Which has a complete scientific excellent management technique, excellent quality and very good religion, we earn good name and occupied this field for OEM/ODM China Diamond Silicon Carbide Black Corundum Stone Price for Casting Industry Steelmaking Abrasive, We imagine we are going to become a leader in developing and producing high-quality products and solutions in both Chinese and international markets. We hope to cooperate with more friends for mutual advantages.

Which has a complete scientific excellent management technique, excellent quality and very good religion, we earn good name and occupied this field for China Bowl Type Grinding Stone and Bowl Size White Bowl Type Grinding Stone, Our tenet is “integrity first, quality best”. We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Description

Silicon carbide grinding drum adopts isostatic pressing molding process, density 3.09g/cm3, maximum φ950mm, Vickers hardness 2550HV.

silicon carbide ceramic grinding barrel in the application of energy and environmental protection The sensible heat of the gas in the heat exchanger of silicon carbide ceramic grinding barrel can be used to purify the gas directly at high temperature. Compared with normal temperature purification, the thermal efficiency has been greatly improved. The direct application of high temperature purified gas to gas turbine power generation can greatly improve the efficiency of power supply, reduce the emission of harmful substances and save water.

![]()

![]()

Silicon carbide grinding barrel advantage

(1) High temperature resistance, small coefficient of thermal expansion

Silicon carbide is made at high temperatures. In some high temperature environment, the material is required to have a certain processing strength, and meet the processing accuracy, and silicon carbide ceramics can achieve these two points. The highest use temperature of silicon carbide is about 800℃, and the bearing temperature of steel is only 250℃. By rough calculation, the average thermal expansion coefficient of SIC is 4.4×10-6/ C in the range of 25~1400℃. The thermal expansion coefficient of SIC is much smaller than that of other abrasives and high temperature materials. For example, the coefficient of thermal expansion of corundum can be as high as (7~8)× 10-6/℃.

(2) High thermal conductivity

The high thermal conductivity of SIC is another important characteristic of its physical properties. The thermal conductivity of silicon carbide is much higher than that of other refractory materials and abrasives, about 4 times that of corundum. Silicon carbide thermal expansion coefficient is low, high thermal conductivity, making its products in the process of heating and cooling under less thermal stress, which is also silicon carbide products thermal shock resistance is particularly good reason.

(3) Corrosion resistance

Silicon carbide because of its melting point (decomposition temperature), chemical inertia and thermal shock resistance is high, can be used for a variety of silicon carbide ceramic products, such as ceramic products furnace grinding tools, ceiling plate and sagger, zinc smelting industrial vertical cylinder distillation furnace with silicon carbide brick, aluminum electrolytic cell lining, crucible, small furnace material.

![]()

![]()

Corrosion resistance application

1, sliding parts (mechanical seal, chemical pump bearing, shaft)

2, crusher accessories (classifier, air mill, sand mill)

3.Semiconductor manufacturing equipment parts (XY platform, MOCVD tray, focusing ring, wafer chuck)

4. Parts of molding machine (parts of camera lens molding machine)

5 heat resistant parts (burner nozzle, high temperature testing machine parts, molten metal crucible)

6. Wear-resistant parts (sand blasting machine nozzle, shot blasting machine polishing machine blade, buried pipeline protection plate, fishing tackle guide ring)

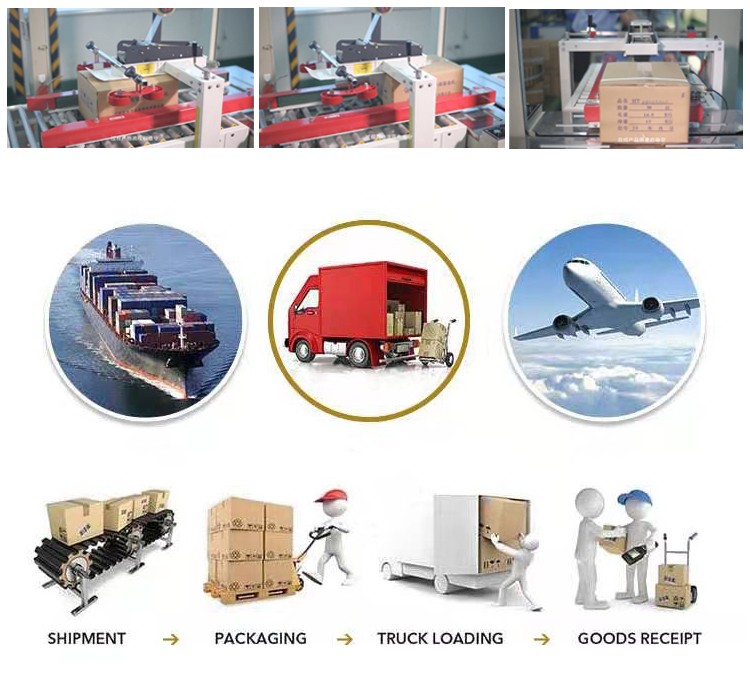

Transport

Why you can choose Wei Tai ?

1) we have sufficient stock guarantee.

2) professional packaging ensures product integrity. The product will be delivered to you safely.

3) more logistics channels enable products to be delivered to you.

FAQ

Q: Are you trading company or manufacturer?

A:We are an more than 10 vears factory with iso9001 certificacted

Q:How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock,or 10-15 days if the goods are not in stock, it is according to your quantity.

Q: How can Iget the sample to check your quality?

A: After price confirmation, you can require for samples to check our product’s quality. If you just need a blank sample to check the design and quality,we will provide you sample for free as long as you afford the express freight.

Q:What is your terms of payment?

A: We accept payment by Western union,Pavpal,Alibaba,T/TL/Cetc..for bulk order,we do 30% deposit balance before shipment.

Which has a complete scientific excellent management technique, excellent quality and very good religion, we earn good name and occupied this field for OEM/ODM China Diamond Silicon Carbide Black Corundum Stone Price for Casting Industry Steelmaking Abrasive, We imagine we are going to become a leader in developing and producing high-quality products and solutions in both Chinese and international markets. We hope to cooperate with more friends for mutual advantages.

OEM/ODM China China Bowl Type Grinding Stone and Bowl Size White Bowl Type Grinding Stone, Our tenet is “integrity first, quality best”. We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

-

Europe style for U Type Sic Heating Element, Si...

-

OEM Customized Good Erosion Resistance Magnesiu...

-

Factory Supply Ceramic Setter Plate for Kiln Fu...

-

Wholesale Dealers of Silicon Sic Carbide Thermo...

-

Special Price for Super Silicon Carbide (SiC) H...

-

Hot Selling for Customizable Sic Paddles with D...