Description

Semicera's SiC Wafer Susceptors for MOCVD (Metal-Organic Chemical Vapor Deposition) are engineered to meet the exacting demands of epitaxial deposition processes. Utilizing high-quality Silicon Carbide (SiC), these susceptors offer unparalleled durability and performance in high-temperature and corrosive environments, ensuring the precise and efficient growth of semiconductor materials.

Key Features:

1. Superior Material Properties Constructed from high-grade SiC, our wafer susceptors exhibit exceptional thermal conductivity and chemical resistance. These properties enable them to withstand the extreme conditions of MOCVD processes, including high temperatures and corrosive gases, ensuring longevity and reliable performance.

2. Precision in Epitaxial Deposition The precise engineering of our SiC Wafer Susceptors ensures uniform temperature distribution across the wafer surface, facilitating consistent and high-quality epitaxial layer growth. This precision is critical for producing semiconductors with optimal electrical properties.

3. Enhanced Durability The robust SiC material provides excellent resistance to wear and degradation, even under continuous exposure to harsh process environments. This durability reduces the frequency of susceptor replacements, minimizing downtime and operational costs.

Applications:

Semicera's SiC Wafer Susceptors for MOCVD are ideally suited for:

• Epitaxial growth of semiconductor materials

• High-temperature MOCVD processes

• Production of GaN, AlN, and other compound semiconductors

• Advanced semiconductor manufacturing applications

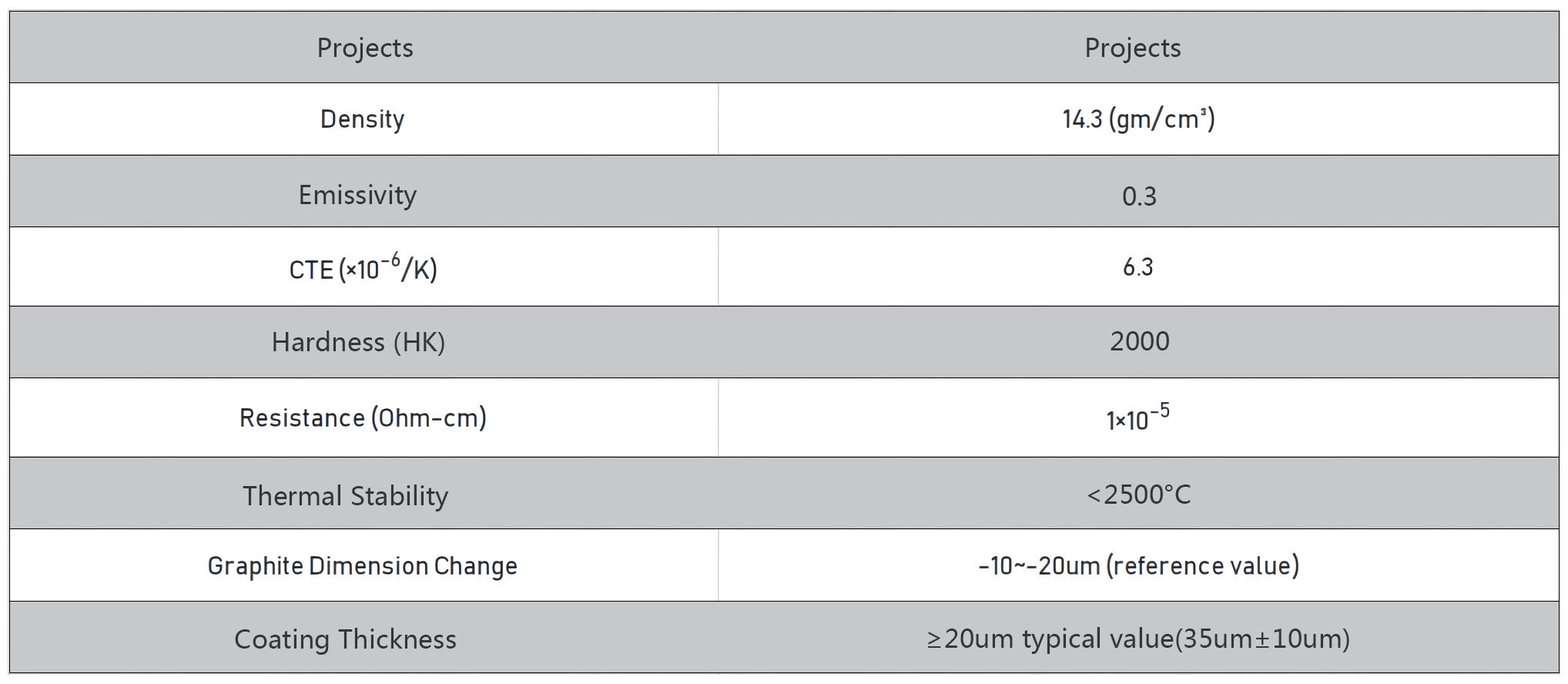

Main Specifications of CVD-SIC Coatings:

Benefits:

• High Precision: Ensures uniform and high-quality epitaxial growth.

• Long-Lasting Performance: Exceptional durability reduces replacement frequency.

• Cost-Efficiency: Minimizes operational costs through reduced downtime and maintenance.

• Versatility: Customizable to fit various MOCVD process requirements.