RTP CVD SiC rings are widely used in industrial and scientific fields in high temperature and corrosive environments. It plays an important role in semiconductor manufacturing, optoelectronics, precision machinery and chemical industry. Specific applications include:

1. Semiconductor manufacturing: RTP CVD SiC rings can be used for heating and cooling of semiconductor equipment, providing stable temperature control and ensuring the accuracy and consistency of the process.

2. Optoelectronics: Due to its excellent thermal conductivity and high temperature resistance, RTP CVD SiC rings can be used as support and heat dissipation materials for lasers, fiber optic communication equipment and optical components.

3. Precision machinery: RTP CVD SiC rings can be used for precision instruments and equipment in high temperature and corrosive environments, such as high temperature furnaces, vacuum devices and chemical reactors.

4. Chemical industry: Due to its corrosion resistance and chemical stability, RTP CVD SiC rings can be used in containers, pipes and reactors in chemical reactions and catalytic processes.

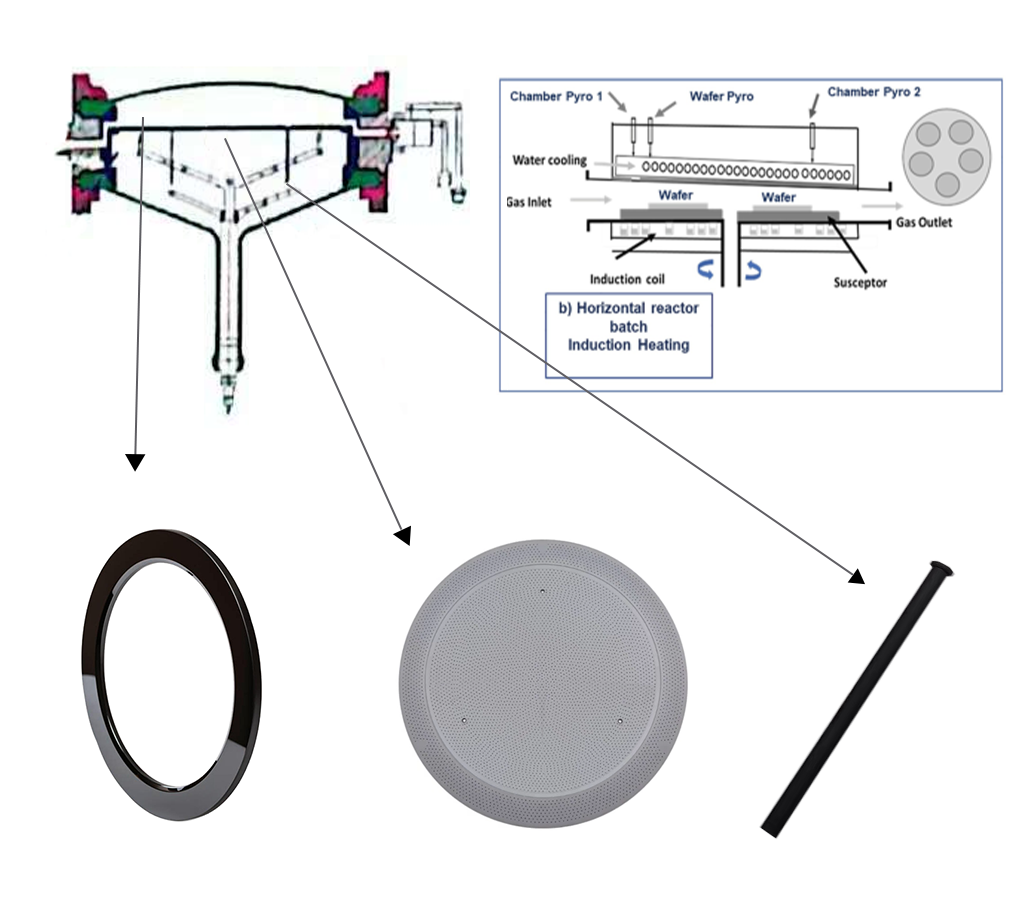

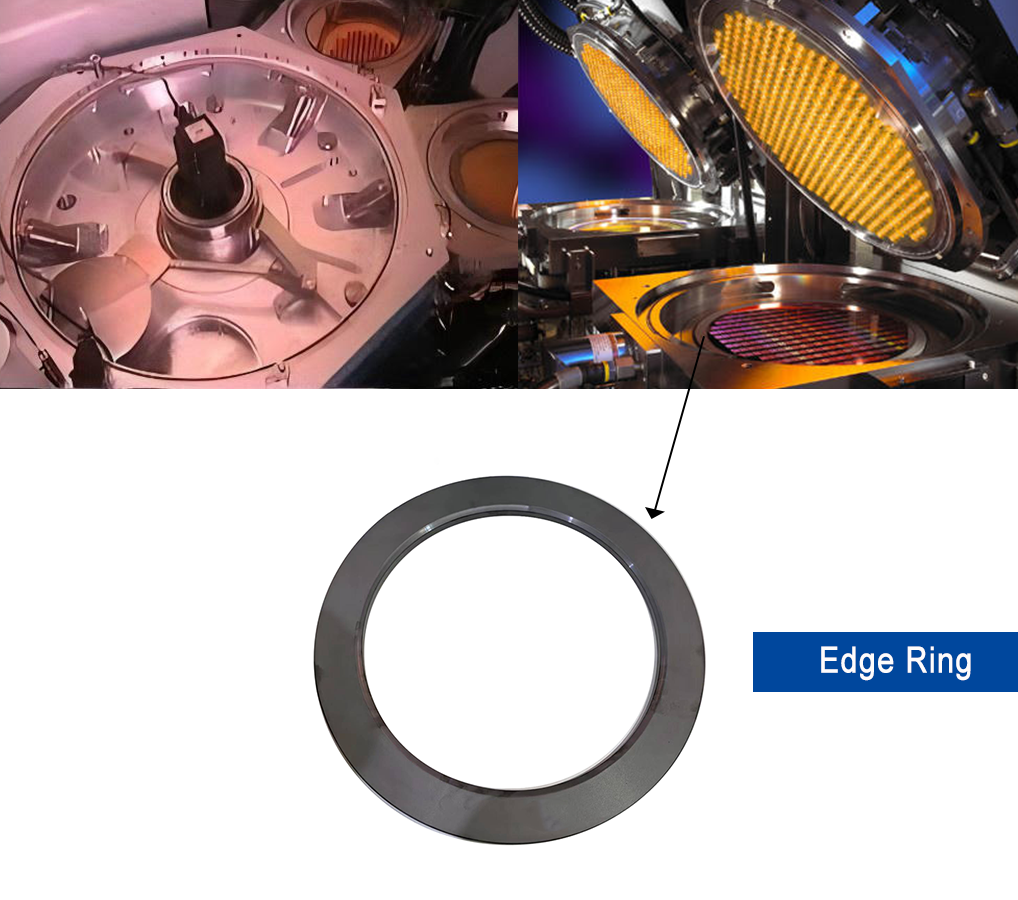

Epi System

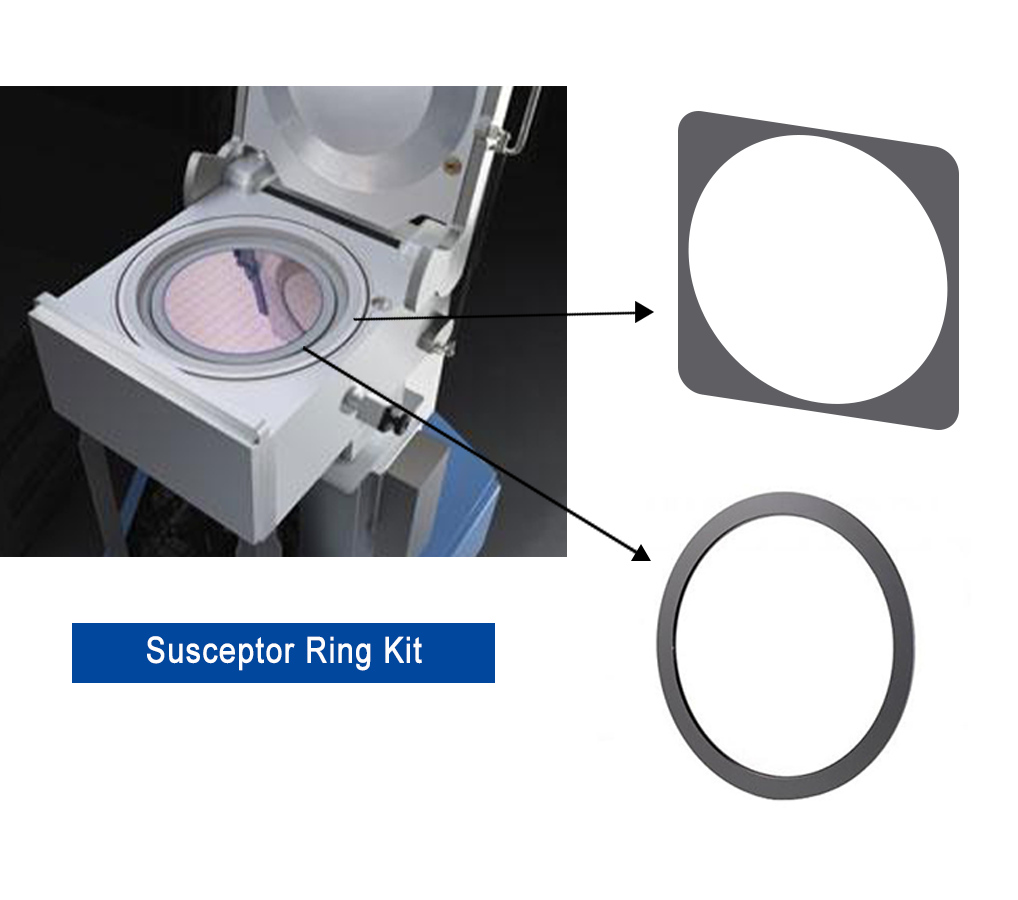

RTP System

CVD System

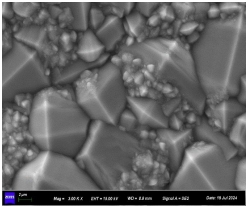

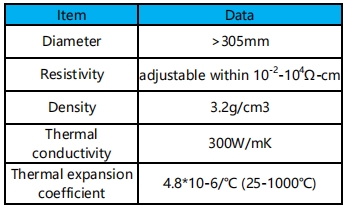

Product performance:

1. Meet the process below 28nm

2. Super corrosion resistance

3. Super clean performance

4. Super hardness

5. High density

6. High temperature resistance

7. Wear resistance

Product application:

Silicon carbide materials have the characteristics of high hardness, wear resistance, corrosion resistance and high temperature stability. Products with excellent comprehensive performance are widely used in dry etching and TF/Diffusion processes.

Product performance:

1. Meet the process below 28nm

2. Super corrosion resistance

3. Super clean performance

4. Super hardness

5. High density

6. High temperature resistance

7. Wear resistance

Composite process development:

• Graphite +SiC Coating

• Solide CVD SiC

• Sintered SiC+CVD

• SicSintered SiC

Multiple product type development:

• Ring

• Table

• Susceptor

• Shower Head