Silicon carbide seals have excellent high temperature resistance and can withstand extreme temperature changes in high temperature environments without losing sealing performance. It has excellent thermal conductivity and thermal stability, can effectively conduct and disperse heat, thereby reducing thermal stress caused by temperature changes and ensuring the reliability and long life of the seal.

In addition, silicon carbide seals also have excellent corrosion resistance. It can resist corrosion and erosion from various chemicals, including acids, alkalis and solvents. This makes silicon carbide seals very suitable for applications that require high chemical stability, such as chemical, petroleum and food processing industries.

The high hardness and excellent wear resistance of silicon carbide seals are also one of its important features. It can withstand high-speed rotation, friction and wear, maintain sealing effect and extend service life. This makes silicon carbide seals an indispensable key component in many rotating equipment and mechanical systems.

Choosing silicon carbide seals, you will get a high-quality, high-performance sealing solution to ensure the reliable operation of your industrial equipment and systems, and improve production efficiency and safety.

Applications:

-Wear-resistant Field: bushing, plate, sandblasting nozzle,cyclone lining, grinding barrel,etc...

-High Temperature Field: siC Slab, Quenching Furnace Tube,Radiant Tube,crucible,Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat,Kiln car Structure,Setter,etc.

-Military Bulletproof Field

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck,sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway,etc.

-Silicon Carbide Seal Field: all kinds of sealing ring, bearing, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller,etc.

-Lithium Battery Field

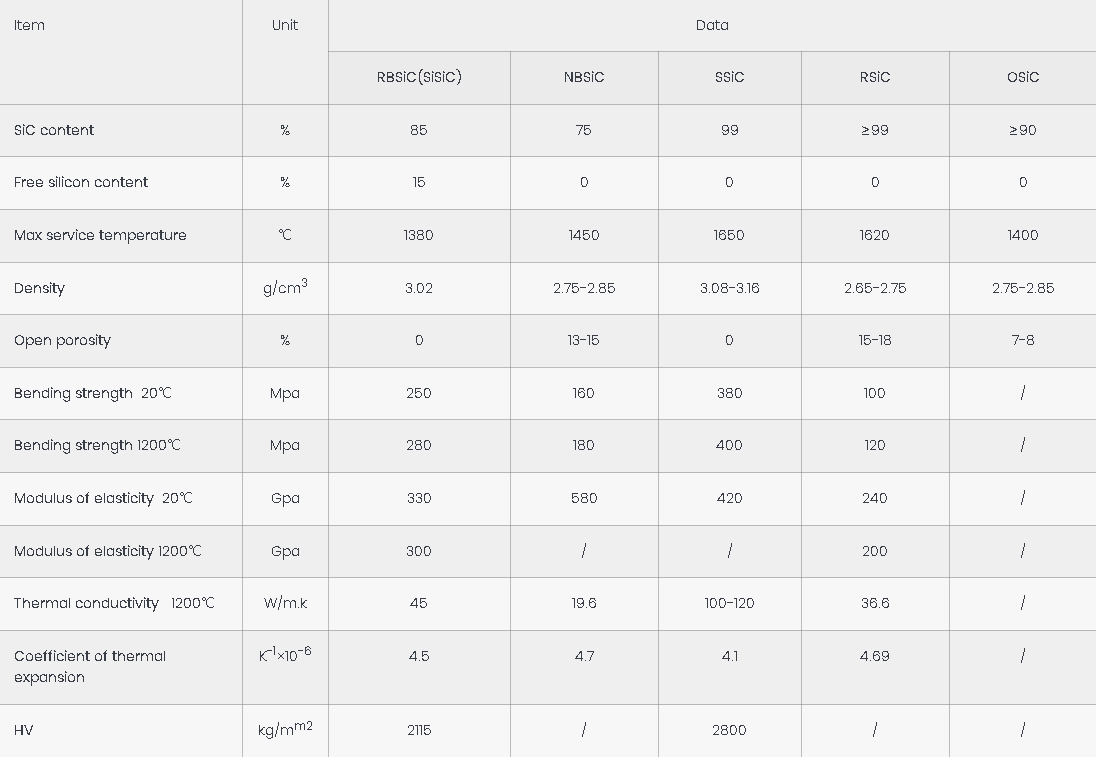

Technical Parameters