“Based on domestic market and expand abroad business” is our progress strategy for Manufacturer for Refractory Material Ceramic Refractory Sisic Rbsic Silicon Carbide Nozzle Burner Nozzle, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

“Based on domestic market and expand abroad business” is our progress strategy for China Silicon Carbide Brick and Refractory Brick, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you’ve got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We’re confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We’re seeking forward for your inquiries.

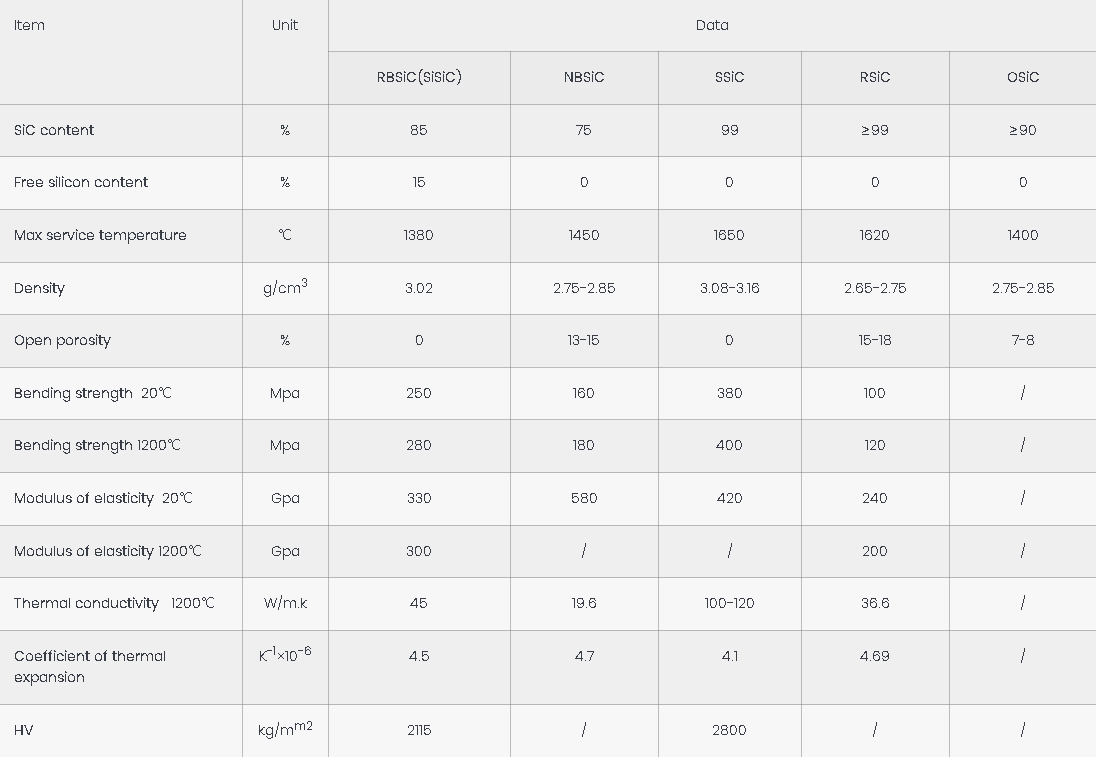

Silicon carbide is a new type of ceramics with high cost performance and excellent material properties. Due to features like high strength and hardness, high temperature resistance, great thermal conductivity and chemical corrosion resistance, Silicon Carbide can almost withstand all chemical medium. Therefore, SiC are widely used in oil mining, chemical, machinery and airspace, even nuclear energy and the military have their special demands on SIC. Some normal application we can offer are seal rings for pump, valve and protective armor etc.

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

![]()

Applications:

-Wear-resistant Field: bushing, plate, sandblasting nozzle,cyclone lining, grinding barrel,etc…

-High Temperature Field: siC Slab, Quenching Furnace Tube,Radiant Tube,crucible,Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat,Kiln car Structure,Setter,etc.

-Military Bulletproof Field

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck,sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway,etc.

-Silicon Carbide Seal Field: all kinds of sealing ring, bearing, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller,etc.

-Lithium Battery Field

![]()

Technical Parameters

All we do is always associated with our tenet ” Customer first, Trust first, devoting on the food packaging and environmental protection for High quality Customized Heat Shock Resistance Silicon Carbide Ssic Ceramic Sand Blasting Nozzle, “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

High quality China Silicon Carbide Ceramic Spray Nozzle and Silicon Carbide Ceramic Burner Nozzles, During in 11 years, We have now participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

-

New Style Wholesale Sic Cantilever Paddles Sili...

-

Rapid Delivery for China Supplier Silicon Carbi...

-

Hot sale Factory High Temperature Resistant Cus...

-

Special Design for Hot Sale Factory Price Refra...

-

Factory Cheap Hot Alumina Ceramic Wear Resistan...

-

Discount wholesale New Type High Temperature Re...