-

Exploring semiconductor silicon carbide epitaxial disks: Performance advantages and application prospects

In today's field of electronic technology, semiconductor materials play a crucial role. Among them, silicon carbide (SiC) as a wide band gap semiconductor material, with its excellent performance advantages, such as high breakdown electric field, high saturation speed, h...Read more -

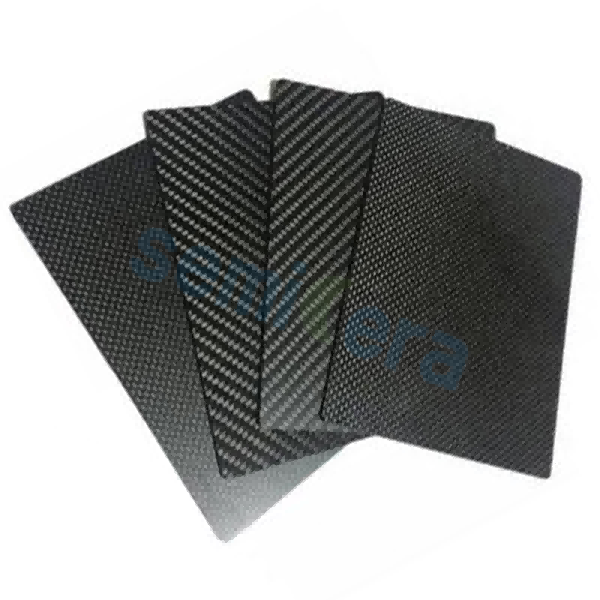

Graphite hard felt – innovative material, open a new era of science and technology

As a new material graphite hard felt, the manufacturing process is quite unique. During the mixing and felting process, graphene fibers and glass fibers interact to form a new material that retains both the high electrical conductivity and high strength of graphene and ...Read more -

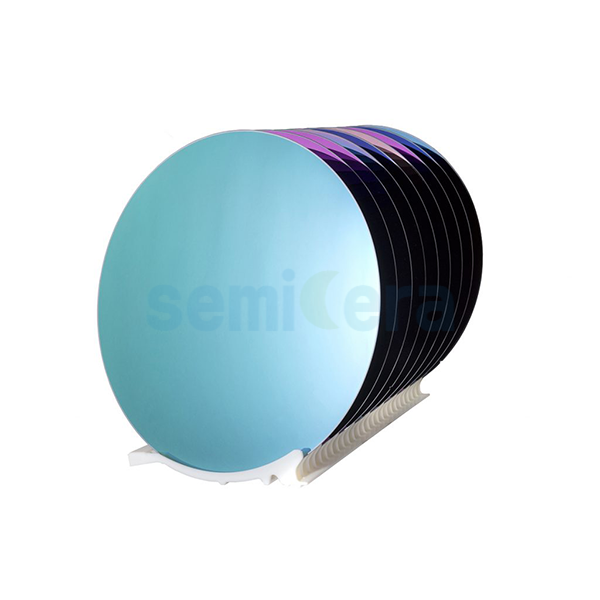

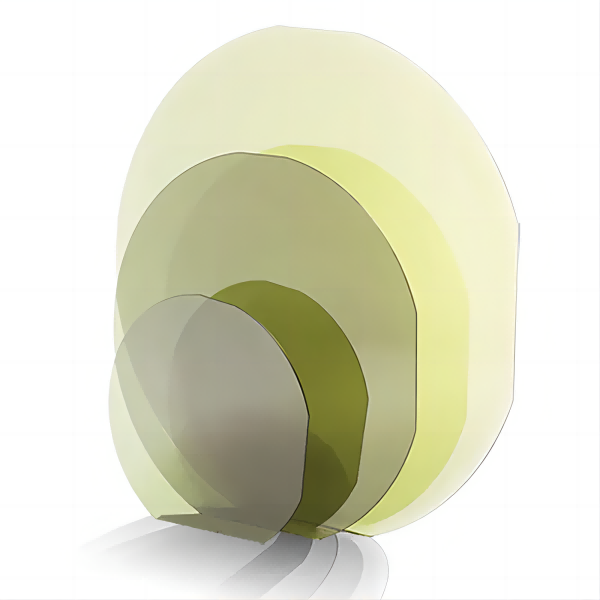

What is semiconductor silicon carbide (SiC) wafer

Semiconductor silicon carbide (SiC) wafers, this new material has gradually emerged in recent years, with its unique physical and chemical properties, injected a new vitality for the semiconductor industry. SiC wafers, using monocrystals as raw materials, are carefully g...Read more -

Silicon carbide wafer production process

Silicon carbide wafer is made of high purity silicon powder and high purity carbon powder as raw materials, and silicon carbide crystal is grown by physical vapor transfer method (PVT), and processed into silicon carbide wafer. 1.Raw material synthesis: High purity sili...Read more -

Silicon carbide History and Silicon Carbide Coating Application

The Development and Applications of Silicon Carbide (SiC) 1. A Century of Innovation in SiCThe journey of silicon carbide (SiC) began in 1893, when Edward Goodrich Acheson designed the Acheson furnace, using carbon materials to achieve the industrial production of SiC th...Read more -

Silicon carbide coatings: New breakthroughs in materials science

With the development of science and technology, the new material silicon carbide coating is gradually changing our lives. This coating, which is prepared on the surface of parts by physical or chemical vapor deposition, spraying and other methods, has attracted great att...Read more -

SiC Coated Graphite Barrel

As one of the core components of MOCVD equipment, graphite base is the carrier and heating body of the substrate, which directly determines the uniformity and purity of the film material, so its quality directly affects the preparation of the epitaxial sheet, and at the ...Read more -

Method for preparing silicon carbide coating

At present, the preparation methods of SiC coating mainly include gel-sol method, embedding method, brush coating method, plasma spraying method, chemical gas reaction method (CVR) and chemical vapor deposition method (CVD). Embedding method: The method is a kind of hig...Read more -

Congratulations to our( Semicera), partner, SAN ‘an Optoelectronics, on the rise in stock price

Oct. 24 -- Shares in San’an Optoelectronics climbed as much as 3.8 today after the Chinese semiconductor manufacturer said that its silicon carbide factory, which will supply the firm’s auto chip joint venture with Swiss tech giant ST Microelectronics once it is finished...Read more -

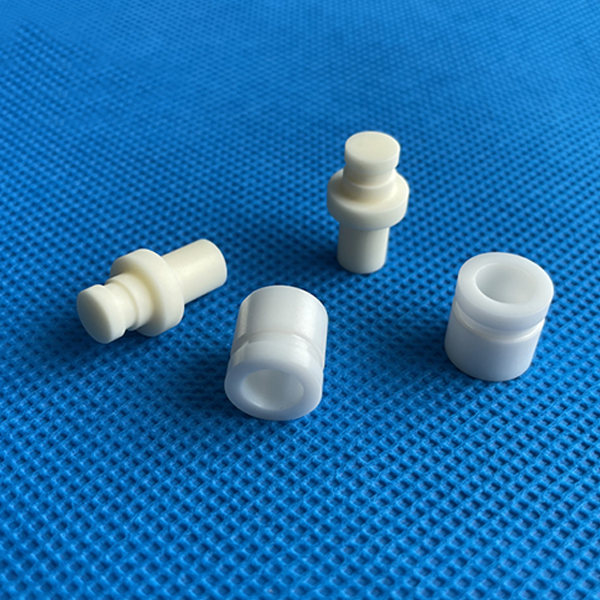

Precautions for the use of alumina ceramic structural parts

In recent years, alumina ceramics have been widely used in high-end fields such as instrumentation, food medical treatment, solar photovoltaic, mechanical and electrical appliances, laser semiconductor, petroleum machinery, automotive military industry, aerospace and oth...Read more -

Material structure and properties of sintered silicon carbide under atmospheric pressure

【 Summary description 】 In modern C, N, B and other non-oxide high-tech refractory raw materials, atmospheric pressure sintered silicon carbide is extensive and economical, and can be said to be emery or refractory sand. Pure silicon carbide is colorless transparent cr...Read more -

Manufacturing method for transporting device of silicon carbide furnace tube

Silicon carbide furnace tube has high temperature, wear resistance, corrosion resistance, high hardness, high strength, high thermal conductivity, high cold and hot sudden change performance, good oxidation resistance and other excellent properties, in a variety of heat ...Read more