Ceramic Vacuum Chuck: Precision Workholding Solution for Semiconductor Wafer Manufacturing

Product Overview

Semicera Ceramic Vacuum Chuck is designed with high-performance porous ceramic materials, ideal for semiconductor wafer production, including silicon, sapphire, and gallium arsenide wafers. By utilizing a unique porous structure and vacuum adsorption principle, this chuck securely holds your workpieces, ensuring smooth, safe, and damage-free handling during various semiconductor processing stages.

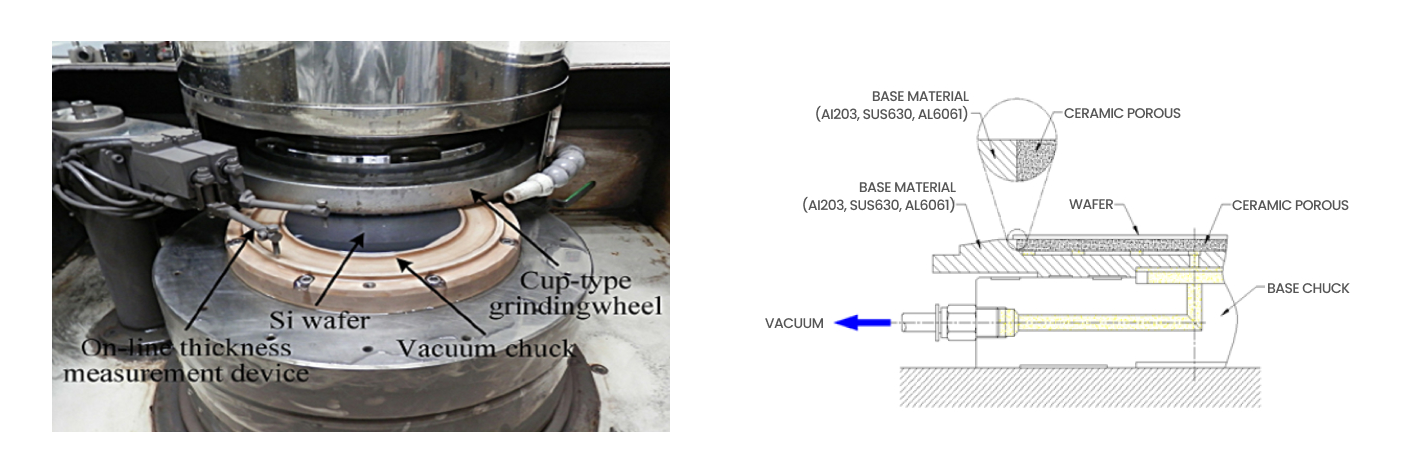

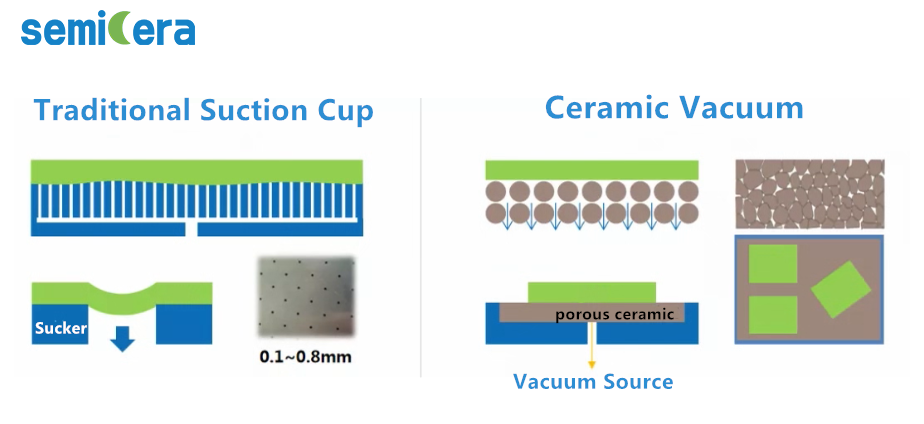

The Ceramic Vacuum Chuck works through a precisely engineered air channel system within the base. When negative pressure is applied, the chuck evenly and securely holds the workpiece, preventing any surface damage such as scratches or dents. Its specialized porous structure allows for uniform distribution of vacuum pressure, making it especially effective for delicate semiconductor wafers.

- Precision Holding and Uniform Distribution: The advanced porous ceramic structure ensures that the vacuum pressure is evenly distributed, preventing any surface damage to the wafer.

- High Strength and Wear Resistance: The ceramic material is extremely durable and resistant to wear, ensuring the chuck remains in optimal condition, even after prolonged use. This minimizes deformation or damage during processing.

- Superior Insulation Properties: The chuck provides excellent electrical insulation, reducing the risk of static interference, which is crucial for electronic components.

- Reusable and Easy to Maintain: The ceramic chuck can be easily reconditioned and used multiple times, offering long-term cost efficiency with minimal maintenance required.

- High Chemical Stability: The chuck is highly resistant to corrosive environments, making it suitable for a wide range of applications that involve chemically reactive materials.

Compared to traditional metal chucks, the Ceramic Vacuum Chuck offers superior uniform vacuum pressure, better wear resistance, and static elimination. It is especially well-suited for thin, delicate workpieces, preventing deformation or damage that can occur with metal chucks.

Wide Applications

The Ceramic Vacuum Chuck plays a crucial role in semiconductor wafer production, including thinning, cutting, grinding, cleaning, and handling processes. Its excellent vacuum holding capability and smooth operation ensure high precision and high-quality results throughout semiconductor processing.

Conclusion

Opting for a Ceramic Vacuum Chuck means choosing a high-efficiency, stable, and durable solution that enhances the quality of semiconductor wafer processing. Boost your production efficiency and ensure top-quality results. Contact our specialists today to discuss tailored solutions for your specific needs.