SiC micro reaction tubes have excellent high temperature resistance and can operate stably under high temperature conditions. The high thermal conductivity and thermal stability of silicon carbide materials enable the microreactors to quickly conduct and disperse heat, effectively control the reaction temperature, and thus achieve efficient thermal management and temperature control. This provides an ideal environment for high temperature reactions and improves reaction rates and selectivity.

In addition, SiC micro reaction tubes have excellent chemical stability and can resist erosion and corrosion from a variety of chemicals. SiC micro reaction tubes has good tolerance to common reactants such as acids, bases, and solvents, thereby ensuring the long life and reliability of the reaction tube. The inert surface of silicon carbide materials also reduces unnecessary reactant adsorption and contamination, maintaining the purity and consistency of the reaction.

The micro design of SiC micro reaction tubes gives them a high surface area to volume ratio, providing higher reaction efficiency and faster reaction rates. The microchannel structure of the microreactor enables a high degree of fluid control and mixing, thereby achieving precise reaction conditions and uniform material exchange. This makes SiC micro reaction tubes have great potential in applications such as microfluidics, drug synthesis, catalytic reactions, and biochemical analysis.

The customizability and compatibility of SiC micro reaction tubes make them suitable for a variety of laboratory and industrial applications. They can be integrated with traditional laboratory equipment and automation systems to achieve high-throughput and high-efficiency reaction processes. The reliability and precision of SiC micro reaction tubes make them an ideal choice for researchers and engineers to innovate and optimize.

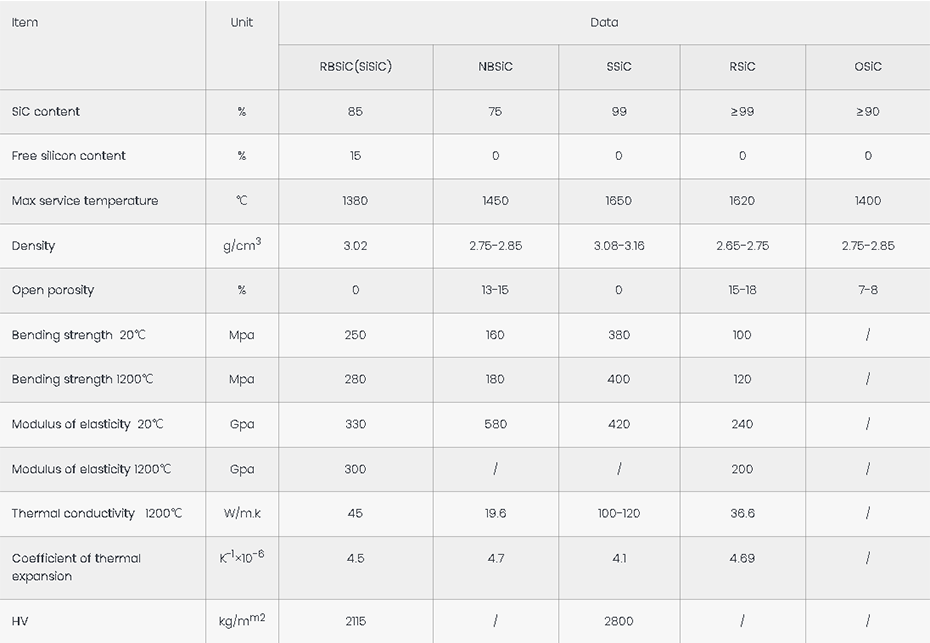

Technical Parameters: