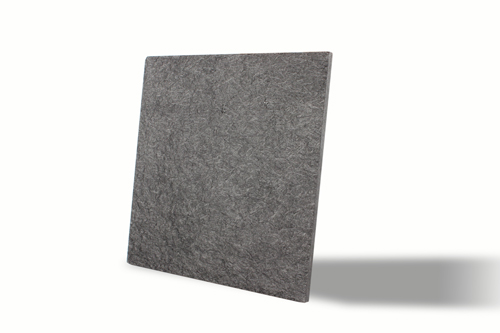

Silicon carbide wear-resistant coating is a kind of polymer and corundum, silicon carbide and other composite ultrafine powder filler and chemical additives made of two-component wear-resistant particle adhesive data, in the development and production of continuous innovation, participate in a high-efficiency accelerator, so that epoxy can be modified, the bonding strength is greatly improved, curing speed is accelerated, silicon carbide coating to promote the thickening of mud, can be applied in Non-flowing, non-polluting silicon carbide coating on vertical working surface.

Mainly used in various thermal power plants coarse and fine powder separator exhaust fan impeller, primary coal blanking air pipe, silicon carbide coated ball mill inlet and outlet pipe and other equipment large area wear resistant parts of the wear tree, can also be used for various chemical equipment anti-corrosion surface layer and lining wear resistant anti-corrosion coating silicon carbide coating.

When the mastic is coated on the equipment substrate, the high molecular polymer in the mastic forms a strong molecular bonding bond with the equipment substrate, so that the mastic and the equipment coating surface solidify into one. Silicon carbide coating corundum, silicon carbide and other composite powder and ultrafine powder fillers give the equipment to be coated with special properties, that is, high wear resistance while the polymer itself has anti-corrosion properties, so that the equipment after painting has a wear and anti-corrosion effect of silicon carbide coating.

Post time: Jul-18-2023