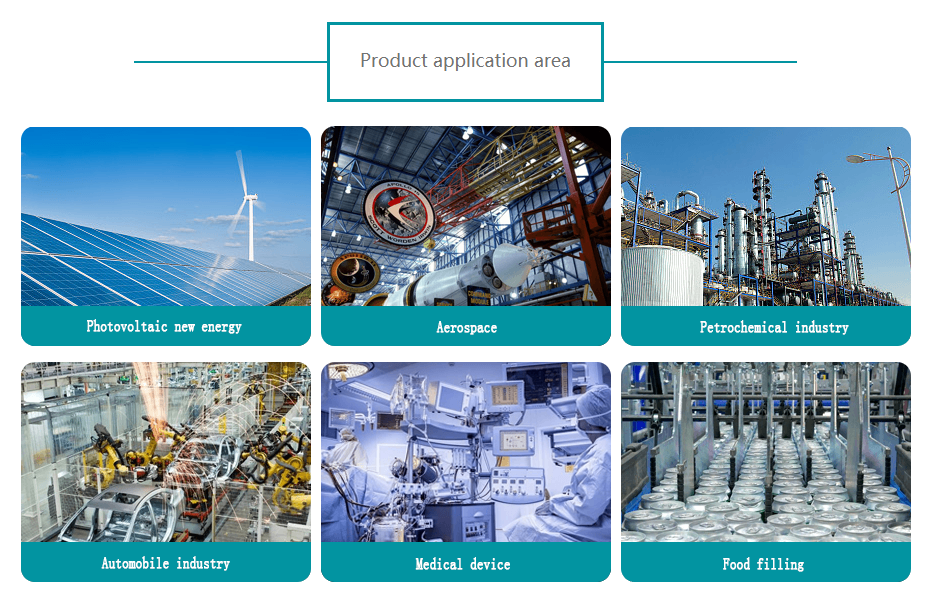

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for OEM/ODM Factory Kiln Furniture Silicon Carbide Beam / Sic Tube for Hollow Support, “Passion, Honesty, Sound assistance, Keen cooperation and Development” are our targets. We are here anticipating mates all around the environment!

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for China Silicon Carbide Beam and Kiln Furniture, By integrating manufacturing with foreign trade sectors, we can give total customer solutions by guaranteeing the delivery of right products and solutions to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified goods and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

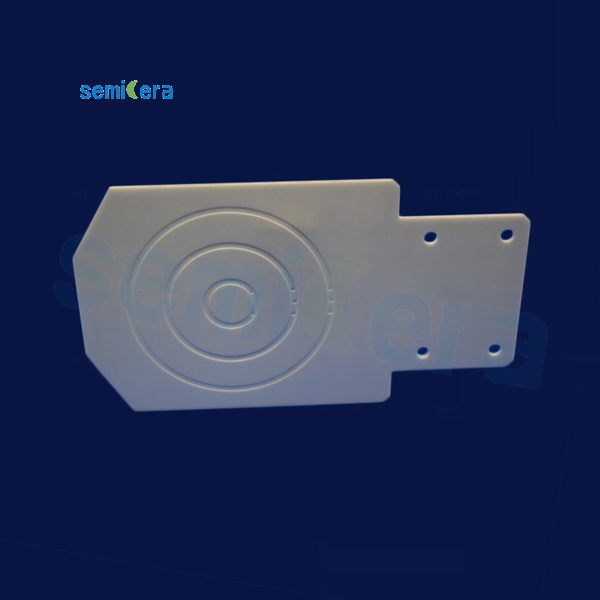

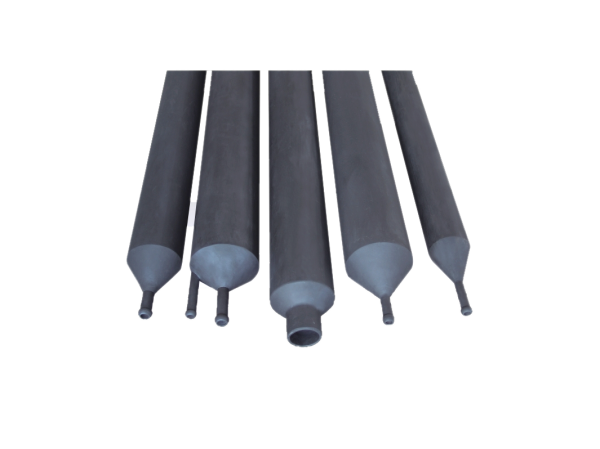

We can provide stable and reliable silicon carbide crystal boats, silicon carbide paddles, silicon carbide furnace tubes for the 4 inch to 6 inch semiconductor wafer industry. The purity can reach 99.9% without polluting the wafer.

Silicon carbide furnace tube is mainly used for: 4-6 inch silicon wafer LTO= silica, SIPOS= oxy-polysilicon, SI3N4= silicon nitride, PSG= phosphosilicon glass, POLY= polysilicon film growth. It is the raw material gas (or liquid source gasification) activated by thermal energy to generate a solid film on the surface of the substrate. Low pressure chemical vapor deposition is carried out at low pressure, due to the low pressure, the average free path of gas molecules is large, so that the uniformity of the grown film is good, and the substrate can be vertically placed and the amount of loading is large, especially suitable for large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and optical fiber and other industries of industrial production special equipment.

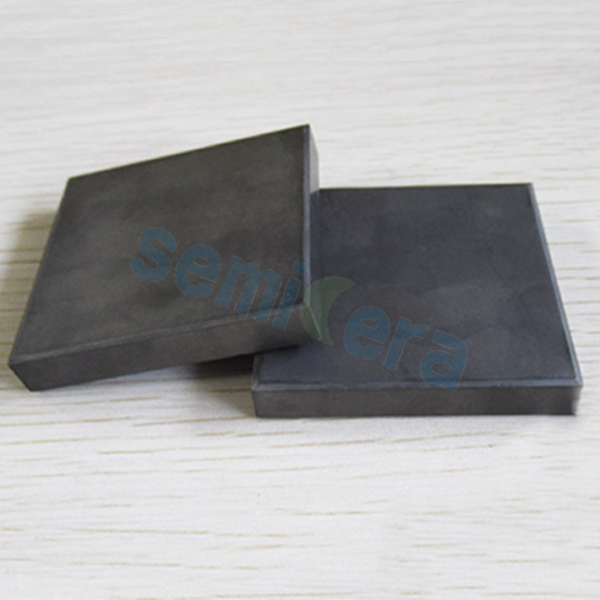

Semicera Energy Technology Co., Ltd is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process, grouting molding process and vacuum extrusion molding process. Our company uses 6 silicon carbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can also provide you with silicon carbide ceramic sintered products, but also can provide silicon carbide ceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for OEM/ODM Factory Kiln Furniture Silicon Carbide Beam / Sic Tube for Hollow Support, “Passion, Honesty, Sound assistance, Keen cooperation and Development” are our targets. We are here anticipating mates all around the environment!

OEM/ODM Factory China Silicon Carbide Beam and Kiln Furniture, By integrating manufacturing with foreign trade sectors, we can give total customer solutions by guaranteeing the delivery of right products and solutions to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified goods and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.