Silicon Carbide Sliding Bearings from Semicera are designed for exceptional performance in chemical and industrial pumps, as well as stirrers and mixers used in the chemical, pharmaceutical, and food processing industries. These bearings utilize the superior properties of ceramic silicon carbide, including extreme hardness, lightweight, temperature stability, and corrosion resistance, making them ideal for environments handling corrosive media.

Whether it's manual kitchen mixers, rotating mechanical parts, magnetic drives for stirrers, or pumps in chemical plants and equipment manufacturing, sliding bearings from Semicera endure billions of rotations throughout their lifespan. Like roller bearings in machine and equipment manufacturing, sliding bearings are among the most commonly used bearing types, operating on a non-contact principle with minimal gaps between the shaft and impeller, reducing friction. These bearings are exposed to extreme temperature and pressure fluctuations during industrial manufacturing, necessitating continuous lubrication with oil, grease, or the conveyed medium itself.

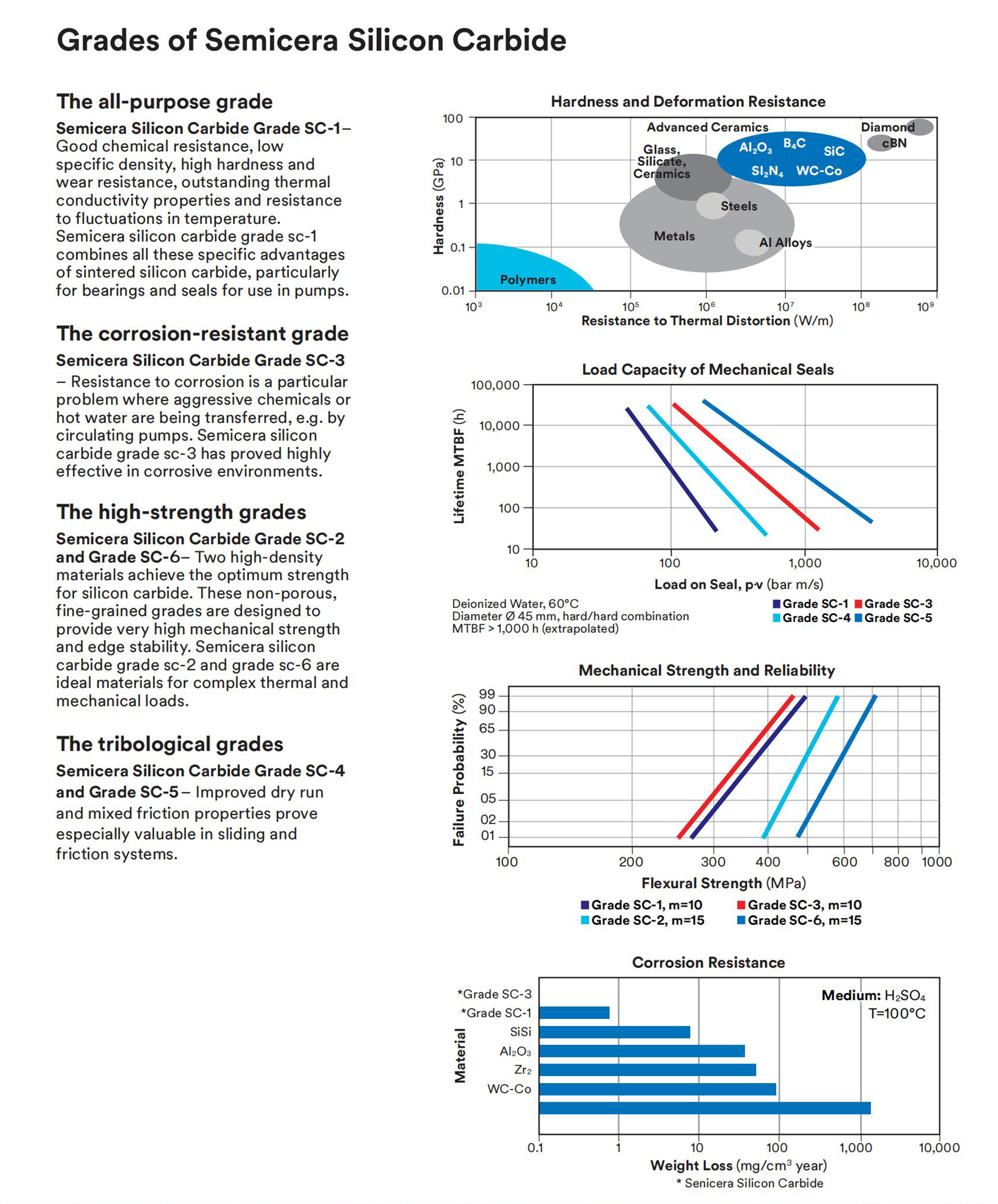

In harsh industrial settings, sliding bearings crafted from silicon carbide (SiC) outperform their metal counterparts, as noted by Georg Victor, Semicera’s Technical Ceramics Product and Application Development Manager. He highlights that the diamond-like crystal structure of ceramic materials provides higher hardness than traditional steels, along with excellent dimensional stability and wear resistance. This significantly extends the maintenance-free lifespan of bearings, reducing lifecycle costs.

In chemical or processing plants, silicon carbide bearings leverage the processed media as their sole lubricant, handling corrosive acids, alkalis, abrasive suspensions, and thermal shocks efficiently. These bearings can even function in mixed friction environments for extended periods without seizing, showcasing extremely low wear rates.

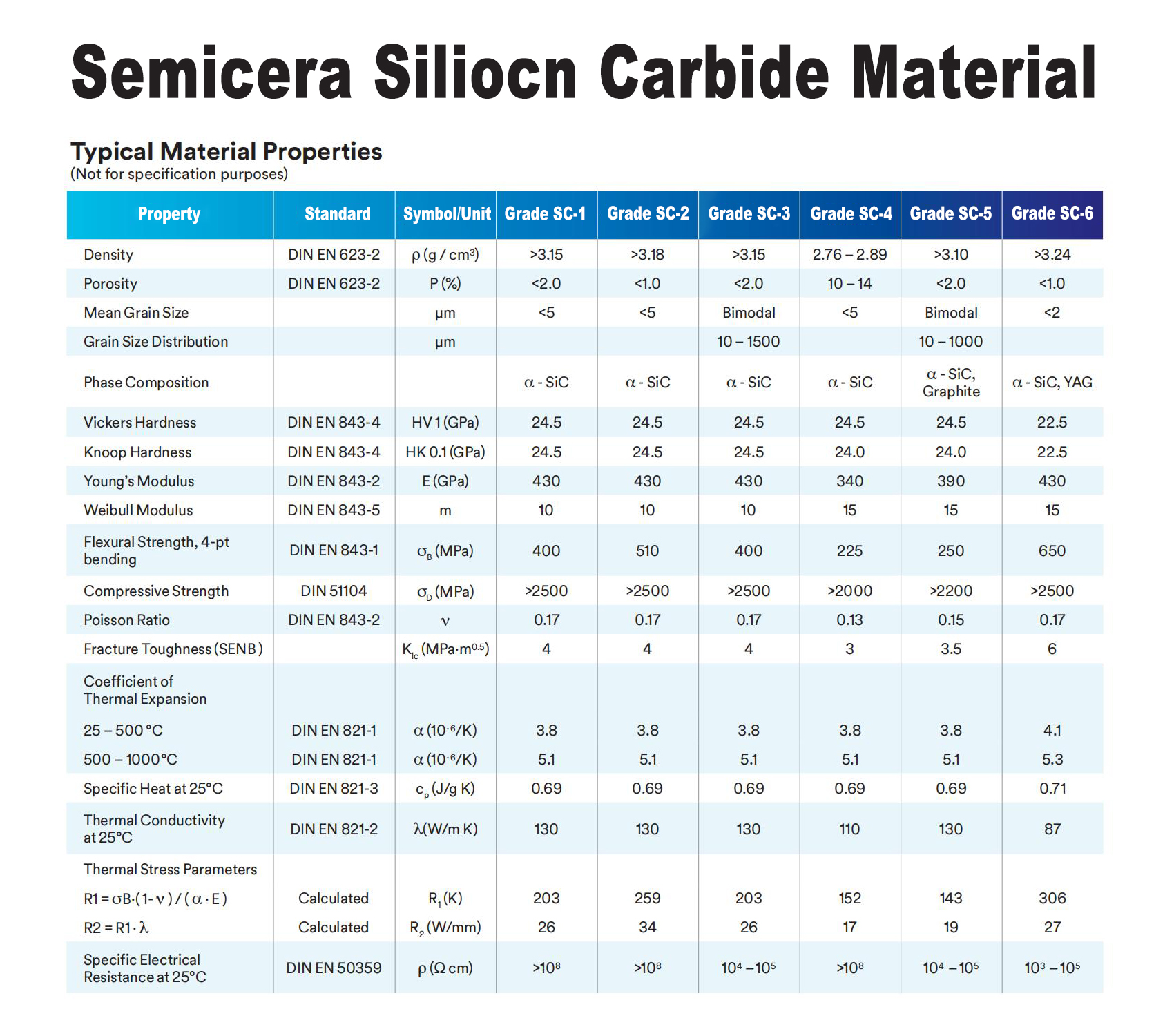

Semicera's silicon carbide sliding bearings are lightweight, reducing centrifugal forces and making them ideal for high-speed and space-saving applications. The ceramic material's properties can be tailored to precise requirements, offering variants like porous SiC, dense SiC, and graphite-containing SiC, with varying grain sizes and densities for different applications. Semicera’s bearings are a testament to advanced material engineering, providing unmatched reliability and performance in demanding environments.

Applications:

-Process fluid-lubricated systems like magnetically coupled pumps and canned motor pumps.

-Support bearings for immersion pumps, agitators, and magnetic drives.

Semicera's silicon carbide sliding bearings have established worldwide success for over three decades, proving their mettle under realistic lubrication and operating conditions.