The raw materials used in toner production usually include flake graphite, petroleum coke and microcrystalline stone ink. The higher the purity of graphite, the higher the use value. Graphite purification methods can be divided into physical methods and chemical methods. Physical purification methods include flotation and high temperature purification, and chemical purification methods include acid-base method, hydrofluoric acid method and chloride roasting method.

Among them, the high temperature purification method can make use of the high melting point (3773K) and boiling point of graphite to achieve 4N5 and higher purity, which involves evaporation and emission of impurities with low boiling point, so as to achieve the purpose of purification [6]. The key technology of high purity toner is the removal of trace impurities. Combined with the characteristics of chemical purification and high temperature purification, a unique segmented composite high temperature thermochemical purification process is adopted to achieve the purification of high purity toner materials, and the product purity can be more than 6N.

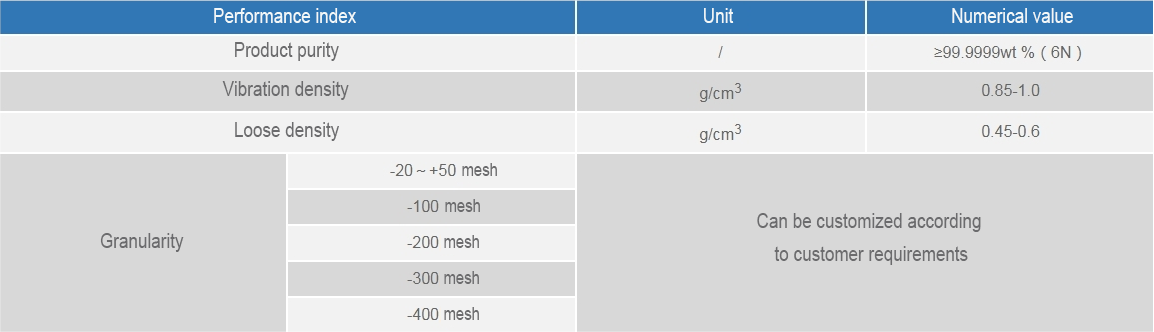

Product performance and features:

1, product purity ≥99.9999% (6N);

2, high purity carbon powder stability, high degree of graphitization, less impurities;

3, granularity and type can be customized according to users.

Main uses of the product:

■ Synthesis of high purity SiC powder and other solid phase synthetic carbide materials

■ Grow diamonds

■ New thermal conductivity materials for electronic products

■ High-end lithium battery cathode material

■ Precious metal compounds are also raw materials