In the field of semiconductor manufacturing, MOCVD (Metal Organic Chemical Vapor Deposition) technology is rapidly becoming a key process, with the MOCVD Wafer Carrier being one of its core components. The advancements in MOCVD Wafer Carrier are not only reflected in its manufacturing process but also in its wide range of application scenarios and future development potential.

Advanced Process

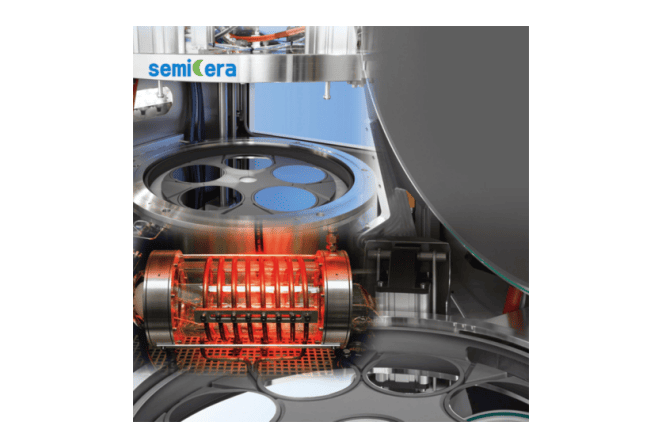

The MOCVD Wafer Carrier utilizes high-purity graphite material, which, through precision processing and CVD (Chemical Vapor Deposition) SiC coating technology, ensures optimal performance of wafers in MOCVD reactors. This high-purity graphite material boasts excellent thermal uniformity and rapid temperature cycling capabilities, enabling higher yields and longer service life in the MOCVD process. Additionally, the design of the MOCVD Wafer Carrier takes into account the needs for temperature uniformity and rapid heating and cooling, thereby improving the stability and efficiency of the process.

Application Scenarios

The MOCVD Wafer Carrier is widely used in fields such as LED, power electronics, and lasers. In these applications, the performance of the wafer carrier directly affects the quality of the final product. For instance, in LED chip production, the rotation and uniform heating of the MOCVD Wafer Carrier ensure the quality of the coating, thereby reducing the scrap rate of the chips. Furthermore, the MOCVD Wafer Carrier plays a crucial role in the manufacture of power electronics and lasers, ensuring the high performance and reliability of these devices.

Future Development Trends

From a global perspective, companies like AMEC, Entegris, and Shin-Etsu Chemical Co., Ltd. have leading technological advantages in the production of MOCVD Wafer Carriers. With the continuous advancement of semiconductor technology, the demand for MOCVD Wafer Carriers is also growing. In the future, with the popularization of emerging technologies such as 5G, the Internet of Things, and new energy vehicles, MOCVD Wafer Carriers will play an important role in more field.

Moreover, with advancements in materials science, new coating technologies and higher purity graphite materials will further enhance the performance of MOCVD Wafer Carriers. For example, future MOCVD Wafer Carriers may adopt more advanced coating technologies to improve their durability and thermal stability, thereby further reducing production costs and improving production efficiency.

Post time: Aug-09-2024