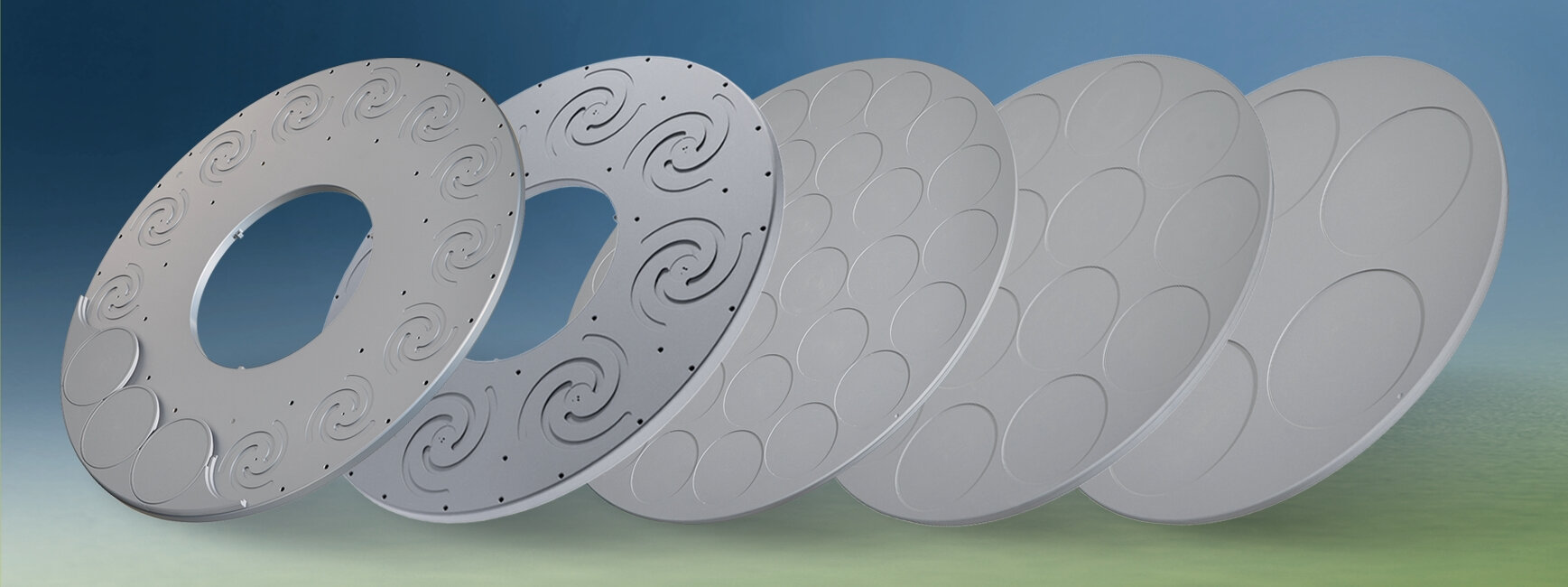

Silicon carbide trays, also known as SiC trays, are important materials used to carry silicon wafers in the semiconductor manufacturing process. Silicon carbide has excellent properties such as high hardness, high temperature resistance, and corrosion resistance, so it is gradually replacing traditional materials such as quartz and ceramic trays in the semiconductor industry. With the development of the semiconductor industry, especially in the fields of 5G, optoelectronic devices, power electronics, etc., the demand for silicon carbide trays is also increasing.

Semicera silicon carbide trays use advanced sintering processes during the manufacturing process to ensure the high density and strength of the trays, which enables them to maintain stable performance under harsh conditions such as high temperature and high pressure. At the same time, the low thermal expansion coefficient of silicon carbide trays can reduce the impact of temperature changes on the processing accuracy of silicon wafers, thereby improving the yield rate of products.

The silicon carbide trays developed by Semicera are not only suitable for the processing of traditional silicon wafers, but also can be used in the manufacture of silicon carbide wafers, which is crucial for the future development of the semiconductor industry. Silicon carbide wafers have higher electron mobility and better thermal conductivity, which can significantly improve the working efficiency and performance of devices. Therefore, the demand for silicon carbide trays suitable for their production is also rising.

With the continuous advancement of semiconductor manufacturing technology, the design and manufacturing process of silicon carbide trays are also being optimized. In the future, Semicera will continue to work on improving the performance of silicon carbide pallets to meet the market demand for high-precision, high-reliability pallets. The widespread use of silicon carbide pallets not only promotes the development of semiconductor manufacturing processes, but also provides strong support for the realization of more efficient and stable electronic products.

Post time: Aug-30-2024