Tantalum carbide (TaC) is a binary compound of tantalum and carbon with the chemical formula TaC x, where x usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metallic conductivity. They are brown-grey powders and are usually processed by sintering.

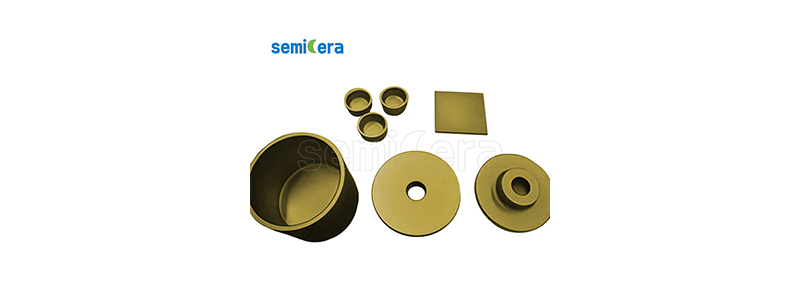

Tantalum carbide is an important metal ceramic material. One very important use of tantalum carbide is tantalum carbide coating.

Product characteristics of tantalum carbide coating

High melting point: The melting point of tantalum carbide is as high as 3880°C, which makes it stable in high temperature environments and not easy to melt or degrade.

Working condition : In general, the normal Working condition of Tantalum carbide (TaC) is 2200°C. Considering its extremely high melting point, TaC is designed to withstand such high temperatures without losing its structural integrity.

Hardness and wear resistance: It has extremely high hardness (Mohs hardness is about 9-10) and can effectively resist wear and scratches.

Chemical stability: It has good chemical stability to most acids and alkalis and can resist corrosion and chemical reactions.

Thermal conductivity: Good thermal conductivity enables it to effectively disperse and conduct heat, reducing the impact of heat accumulation on the material.

Application scenarios and advantages in the semiconductor industry

MOCVD equipment: In MOCVD (chemical vapor deposition) equipment, tantalum carbide coatings are used to protect the reaction chamber and other high-temperature components, reduce the erosion of the equipment by deposits, and extend the service life of the equipment.

Advantages: Improve the high-temperature resistance of the equipment, reduce maintenance frequency and costs, and improve production efficiency.

Wafer processing: Used in wafer processing and transmission systems, tantalum carbide coatings can enhance the wear resistance and corrosion resistance of the equipment.

Advantages: Reduce product quality problems caused by wear or corrosion, and ensure the stability and consistency of wafer processing.

Semiconductor process tools: In semiconductor process tools, such as ion implanters and etchers, tantalum carbide coatings can improve the durability of tools.

Advantages: Extend the service life of tools, reduce downtime and replacement costs, and improve production efficiency.

High temperature areas: In electronic components and devices in high temperature environments, tantalum carbide coatings are used to protect materials from high temperatures.

Advantages: Ensure the stability and reliability of electronic components under extreme temperature conditions.

Future Development Trends

Material Improvement: With the development of material science, the formulation and deposition technology of tantalum carbide coatings will continue to improve to improve its performance and reduce costs. For example, more durable and low-cost coating materials may be developed.

Deposition Technology: It will be possible to have more efficient and precise deposition technologies, such as improved PVD and CVD technologies, to optimize the quality and performance of tantalum carbide coatings.

New Application Areas: The application areas of tantalum carbide coatings will expand to more high-tech and industrial fields, such as aerospace, energy and automotive industries, to meet the demand for high-performance materials.

Post time: Aug-08-2024