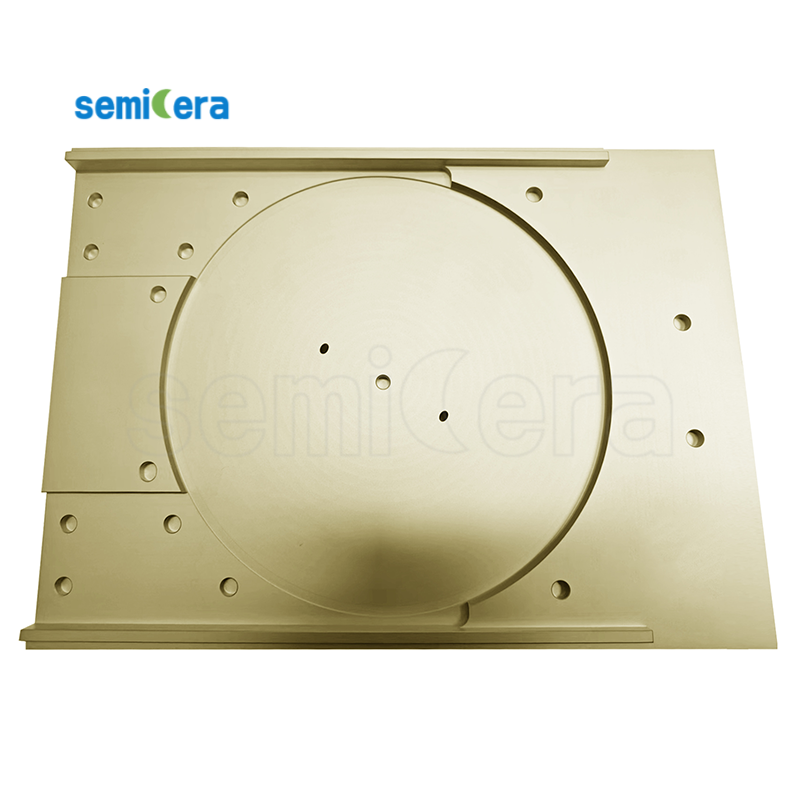

Our Quartz Tank for Wet Processing is crafted from high-purity quartz, renowned for its exceptional resistance to chemicals and high temperatures, which are essential for both wet chemical etching processes and dry etch wet etch applications. Whether you’re performing wet etching or using it as a quartz bath for cleaning, this product guarantees long-lasting performance thanks to its high hardness and wear resistance.

For industries that require the highest standards in wafer cleaning methods, the Semicera Quartz Tank delivers optimal results. It ensures wafers are thoroughly cleaned and prepared for subsequent stages of processing, reducing contamination risks and improving yields. Whether it’s used for cleaning or in wet chemical etching processes, this quartz tank offers unmatched reliability in demanding environments.

In semiconductor manufacturing, where precision is critical, the Quartz Tank for Wet Processing provides the resilience needed to withstand aggressive chemicals while maintaining structural integrity. The Semicera tank is specifically built to endure the challenges of wafer cleaning and wet etching, helping manufacturers streamline their processes and maintain product quality.

Choose Semicera's Quartz Tank for Wet Processing to experience superior durability and effectiveness in your semiconductor production, offering enhanced wear resistance and a long lifespan for lower operational costs.

We can handle various shapes according to your needs, ranging from large single and double quartz baths to small quartz crucibles. In addition to quartz materials, we can also process containers made of hard glass.