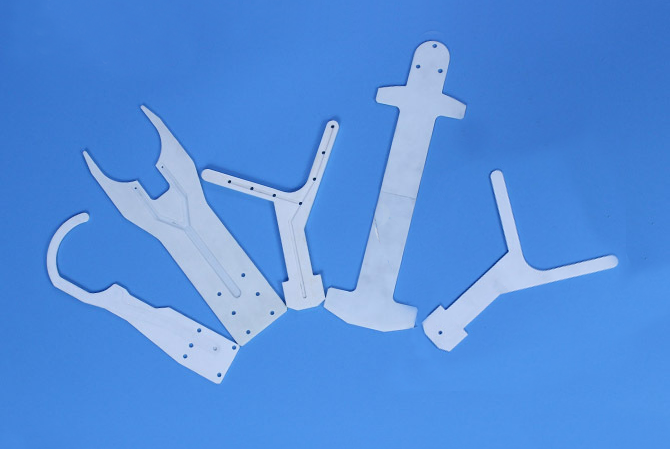

Alumina ceramic arm is also known as ceramic manipulator, ceramic arm. The end effector, etc., the alumina ceramic arm forms the back end of the robot arm and is used to move and operate the semiconductor chip in different positions. It's basically the arm of a robot. Using the characteristics of alumina ceramics, the thermal stability and dimensional stability of the ceramic arm are important, and will not pollute the room with chemical pollutants.

Ceramic arms are used in the semiconductor industry for handling and handling in the production process. In a vacuum environment, it can handle and process wafers.

In robotics, an end effector is a device or tool that is attached to the end of a robotic arm where the hand will be. The end-effector is the part of the robot that interacts with the environment. The structure of the end-effector and the nature of the programming and hardware that drives it depend on the tasks that the robot will perform. If a robot needs to pick something up, a robotic hand called a gripper is the most effective end-effector.

Alumina ceramics have excellent thermal stability, mechanical and wear resistance, and the choice of ceramic materials as high-quality components is clear. The wear resistance and long service life of specialty ceramics make them ideal for mechanical equipment and thermal stability as well as harsh environmental conditions.

Post time: Sep-04-2023