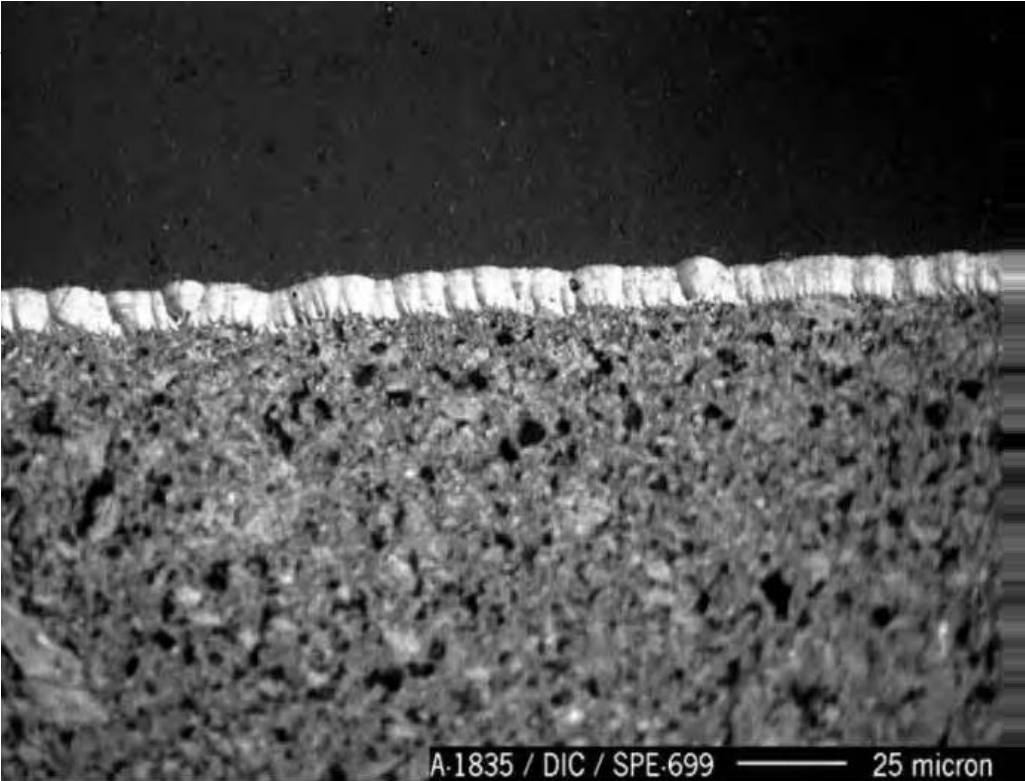

Pyrolytic carbon coating is a thin layer of pyrolytic carbon coated on the surface of highly purified isostatic graphite using chemical vapor deposition (CVD) technology. It has high density, high purity, and anisotropic thermal, electrical, magnetic, and mechanical properties.

Mainfeatures:

1. The surface is dense and free of pores.

2. High purity, total impurity content<20ppm,good airtightness.

3. High temperature resistance, strength increases with increasing usage temperature, reaching the highest value at 2750 ℃,sublimation at 3600 ℃.

4. Low elastic modulus, high thermal conductivity, low thermal expansion coefficient, and excellent thermal shock resistance.

5. Good chemical stability, resistant to acid, alkali, salt, and organic reagents, and has no effect on molten metals, slag, and other corrosive media. It does not oxidize significantly in the atmosphere below 400 ℃, and the oxidation rate significantly increases at 800 ℃.

6. Without releasing any gas at high temperatures, it can maintain a vacuum of 10-7mmHg at around 1800 ℃.

Productapplication:

1. Melting crucible for evaporation in semiconductor industry.

2. High power electronic tube gate.

3. Brush that contacts the voltage regulator.

4. Graphite monochromator for X-ray and neutron.

5. Various shapes of graphite substrates andatomic absorption tube coating.

Pyrolytic carbon coating effect under a 500X microscope, with intact and sealed surface.