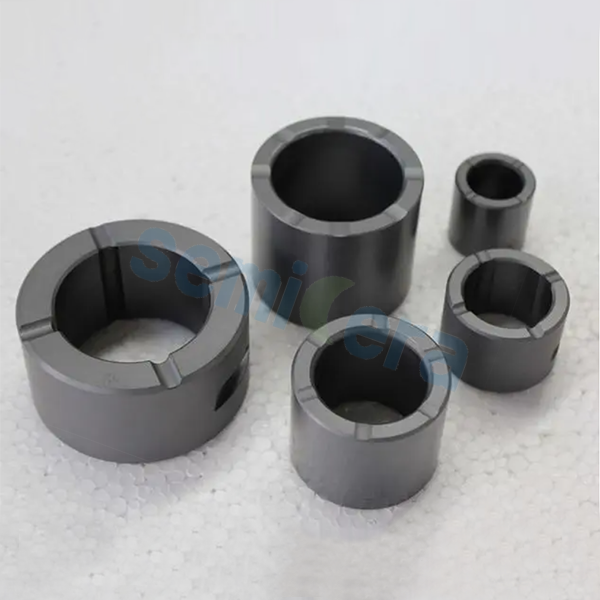

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for New Delivery for High hardness Sisic bushing liner / lining tube / grinding barrel, Our enterprise has already build a experienced, creative and responsible group to create consumers while using the multi-win principle.

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for China Reaction Bonded Silicon Carbide Ceramic and Wear Resistant, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, be sure to contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Description

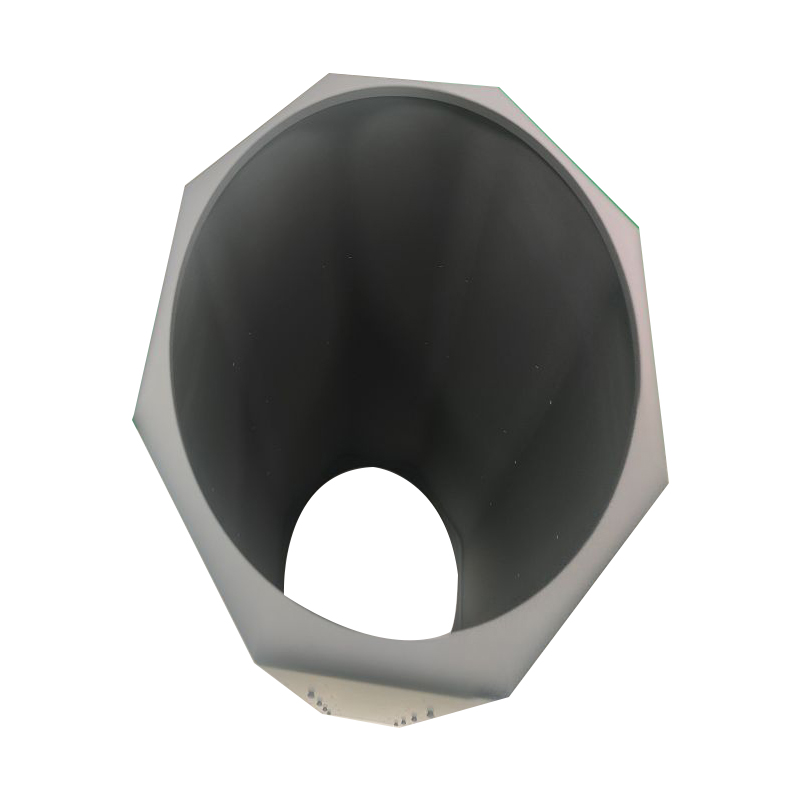

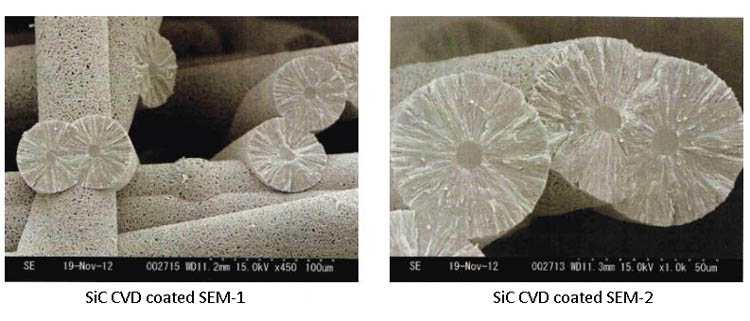

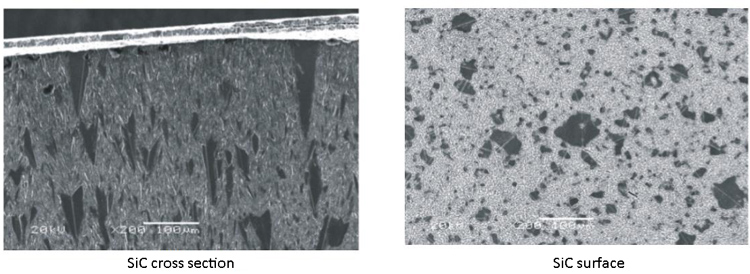

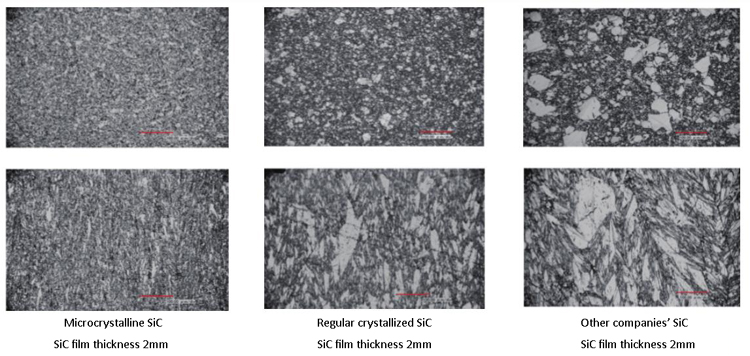

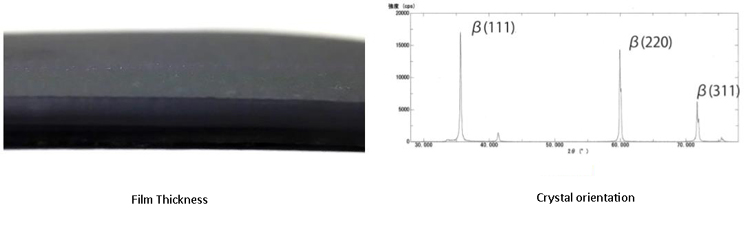

Our company provides SiC coating process services on the surface of graphite, ceramics and other materials by CVD method, so that special gases containing carbon and silicon can react at high temperature to obtain high-purity Sic molecules, which can be deposited on the surface of coated materials to form a SiC protective layer for LPE barrel type hy pnotic.

Main Features

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity : made by chemical vapor deposition under high temperature chlorination condition.

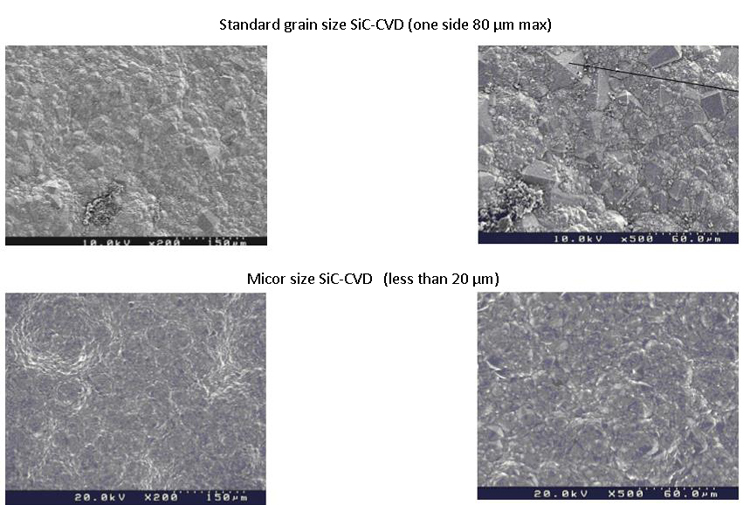

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coating

| SiC-CVD Properties | ||

| Crystal Structure | FCC β phase | |

| Density | g/cm ³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Grain Size | μm | 2~10 |

| Chemical Purity | % | 99.99995 |

| Heat Capacity | J·kg-1 ·K-1 | 640 |

| Sublimation Temperature | ℃ | 2700 |

| Felexural Strength | MPa (RT 4-point) | 415 |

| Young’ s Modulus | Gpa (4pt bend, 1300℃) | 430 |

| Thermal Expansion (C.T.E) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |

Company Profile

WeiTai Energy Technology Co., Ltd. is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

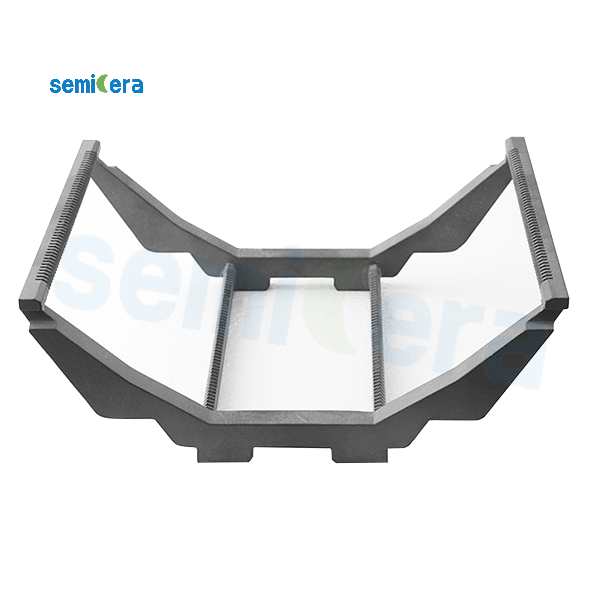

Our main products including: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat(Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, as well as the CVD SiC coating and TaC coating. The products mainly used in the semiconductor and photovoltaic industries, such as equipment for crystal growth, epitaxy, etching, packaging, coating and diffusion furnaces,etc.

Our company has the complete production equipment such as molding, sintering, processing , coating equipment, etc., which can complete all the necessary links of product production and have higher controllability of product quality; The optimal production plan can be selected according to the needs of the product, resulting in lower cost and providing customers with more competitive products; We can flexibly and efficiently schedule production based on order delivery requirements and in conjunction with online order management systems, providing customers with faster and more guaranteed delivery time.

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for New Delivery for High hardness Sisic bushing liner / lining tube / grinding barrel, Our enterprise has already build a experienced, creative and responsible group to create consumers while using the multi-win principle.

New Delivery for China Reaction Bonded Silicon Carbide Ceramic and Wear Resistant, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, be sure to contact us. And It is our great pleasure if you like to have a personally meeting in our office.

-

Good Quality Sell Graphite Sagger Crucible Boat

-

Factory Promotional Soft Felt for Heat Thermal ...

-

Factory Price For Siliconized Silicon Carbide T...

-

Well-designed Alumina Ceramic Insulation Bushing

-

Factory Price China Graphite Products Factory P...

-

High reputation Three-turn silicon carbide spir...