Quartz: A Vital Component in Modern Electronics

Introduction to Quartz Materials

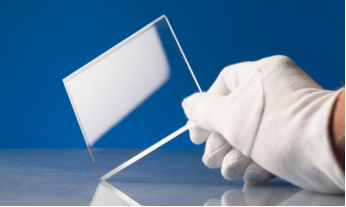

Quartz (SiO₂) may resemble glass at first glance, but its unique properties set it apart. Unlike standard glass, which consists of multiple components (such as quartz sand, borax, barium carbonate, limestone, feldspar, and soda), quartz is composed solely of SiO₂. This gives it a simple network structure formed by tetrahedral units of silicon dioxide.

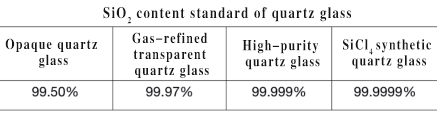

The Significance of High-Purity Quartz

High-purity quartz, often referred to as the "crown jewel" of glass materials, offers exceptional properties due to its minimal metallic impurities. This remarkable material is essential in various semiconductor processes, boasting advantages such as:

1. High Temperature Resistance: With a softening point of approximately 1730°C, quartz can withstand long-term use at 1150°C and handle short bursts up to 1450°C.

2. Chemical Corrosion Resistance: High-purity quartz exhibits minimal reactivity with most acids (except hydrofluoric acid) and demonstrates superior stability against chemical attack, being 30 times more acid-resistant than ceramics and 150 times more resistant than stainless steel.

3. Thermal Stability: High-purity quartz has an extremely low thermal expansion coefficient, allowing it to endure rapid temperature changes without fracturing.

4. Optical Clarity: This material maintains high transmittance across a wide spectrum, with visible light transmission exceeding 93% and ultraviolet transmittance reaching above 80%.

5. Electrical Insulation: High-purity quartz offers exceptional electrical resistance, making it an excellent insulator even at elevated temperatures.

Applications in the Semiconductor Industry

Due to these outstanding physical and chemical properties, high-purity quartz is extensively used in modern electronics, telecommunications, and the semiconductor industry. The growing demand for silicon wafers has significantly increased the need for quartz components, particularly in chip manufacturing.

Key Applications of Quartz in Semiconductor Manufacturing:

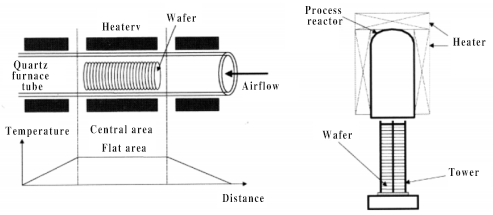

1. High-Temperature Devices:

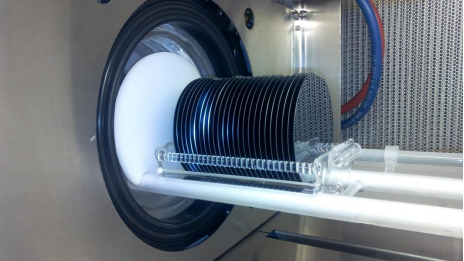

·Quartz Furnace Tubes: Essential for processes like diffusion, oxidation, and annealing, these tubes ensure high-temperature stability and efficiency during semiconductor fabrication.

·Quartz Boats: Used for transporting and processing silicon wafers, quartz boats facilitate batch manufacturing in diffusion processes.

2. Low-Temperature Devices:

·Quartz Rings: Integral to the etching process, quartz rings prevent contamination and ensure precise manufacturing during lithography and patterning.

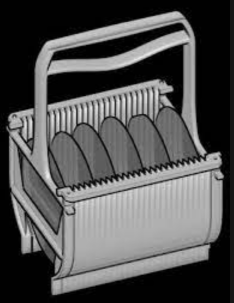

·Quartz Cleaning Baskets and Tanks: These components are crucial for cleaning silicon wafers. They must resist acid and alkali while minimizing contact area to enhance cleaning efficiency.

Conclusion

While quartz components may appear as minor consumables in the semiconductor manufacturing process, they play a crucial role in ensuring the quality and reliability of semiconductor devices. According to Techcet, high-purity quartz glass materials account for about 90% of the annual global production in the electronic information industry.

At Semicera, we are dedicated to advancing the semiconductor industry by providing high-performance quartz materials. Just as nails are essential for structural integrity, so too is quartz for semiconductor manufacturing.

2. Low-Temperature Devices:

·Quartz Rings: Integral to the etching process, quartz rings prevent contamination and ensure precise manufacturing during lithography and patterning.

·Quartz Cleaning Baskets and Tanks: These components are crucial for cleaning silicon wafers. They must resist acid and alkali while minimizing contact area to enhance cleaning efficiency.

Conclusion

While quartz components may appear as minor consumables in the semiconductor manufacturing process, they play a crucial role in ensuring the quality and reliability of semiconductor devices. According to Techcet, high-purity quartz glass materials account for about 90% of the annual global production in the electronic information industry.

At Semicera, we are dedicated to advancing the semiconductor industry by providing high-performance quartz materials. Just as nails are essential for structural integrity, so too is quartz for semiconductor manufacturing.