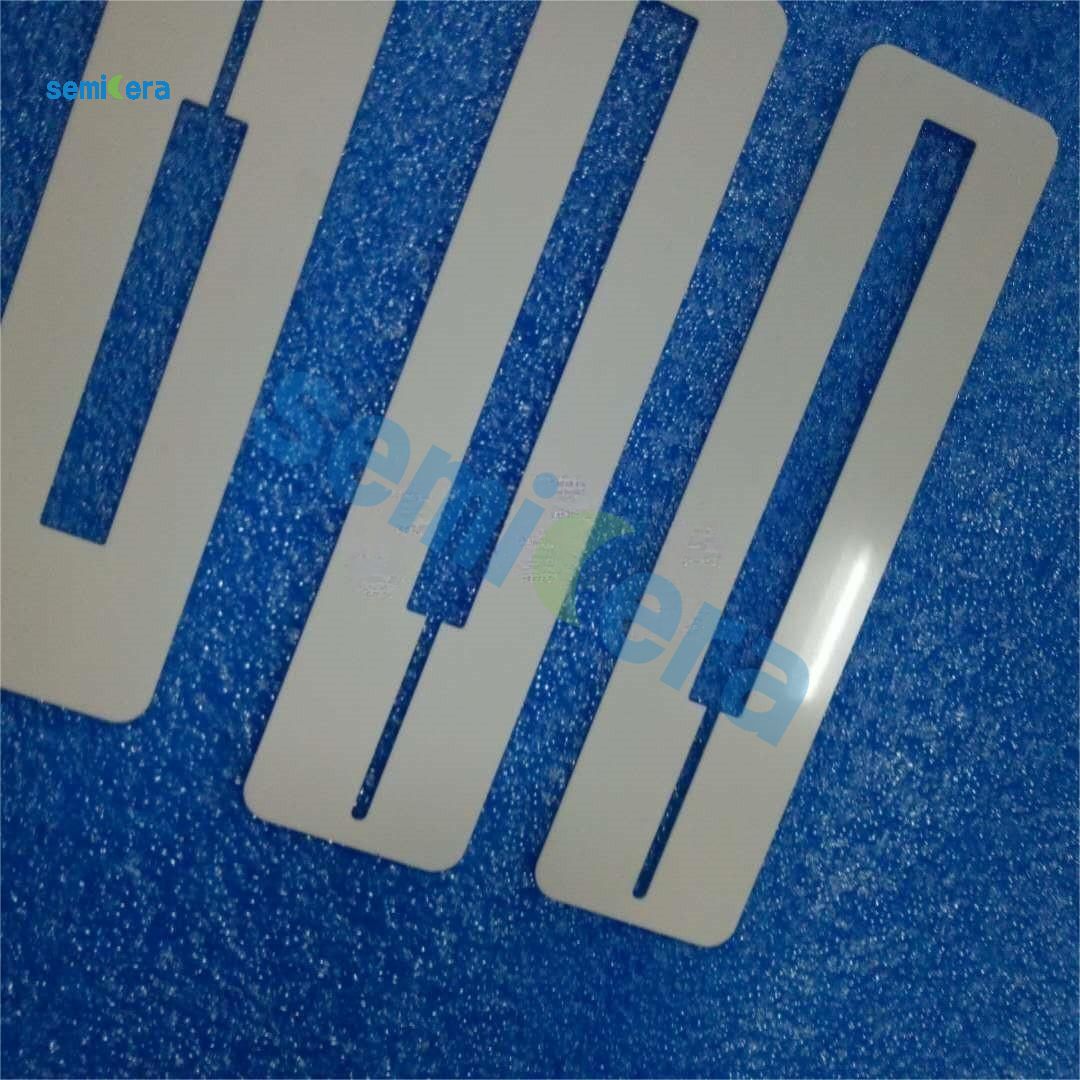

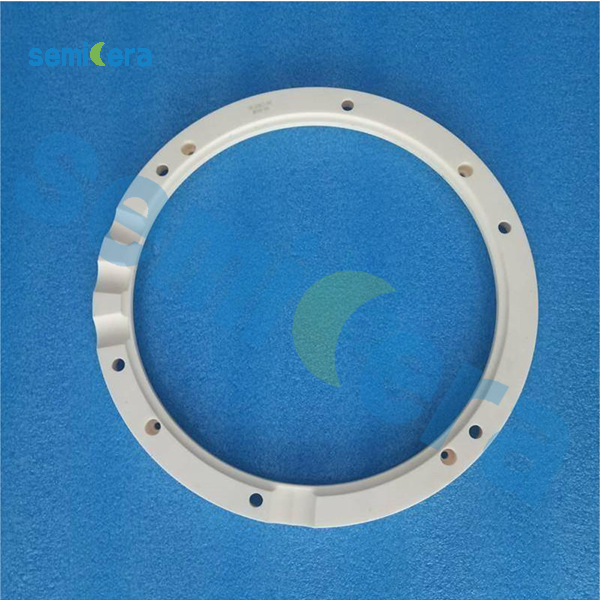

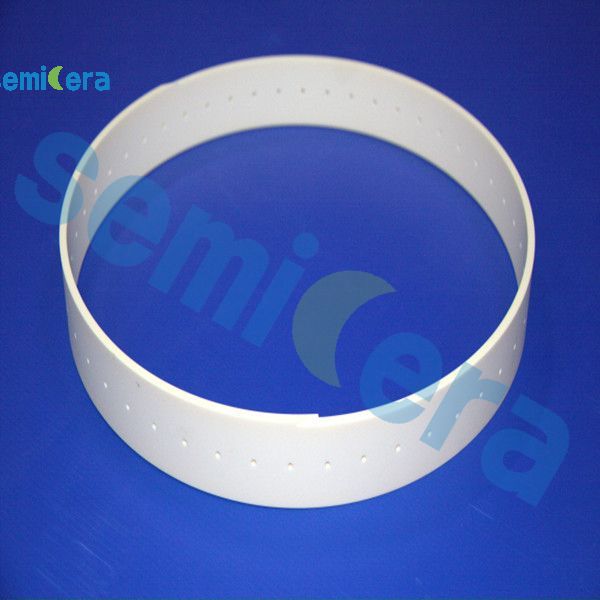

Alumina ceramics

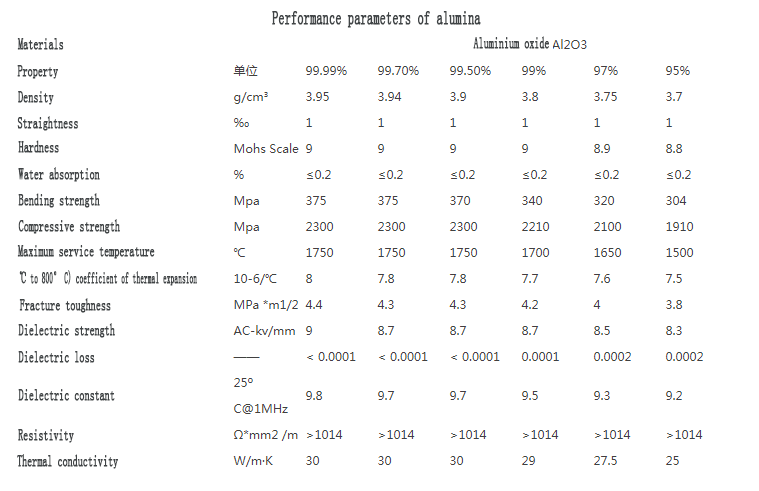

1. High hardness

Rockwell hardness is HRA80-90, the hardness is lower than diamond, far more than the wear resistance of wear-resistant steel and stainless steel.

2. Excellent wear resistance

Measured by professional research institutions, its wear resistance is equivalent to 266 times of manganese steel. Gaoming cast iron 171.5 times, according to our more than ten years of customer tracking survey, under the same working conditions, can extend the service life of the equipment at least ten times more.

3. Light weight

Its density of 3.5g/cm3 is only half that of steel, which can greatly reduce equipment load.

Features:

High mechanical strength

High resistivity and good insulation

Mohs hardness of 9 and excellent wear resistance

High melting points and corrosion resistance

Good stability

Optical properties

Ionic conductivity

Application industry: Machinery, electronic, chemical, petroleum etc.

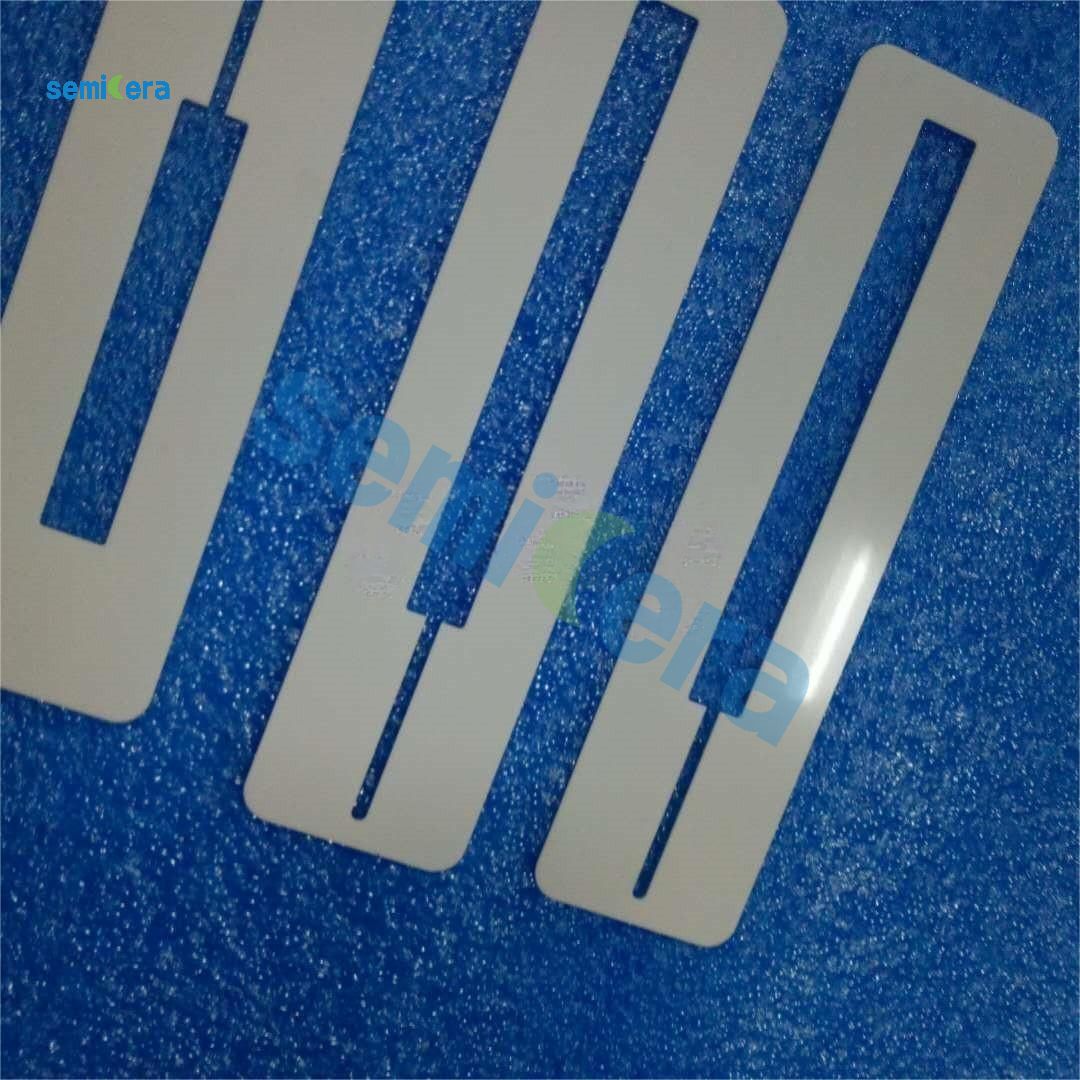

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.