Since crucible is used as container and there is convection inside, as the size of generated single crystal increases, heat convection and temperature gradient uniformity become more difficult to control. By adding magnetic field to make the conductive melt act on Lorentz force, convection can be slowed down or even eliminated to produce high-quality single crystal silicon.

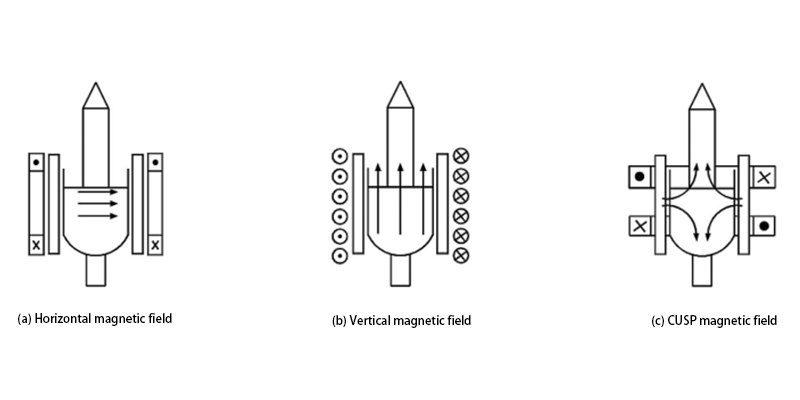

According to the type of magnetic field, it can be divided into horizontal magnetic field, vertical magnetic field and CUSP magnetic field:

Vertical magnetic field cannot eliminate the main convection due to structural reasons and is rarely used.

The direction of the magnetic field component of the horizontal magnetic field is perpendicular to the main heat convection and partial forced convection of the crucible wall, which can effectively inhibit movement, maintain the flatness of the growth interface, and reduce growth stripes.

CUSP magnetic field has more uniform flow and heat transfer of melt due to its symmetry, so the research on vertical and CUSP magnetic fields has been going hand in hand.

In China, Xi’an University of Technology has realized the production and crystal pulling experiments of silicon single crystals using magnetic fields earlier. Its main products are 6-8in popular types, which are aimed at the silicon wafer market for solar photovoltaic cells. In foreign countries, such as KAYEX in the United States and CGS in Germany, their main products are 8-16in, which are suitable for single crystal silicon rods at the level of ultra-large-scale integrated circuits and semiconductors. They have a monopoly in the field of magnetic fields for the growth of large-diameter high-quality single crystals and are the most representative.

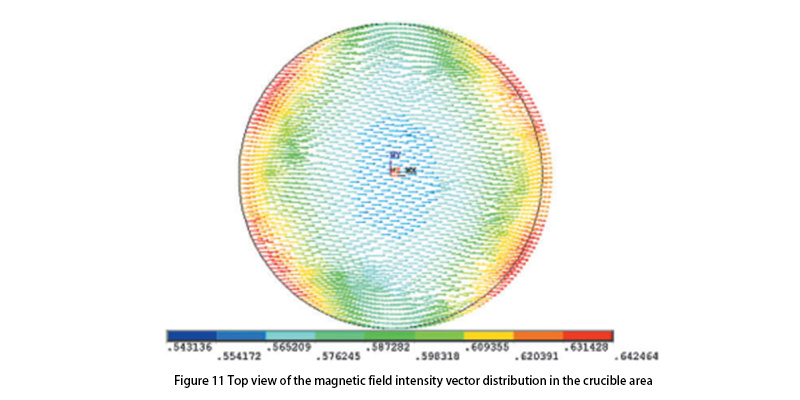

The magnetic field distribution in the crucible area of the single crystal growth system is the most critical part of the magnet, including the strength and uniformity of the magnetic field at the edge of the crucible, the center of the crucible, and the appropriate distance below the liquid surface. The overall horizontal and uniform transverse magnetic field, the magnetic lines of force are perpendicular to the crystal growth axis. According to the magnetic effect and Ampere’s law, the coil is closest to the edge of the crucible and the field strength is the largest. As the distance increases, the air magnetic resistance increases, the field strength gradually decreases, and it is the smallest at the center.

The role of superconducting magnetic field

Inhibiting thermal convection: In the absence of an external magnetic field, molten silicon will produce natural convection during heating, which may lead to uneven distribution of impurities and the formation of crystal defects. The external magnetic field can suppress this convection, making the temperature distribution inside the melt more uniform and reducing the uneven distribution of impurities.

Controlling the crystal growth rate: The magnetic field can affect the rate and direction of crystal growth. By precisely controlling the strength and distribution of the magnetic field, the crystal growth process can be optimized and the integrity and uniformity of the crystal can be improved. During the growth of single crystal silicon, oxygen enters the silicon melt mainly through the relative movement of the melt and the crucible. The magnetic field reduces the chance of oxygen contacting the silicon melt by reducing the convection of the melt, thereby reducing the dissolution of oxygen. In some cases, the external magnetic field can change the thermodynamic conditions of the melt, such as by changing the surface tension of the melt, which may help the volatilization of oxygen, thereby reducing the oxygen content in the melt.

Reduce the dissolution of oxygen and other impurities: Oxygen is one of the common impurities in the growth of silicon crystals, which will cause the quality of the crystal to deteriorate. The magnetic field can reduce the oxygen content in the melt, thereby reducing the dissolution of oxygen in the crystal and improving the purity of the crystal.

Improve the internal structure of the crystal: The magnetic field can affect the defect structure inside the crystal, such as dislocations and grain boundaries. By reducing the number of these defects and affecting their distribution, the overall quality of the crystal can be improved.

Improving the electrical properties of crystals: Since magnetic fields have a significant effect on the microstructure during crystal growth, they can improve the electrical properties of crystals, such as resistivity and carrier lifetime, which are crucial for manufacturing high-performance semiconductor devices.

Welcome any customers from all over the world to visit us for a further discussion!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Post time: Jul-24-2024