Silicon carbide ceramic tube has excellent high temperature stability and can maintain its structure and performance in extremely high temperature environments. It can withstand high temperatures up to thousands of degrees Celsius, so it has a wide range of uses in high temperature applications. In addition, silicon carbide ceramic tube also has good thermal conductivity and can effectively conduct heat, making it play an important role in the field of thermal management and heat dissipation.

Silicon carbide ceramic tube also exhibits excellent chemical stability and corrosion resistance. It has good resistance to many acids, alkalis and other chemicals, making it widely used in chemical processes, corrosive environments and acid-base treatment. In addition, silicon carbide ceramic tube also has a low coefficient of thermal expansion, which enables it to maintain good stability when the temperature changes.

Silicon carbide ceramic tube has a wide range of applications in many industries. In high-temperature furnaces, heat treatment equipment and burners, silicon carbide ceramic tube can be used as furnace internals, refractory materials and thermal insulation materials. In the chemical industry, it can be used for pipelines, reactors and storage tanks for corrosive media. In addition, silicon carbide ceramic tube is also widely used in semiconductor manufacturing, solar industry, electronic equipment and aerospace.

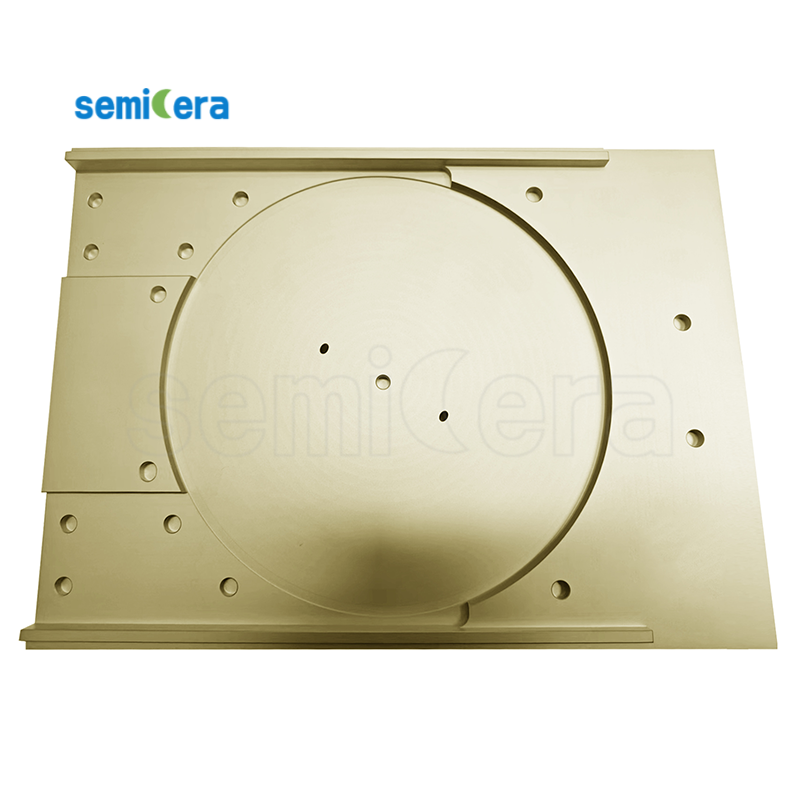

Shape and size can be customized according to requirements

Very high hardness(HV10): 22.2(Gpa)

Very low density (3.10-3.20 g/cm³)

At temperatures up to 1400 ℃, SiC can even maintain its strength

Because of its chemical and physical stability, SiC has high hardness and corrosion resistance.