Many industrial production occasions will be used in alumina ceramic parts, which fully shows that ceramic parts compared with other materials have a lot of superior performance, will be popular in the industry. How can such good ceramic pieces be produced?

At present, alumina ceramics can be mainly used for temperature measuring instrument thermocouple thermometer protective tube, insulation tube; At the same time, it can also be used in the furnace tube of industrial resistance furnace, experimental furnace and heat treatment furnace. In addition, steel chemical analysis of carbon tube and sulfur tube, as well as other high temperature resistance, acid and alkali corrosion resistance insulation instrument components are to use ceramic porcelain parts as the foundation.

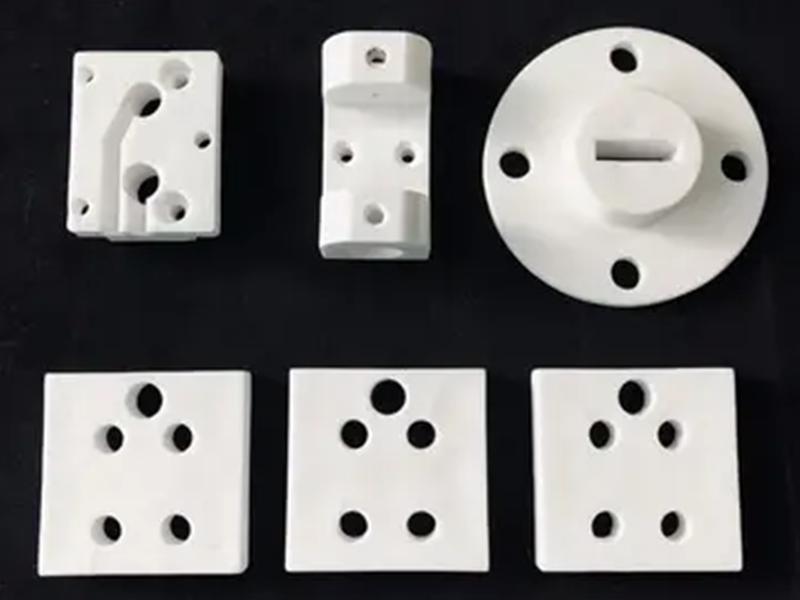

Alumina ceramic heating sleeve

It seems that alumina ceramics use its strong mechanical strength, thermal impact resistance; Good thermal conductivity and insulation; As well as higher softening temperature advantages, in many industries are used in handy, significant.

The production process of alumina ceramics is generally divided into three main steps, in order to ensure its quality must be done in each link, the first is the preparation of ceramic powder as a raw material. If the manufacture of universal ceramic porcelain parts, there are ready to spray dried good granulation powder on the market; If you need to control the ingredients yourself, you will need to purchase a ball mill and ball as well as a spray dryer.

After you have the raw material, you can begin to press molding. For flake products less than 2 mm, you can consider using the gelatinized type method; And for more than 2 mm of ceramic porcelain parts can be considered to use the method of pressing molding.

Followed by sintering and processing, if large quantities of sintered alumina ceramics can be used for continuous production of tunnel kiln; The processing is mainly determined according to the complexity of the product. Some ceramics do not need to be processed and can be sold directly by opening molding.

Post time: Jun-05-2023