Zirconia is a material with high mechanical strength and fracture toughness at room temperature. Our zirconia (ZrO2) is added with 3mol%Y2O3 partial stable zirconia (PSZ). Because the particle diameter of PSZ material is small, it can be processed with high precision, and its application in precision machining parts such as molds is expanding. In addition, can also be used for industrial tools, optical connector parts and crushing equipment medium. The high fracture toughness of PSZ can be used to make special springs, and it is also widely used in domestic ceramic knives, slicer and other parts.

The main characteristics of zirconia ceramic parts:

1. Excellent wear resistance, much higher 276 times than stainless steel

2. Higher density than most technical ceramics, over than 6 g/cm3

3. High hardness, over 1300 MPa for Vicker

4. Can withstand higher temperatures up to 2400°

5. Low thermal conductivity, less than 3 W/m.k at room temperature

6. Similar coefficient of thermal expansion as stainless steel

7. Exceptional fracture toughness reaches up to 8 Mpa m1/2

8. Chemical inertness, aging resistance, and not rust forever

9. Resistance to molten metals due to an extraordinary melting point.

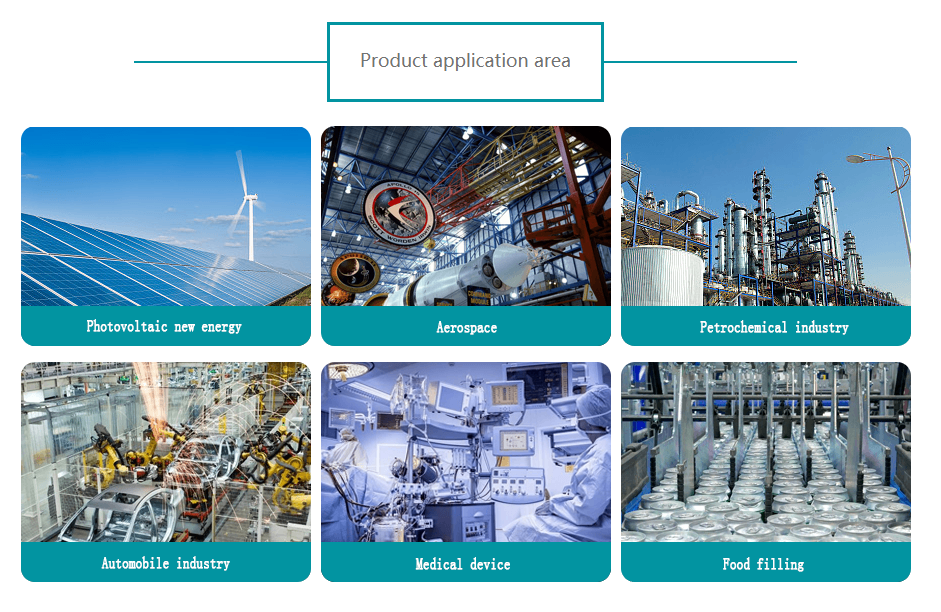

Zirconia (ZrO2) I main uses

Mold and mould tools (various molds, precision positioning fixture, insulation fixture); Mill parts (classifier, air flow mill, bead mill); Industrial tool (industrial cutter, slitter machine, flat press roll); Optical connector components (sealing ring, sleeve, V-groove fixture); Special spring (coil spring, plate spring); Consumer products (small insulated screwdriver, ceramic knife, slicer).