Silicon carbide furnace tube has the advantages of high strength, high hardness, good wear resistance, high temperature resistance, corrosion resistance, good thermal shock resistance, high thermal conductivity, good oxidation resistance and so on. Mainly used in medium frequency casting, various heat treatment furnace, metallurgy, chemical industry, non-ferrous metal forging and other occupations. Silicon carbide furnace tube is widely used in metallurgical sintering furnace and medium frequency heating casting furnace, and its length can be customized according to the actual needs of the site.

Characteristics of silicon carbide furnace tubes

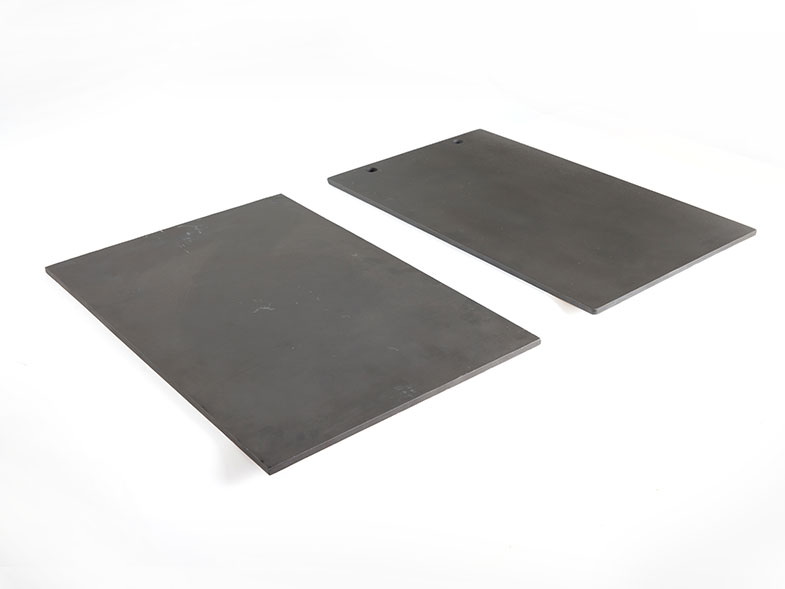

Silicon carbide furnace tube is an excellent product of silicon carbide sintered at high temperature with silicon carbide as main raw material. It has the advantages of high temperature resistance, corrosion resistance, fast thermal conductivity, high strength, high hardness, good wear resistance, good thermal shock resistance, large thermal conductivity, good oxidation resistance and so on. Both ends are equipped with special high-temperature insulation bushings, the corrosion of metal solution to electric heating elements (including silicon carbide rod, electric furnace wire, etc.) can be effectively avoided, and the indicators are better than all kinds of graphite products. The silicon carbide furnace tube has thermal conductivity, oxidation resistance, thermal shock resistance, high temperature wear resistance, good chemical stability, strong acid resistance, no reaction to strong acid and alkali.

Silicon carbide furnace tube production technology: the finished product takes silicon carbide as the primary raw material, and is an excellent silicon carbide finished product fired by special technology at high temperature. The length standard can be customized according to the actual needs of customers. The main uses of silicon carbide furnace tube: widely used in non-ferrous metal training, aluminum products degasing system, printing and dyeing machinery, zinc and aluminum training and finished product processing.

Industrial development of silicon carbide

Silicon carbide has the characteristics of high input impedance, low noise, good linearity, etc., is one of the rapidly developing silicon carbide accessories, and the first to achieve commercialization. Compared with MOSFETs, there are no reliability problems caused by gate oxide defects and low carrier mobility limitations, and its unipolar operating characteristics maintain good high-frequency operation capability. In addition, the silicon carbide junction structure has better stability and reliability at high temperatures so that the threshold voltage is usually negative, that is, the normally open device, which is extremely unfavorable for power electronics applications, and is not compatible with the current common drive circuit. By introducing the technology of groove injection device, the enhanced device under normal off state is developed. However, enhanced devices are often formed at the expense of certain positive on-resistance characteristics, so normally open (depletion type) is easier to achieve higher power density and current capacity, and depletion type can be achieved by cascading normally off operating state. The cascade method is implemented through a series of low-voltage silicon-based MOSFETs. The cascaded drive circuit is naturally compatible with the general purpose silicon device drive circuit. This cascade structure is very suitable for replacing the original silicon in high-voltage and high-power occasions, and directly avoids the compatibility problem of the drive circuit.

Post time: Sep-25-2023