Alumina ceramic manipulators play an important role in the semiconductor industry, mainly used to transfer wafers in high clean environments. Alumina ceramic material has excellent performance and is very suitable for making robots, but alumina ceramic is not only a ceramic material with extremely high hardness, it is also a very difficult to process ceramic material. Semicera Energy Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables., Among them, alumina ceramics is one of the important products of Semicera Energy. We have been working in this field for many years, and we have specially developed a new processing technology for the processing difficulties of alumina ceramics. Has been able to provide customers with qualified ceramic mechanical arm products. The following engineers from Semicera Energy will introduce what are the difficulties in precision machining alumina ceramic manipulators.

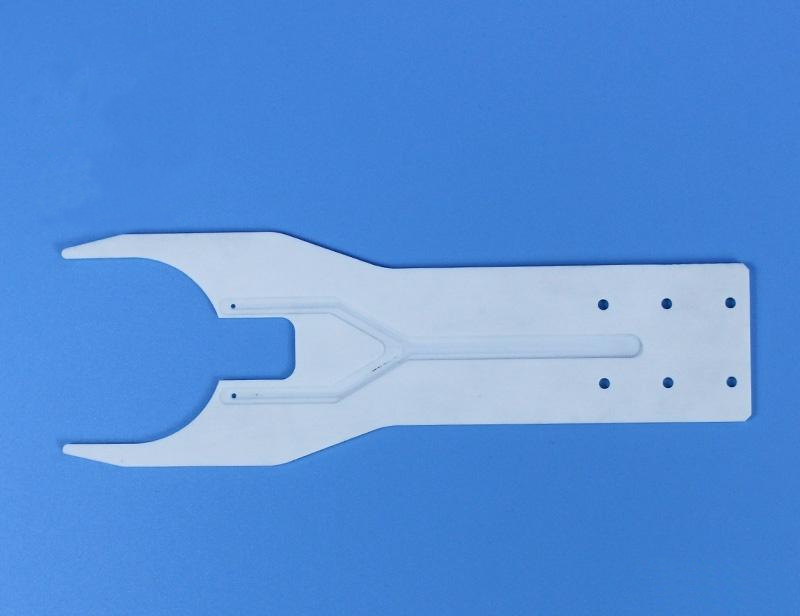

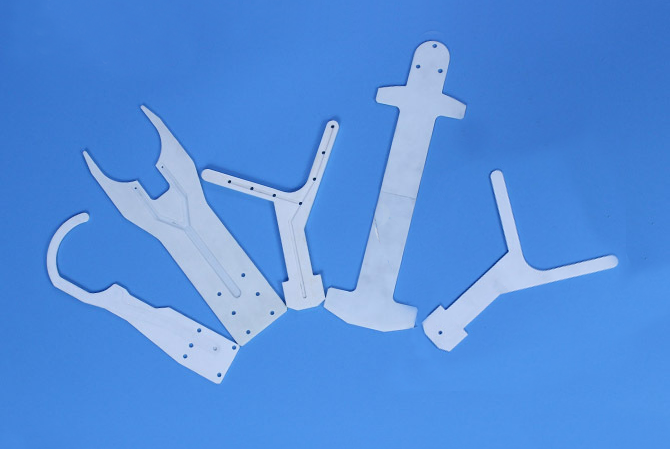

Alumina ceramic robotic arm

1. Because of the high hardness of alumina ceramics, the hardness of the general tool is far less than that of alumina ceramics, at this time we will choose a diamond tool with better hardness, even so it will accelerate the wear of the tool and increase the cost of the tool; Therefore, the cost of precision processing alumina ceramics is relatively high.

2. Alumina ceramics have good thermal stability, but the impact resistance is poor, the brittleness is large, and the edge collapse phenomenon is easy to occur in the process of processing alumina ceramics; In the processing industry, we must do a variety of optimization, but the processing technology can not significantly improve the product qualification rate of alumina ceramic manipulator.

3. Alumina ceramics itself has high requirements for grinding processing accuracy, so in surface processing, tool wear leads to dimensional accuracy and surface finish reduction, if the ceramic workpiece has high requirements for surface finish, it needs further polishing processing, which also increases the cost of processing.

4. Alumina ceramic grinding processing, easy to produce a large number of hard fine ceramic powder, the powder is easy to invade the spindle and other accessories of the machine tool, resulting in machine tool production failure, serious damage to the machine tool. In order to solve this problem, Semicera Energy specially introduced a special ceramic engraving and milling machine, which basically solved this problem fundamentally, and the processing accuracy of the workpiece has also been greatly improved. Semicera Energy has obvious advantages in precision machining alumina ceramic manipulator, not only has a professional technical personnel team, There are also special complete sets of processing equipment.

Post time: Sep-04-2023