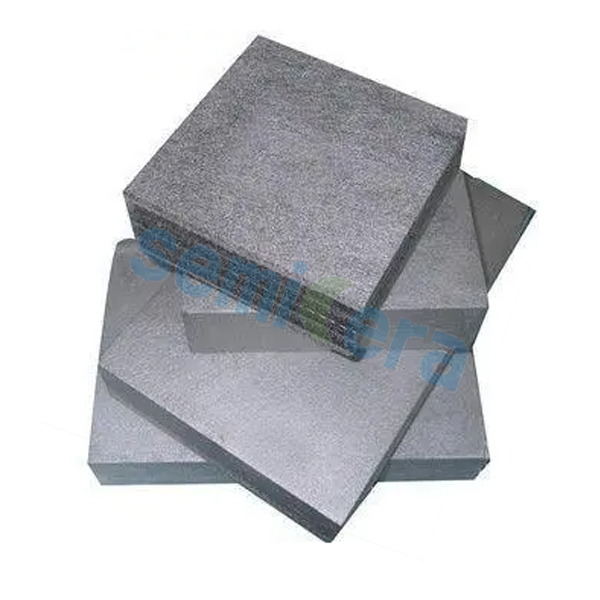

Silicon nitride bonded silicon carbide

Si3N4 bonded SiC ceramic refractory material, is mixed with high pure SIC fine powder and Silicon powder, after slip casting course, reaction sintered under 1400~1500°C. During the sintering course, filling the high pure Nitrogen into the furnace, then the silicon will react with Nitrogen and generate Si3N4,So Si3N4 bonded SiC material is composed of silicon nitride (23%) and silicon carbide(75%) as main raw material,mixed with organic material,and shaped by mixture, extrusion or pouring,then made after drying and nitrogenization.

Features and advantages:

1. High temperature tolerance

2.High thermal conductivity and shock resistance

3.High mechanical strength and abrasion resistance

4.Excellent energy efficiency and corrosion resistance

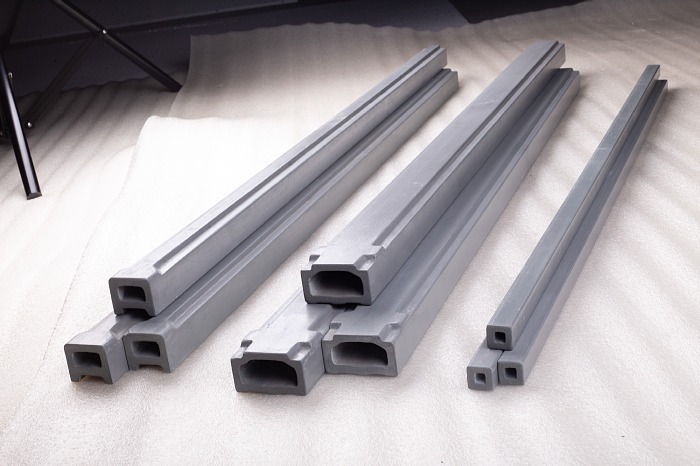

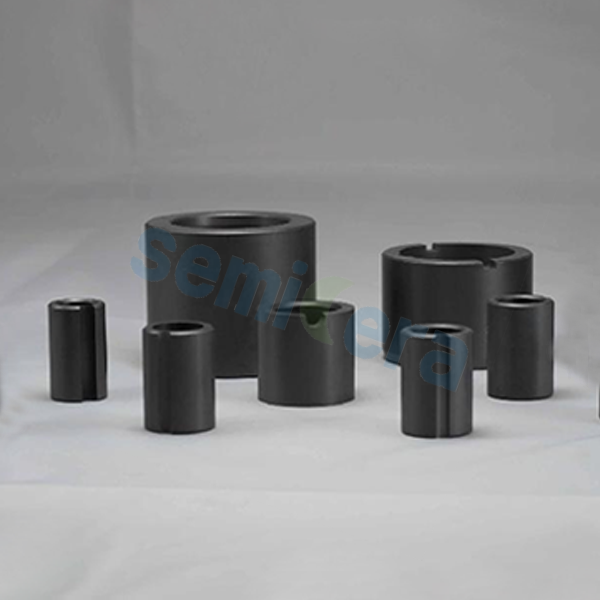

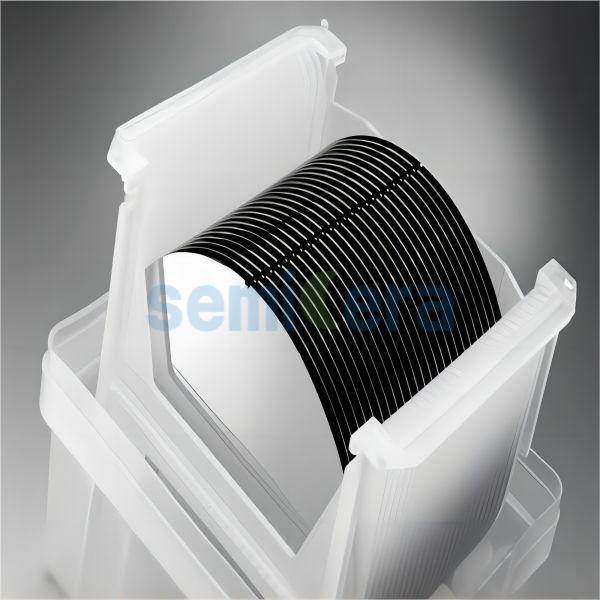

We provide high quality and precision machined NSiC ceramic components which process by

1.Slip casting

2.Extruding

3.Uni Axial Pressing

4.Isostatic Pressing

Material Datasheet

| >Chemical Composition | Sic | 75% |

| Si3N4 | ≥23% | |

| Free Si | 0% | |

| Bulk density (g/cm3) | 2.70~2.80 | |

| Apparent porosity (%) | 12~15 | |

| Bend strength at 20 ℃(MPa) | 180~190 | |

| Bend strength at 1200 ℃(MPa) | 207 | |

| Bend strength at 1350 ℃(MPa) | 210 | |

| Compressive strength at 20 ℃(MPa) | 580 | |

| Thermal conductivity at 1200 ℃(w/m.k) | 19.6 | |

| Thermal expansion coefficient at1200 ℃(x 10-6/C) | 4.70 | |

| Thermal shock resistance | Excellent | |

| Max. temperature (℃) | 1600 | |