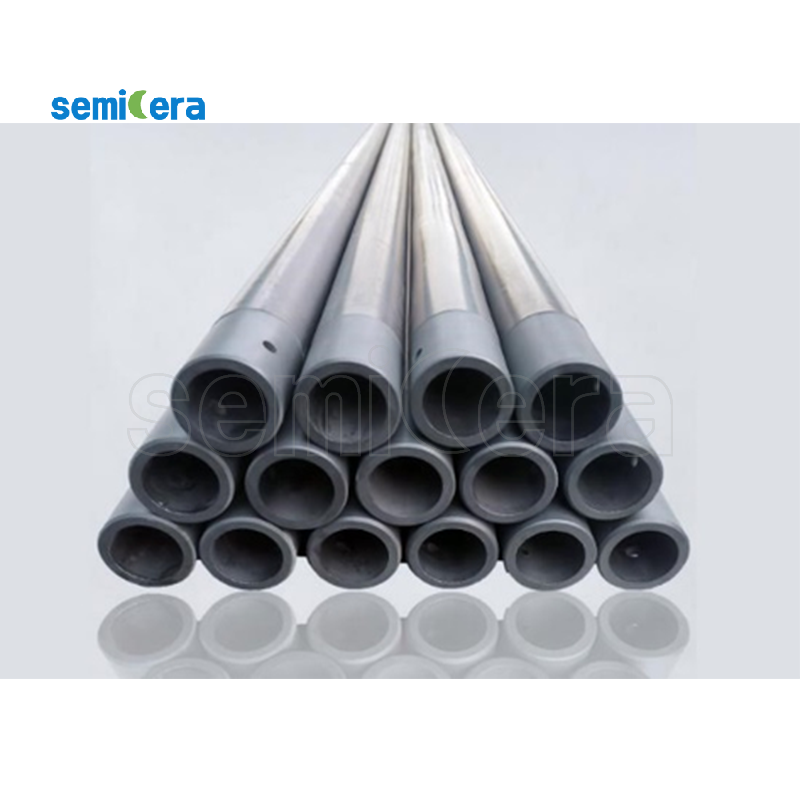

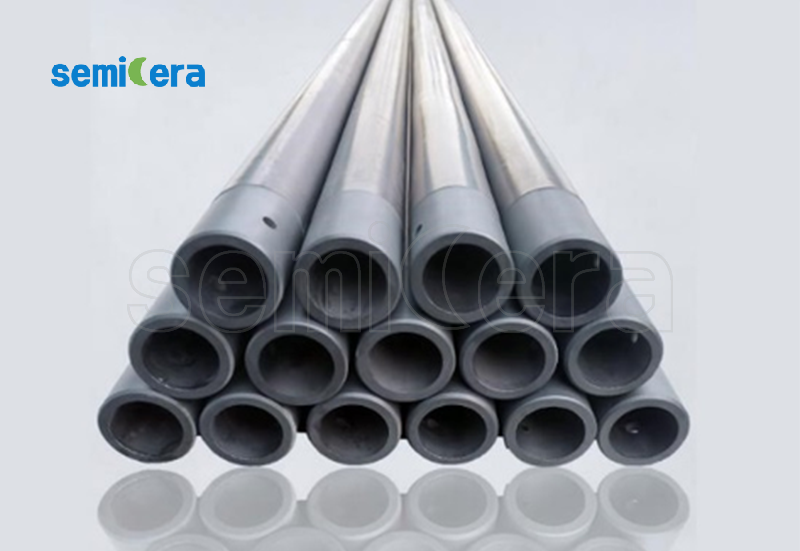

SiC ceramic rollers have excellent wear resistance and can withstand high pressure and friction without losing surface quality. Its hardness is close to that of diamond, which enables it to effectively reduce contact wear with metal materials and extend the service life of the roller. The low friction coefficient of SiC ceramic rollers also reduces energy loss and heat generation, improving production efficiency.

In addition, SiC ceramic rollers have excellent high temperature resistance. It can operate stably in high temperature environments without softening or deformation. This makes SiC ceramic rollers very suitable for high temperature processing processes such as metal hot rolling and continuous casting, ensuring that the rollers maintain excellent performance and dimensional stability under extreme temperatures.

SiC ceramic rollers also have excellent corrosion resistance. It can resist the erosion of chemicals such as acids, alkalis, solvents and corrosive gases, maintaining the surface finish and functionality of the rollers. This makes SiC ceramic rollers perform well in applications such as chemical processing and electroplating, extending the service life of equipment and improving production quality.

The lightweight characteristics of SiC ceramic rollers give them excellent inertial characteristics and vibration reduction capabilities, thereby reducing vibration and noise, improving equipment stability and operating comfort. Its precise dimensions and flat surface ensure roller stability and smoothness, providing excellent results for metalworking and printing processes.

Non-pressure sintered silicon carbide roller, atmospheric pressure sintered silicon carbide ceramic products, the use of high purity ultra-fine silicon carbide powder, sintered at 2450℃ high temperature, silicon carbide content of more than 99.1%, product density ≥3.10g/cm3, no metal impurities such as metal silicon.

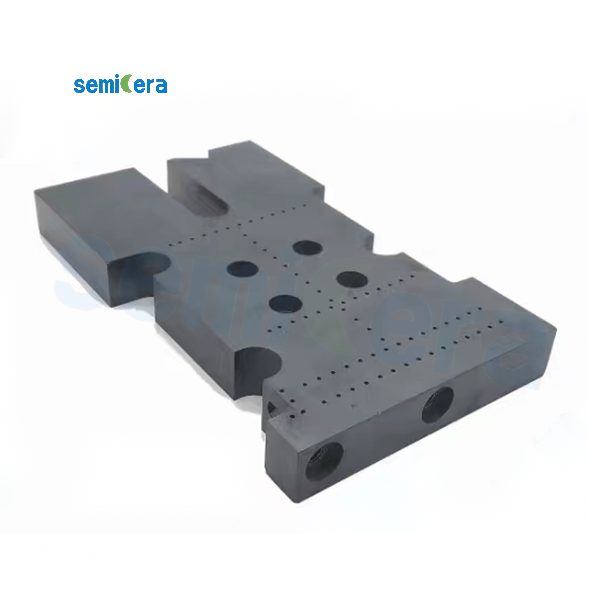

► Silicon carbide content --≥99%;

► High temperature resistance - normal use at 1800℃;

► High thermal conductivity - comparable to the thermal conductivity of graphite materials;

► High hardness - hardness second only to diamond, cubic boron nitride;

► Corrosion resistance - strong acid and alkali do not have any corrosion, corrosion resistance is better than tungsten carbide and alumina;

► Light weight - density 3.10g/cm3, close to aluminum;

► No deformation - very small coefficient of thermal expansion;

► Thermal shock resistance - the material can withstand rapid temperature changes, thermal shock resistance, resistance to cold and heat, stable performance.

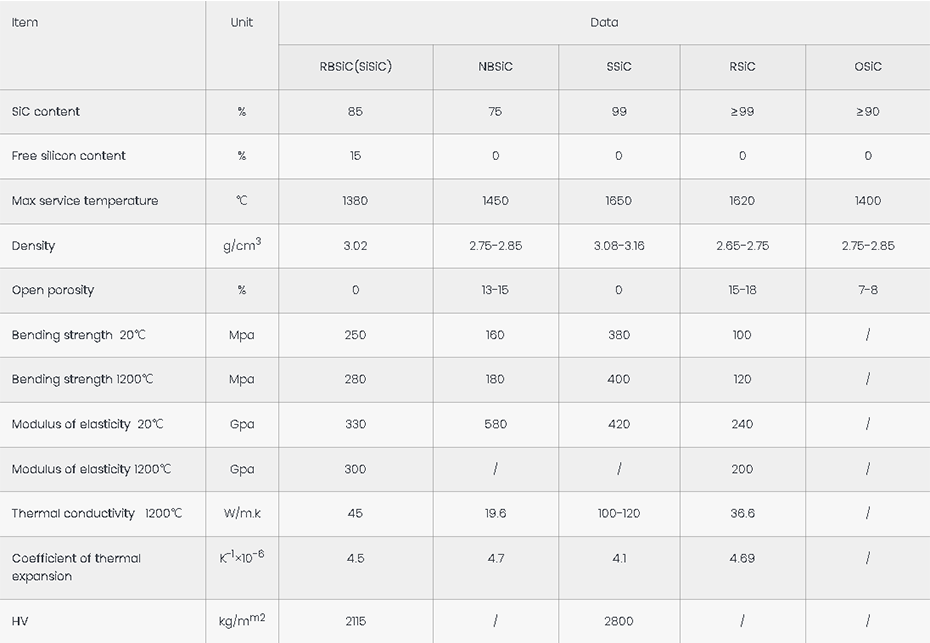

Technical Parameters: