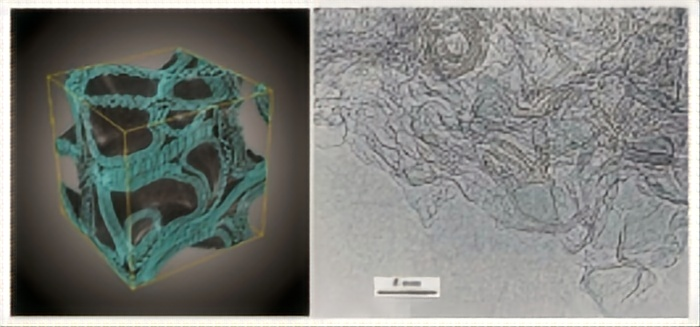

I. Introduction to glassy carbon structure

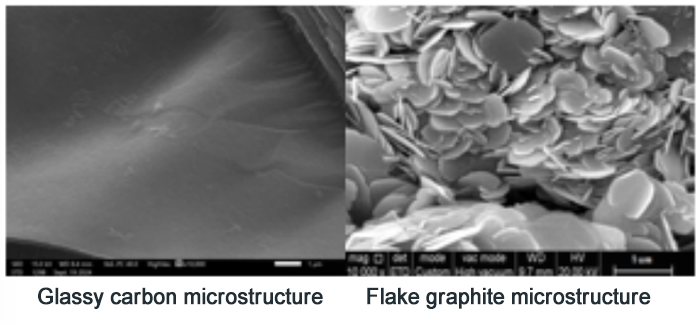

Characteristics:

(1) The surface of glassy carbon is smooth and has a glassy structure;

(2) Glassy carbon has high hardness and low dust generation;

(3) Glassy carbon has a large ID/IG value and a very low degree of graphitization, and its thermal insulation performance is better;

(4) Glassy carbon is a difficult-to-graphitize carbon with good high temperature resistance and strong stability at high temperatures;

(5) Glassy carbon has a small reaction surface area and excellent chemical corrosion resistance, and is more resistant to erosion by oxygen, silicon, etc.

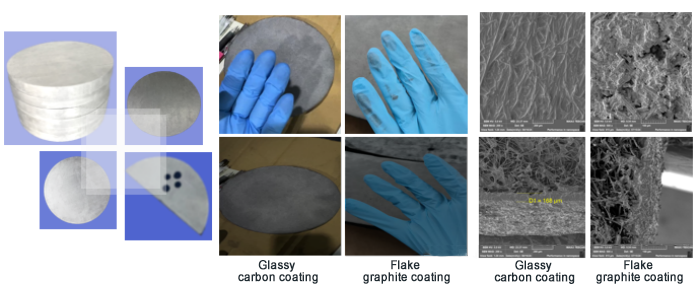

II. Introduction to glassy carbon coating

The surface pores of flake graphite coating are distributed and the structure is loose, while the structure of glassy carbon coating is tight and does not fall off!

1. Anti-oxidation performance of glassy carbon coating

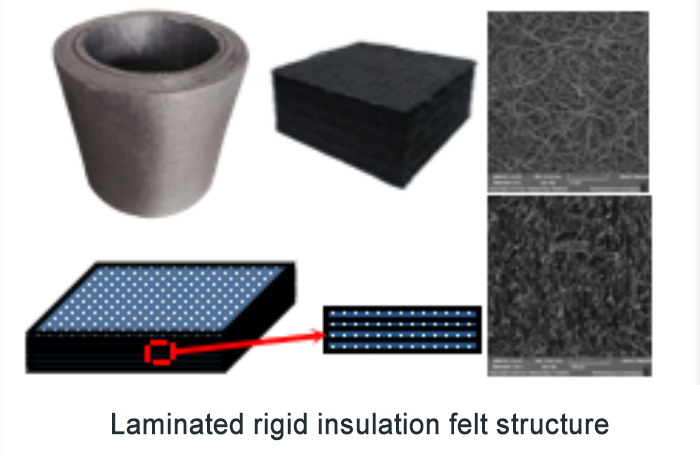

(1) Laminated hard felt

Glassy carbon coating effectively improves the anti-oxidation performance of hard felt;

(2)Short fiber hard felt

The overall felt has a high porosity and provides oxygen channels; the flake graphite coating has a loose structure, fewer oxygen channels, and improved anti-oxidation performance; the coated glassy carbon coating has a dense structure, fewer oxygen channels, and the best anti-oxidation performance.

2. High-temperature stability of glassy carbon coating against ablation

The porous structure of plain felt can attenuate heat (heat convection heat dissipation); graphite paper is prone to blistering when ablated; the ablation depth of glassy carbon coating is the shallowest, and its ablation resistance is the strongest; the glassy carbon coating has good thermal insulation performance.

3. Anti-Si erosion performance of glassy carbon coating

Short fiber hard felt is eroded and powdered by Si; flake graphite coating has resistance to Si erosion in the short term; glassy carbon coating has the best anti-erosion performance.

The main reason for Si erosion is that Si gasification directly erodes the surface of the hard felt, resulting in powderization; while the carbon structure of the glassy carbon coating is more stable and has better anti-erosion performance.

Summary

The glassy carbon coating system is not only used on thermal insulation materials, but is also expected to be directly used on the surface of graphite parts and C/C parts, effectively improving the comprehensive service performance of the material.

Post time: Oct-29-2024