The Rigid Felt Crucible by Semicera is crafted to meet the demanding needs of high-temperature environments, combining durability, excellent thermal insulation, and structural integrity. Made from high-quality Rigid Felt, this crucible is engineered to deliver superior heat stability and abrasion resistance, ensuring reliability and long-term performance. Its high-purity composition and low thermal conductivity make it an ideal solution for industries that require precise control of extreme temperatures, including semiconductor manufacturing, metallurgy, and advanced materials processing.

Engineered with Advanced Materials for Optimal Performance

The Semicera Rigid Felt Crucible integrates specialized materials such as Isostatic Graphite, Porous Graphite, and Graphite Foil to enhance heat stability and minimize thermal loss. These materials are known for their high purity and exceptional thermal shock resistance, allowing the crucible to maintain its shape and strength under intense heat. The combination of Rigid Felt and other advanced components like Soft Felt and C/C Composite gives the crucible outstanding insulation properties, reducing the risk of contamination and wear in high-precision processes.

Product details

|

Product name |

Graphite Felt |

|

Chemical Composition |

Carbon fiber |

|

Bulk density |

0.12-0.14g/cm3 |

|

Carbon content |

>=99% |

|

Tensile Strength |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0.08~0.14W/mk |

|

Ash |

<=0.005% |

|

Crushing stress |

8-10N/cm |

|

Thickness |

1-10mm |

|

Processing temperature |

2500(℃) |

There are currently four grades available to provide raw or processed products:

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Available Size:

Plate: 1500*1800(Max) Thickness 20-200mm

Round Drum: 1500*2000(Max) Thicknes 20-150mm

Square Drum: 1500*1500*2000(Max) Thickness 60-120mm

Applicative Temperature Range : 1250-2600

Applications in the Semiconductor Industry

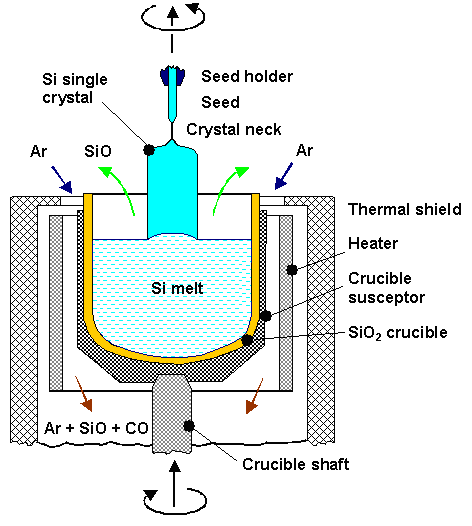

In the semiconductor industry, the Semicera Rigid Felt Crucible is indispensable in high-temperature processes such as wafer fabrication, crystal growth, and chemical vapor deposition. Its high-purity Rigid Felt material ensures minimal contamination risk, making it well-suited for cleanroom environments and precise thermal applications. The crucible’s durability and abrasion resistance are particularly valuable for semiconductor equipment that undergoes frequent thermal cycling, as it helps maintain product consistency and efficiency over time.

Additionally, the Semicera Rigid Felt Crucible serves as a key component in processes involving graphite foils, porous graphite, and C/C composites used in semiconductor manufacturing, supporting the integrity and quality of semiconductor wafers and components.

Exceptional Heat Resistance and Wear Durability

With its high thermal stability and abrasion resistance, the Rigid Felt Crucible by Semicera is built to handle the most demanding environments with ease. Its resilience to extreme heat and abrasive conditions ensures that it withstands long-term use without degradation, making it ideal for applications that require consistent high-temperature performance and low maintenance.

High-Purity Solution for Advanced Industrial Processes

Engineered with the highest standards of purity and performance, the Semicera Rigid Felt Crucible provides a reliable, durable, and high-performance solution for industries that demand rigorous quality and durability. From the precise needs of semiconductor production to other high-tech industries requiring exacting thermal control, this crucible is designed to enhance operational efficiency and product quality.

Choose the Rigid Felt Crucible by Semicera for advanced thermal stability, abrasion resistance, and high-purity solutions across critical high-temperature applications.