Description

Semicera's SiC coated graphite susceptors are engineered using high-quality graphite substrates, which are meticulously coated with Silicon Carbide (SiC) through advanced Chemical Vapor Deposition (CVD) processes. This innovative design ensures exceptional resistance to thermal shock and chemical degradation, significantly extending the lifespan of the SiC coated graphite susceptor and guaranteeing reliable performance throughout the semiconductor manufacturing process.

Key Features:

1. Superior Thermal Conductivity The SiC coated graphite susceptor exhibits outstanding thermal conductivity, which is crucial for efficient heat dissipation during semiconductor manufacturing. This feature minimizes thermal gradients on the wafer surface, promoting uniform temperature distribution essential for achieving the desired semiconductor properties.

2. Robust Chemical and Thermal Shock Resistance The SiC coating provides formidable protection against chemical corrosion and thermal shock, maintaining the integrity of the graphite susceptor even in harsh processing environments. This enhanced durability reduces downtime and extends the lifespan, contributing to increased productivity and cost-efficiency in semiconductor manufacturing facilities.

3. Customization for Specific Needs Our SiC coated graphite susceptors can be tailored to meet specific requirements and preferences. We offer a range of customization options, including size adjustments and variations in coating thickness, to ensure design flexibility and optimized performance for different applications and process parameters.

Applications:

ApplicationsSemicera SiC coatings are utilized in various stages of semiconductor manufacturing, including:

1. -LED Chip Fabrication

2. -Polysilicon Production

3. -Semiconductor Crystal Growth

4. -Silicon and SiC Epitaxy

5. -Thermal Oxidation and Diffusion (TO&D)

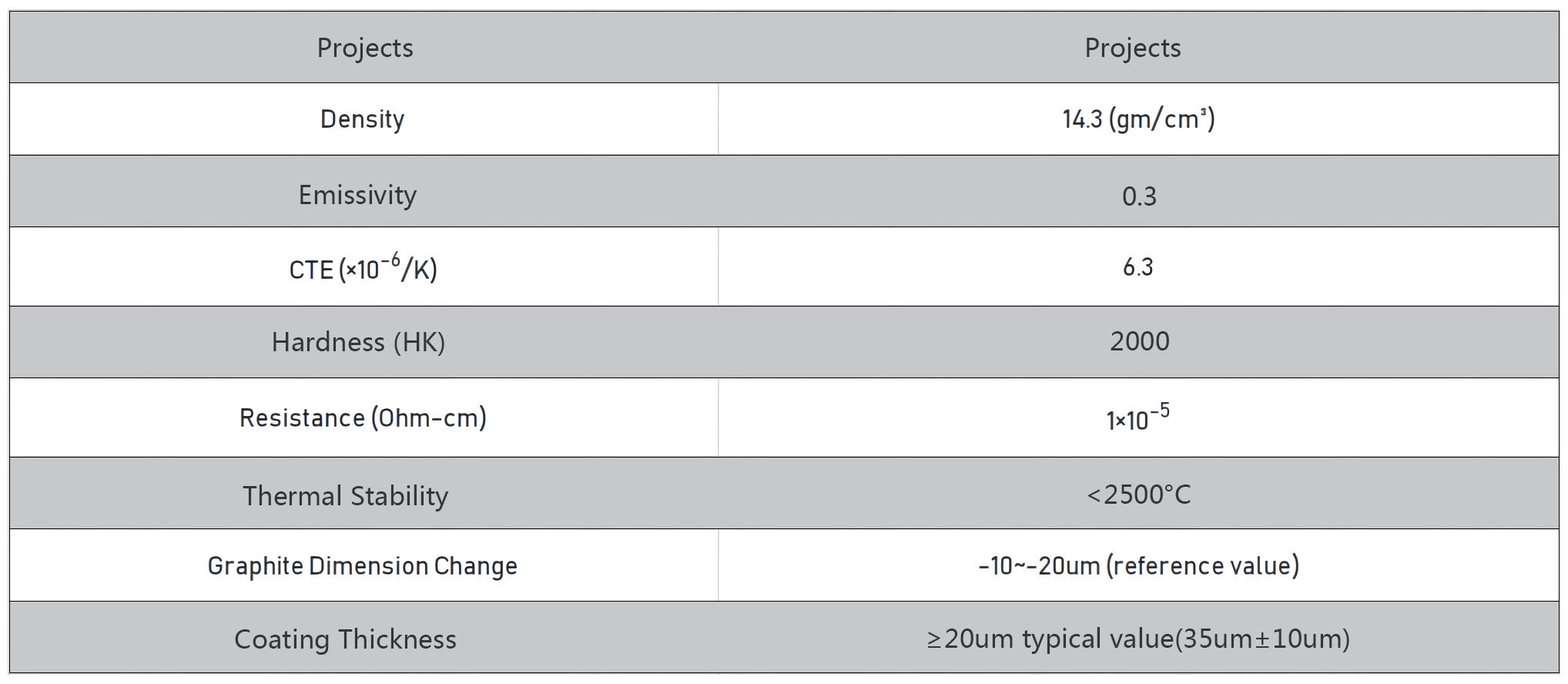

Technical Specifications: