We’re experienced manufacturer. Wining the majority in the crucial certifications of its market for OEM Factory for Black Sic Silicon Carbide Crucibles for Melting, We will wholeheartedly welcome all clients in the industry both at home and abroad to cooperate hand in hand, and create a bright future together.

We’re experienced manufacturer. Wining the majority in the crucial certifications of its market for China Silicon Carbide Ceramic Crucible and Sic Crucible, For anyone who is keen on any of our merchandise right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it’s easy, you may locate out our address in our web-site and come to our business for far more information of our goods by your self. We’re always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Graphite crucible is mainly used to smelt copper, brass, gold, silver, zinc and lead, and other non-ferrous metals and their alloys.

Our graphite crucible are processed with high purity isostatic pressed graphite, which has good thermal conductivity and high temperature resistance. In the process of high temperature use, the coefficient of thermal expansion is small, and it has certain strain resistance to acute heat and acute cooling. It has strong corrosion resistance to acid and alkaline solution and excellent chemical stability. The specific models can be customized with drawings and samples, and the materials are domestic graphite and imported graphite to meet the different needs of customers.

The main raw materials of graphite crucible are graphite, silicon carbide, silica, refractory clay, pitch, and tar, etc.

>High Pure Graphite Crucible

>Isostatic Graphite Crucible

>Silicon Carbide Graphite Crucible

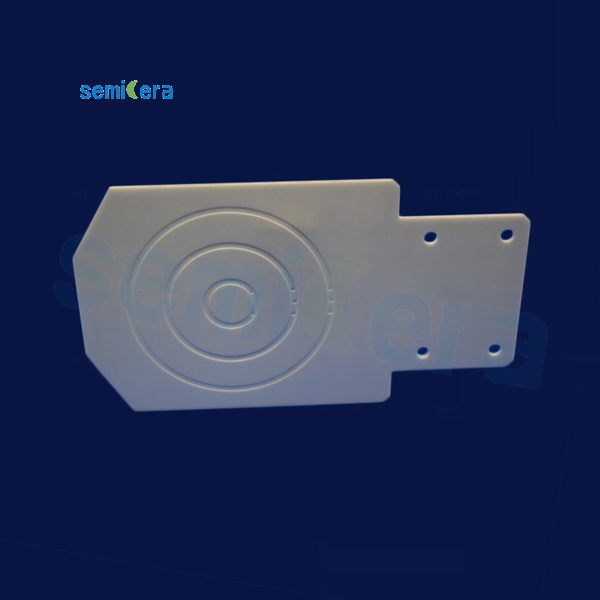

>Silicon Carbide Crucible

>Clay Graphite Crucible

>Quarts Crucible

Features:

1. Long working life time

2. High thermal conductivity

3. New-style materials

4. Resistance to corrosion

5. Resistance to oxidation

6. High-strength

7. Multi-function

|

Technical Data of Material |

|||

|

Index |

Unit |

Standard value |

Test value |

|

Temperature Resistance |

℃ |

1650℃ |

1800℃ |

|

Chemical Composition |

C |

35~45 |

45 |

|

SiC |

15~25 |

25 |

|

|

AL2O3 |

10~20 |

25 |

|

|

SiO2 |

20~25 |

5 |

|

|

Apparent Porosity |

% |

≤30% |

≤28% |

|

Compressive Strength |

Mpa |

≥8.5MPa |

≥8.5MPa |

|

Bulk Density |

g/cm3 |

≥1.75 |

1.78 |

|

Our silicon carbide crucible is isostatic forming, which can use 23 times in furnace, while others only can use 12 times |

|||

We’re experienced manufacturer. Wining the majority in the crucial certifications of its market for OEM Factory for Black Sic Silicon Carbide Crucibles for Melting, We will wholeheartedly welcome all clients in the industry both at home and abroad to cooperate hand in hand, and create a bright future together.

OEM Factory for China Silicon Carbide Ceramic Crucible and Sic Crucible, For anyone who is keen on any of our merchandise right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it’s easy, you may locate out our address in our web-site and come to our business for far more information of our goods by your self. We’re always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

-

New Fashion Design for Thermal Sintering High S...

-

China Supplier Dual Air Inlet Venturi Silicon C...

-

One of Hottest for 1t High Temperature Resistan...

-

Massive Selection for Carbon Roller Rigid Felts...

-

Factory For Factory Price Custom Industrial Cer...

-

China New Product Best Quality Silicon Carbide ...