Description

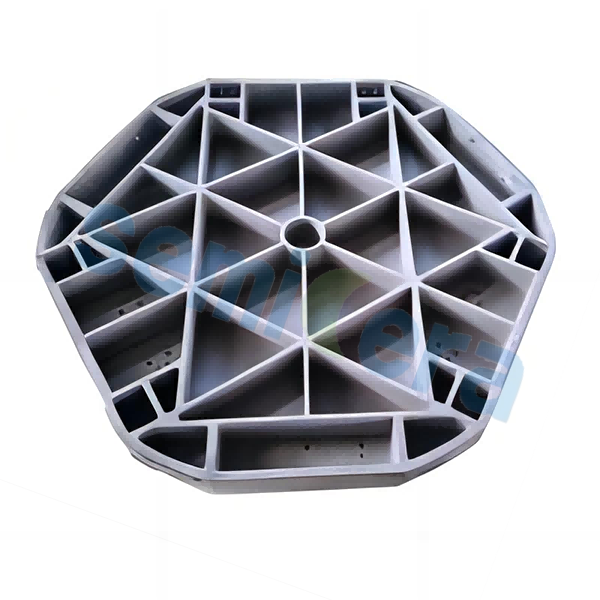

Silicon carbide grinding drum adopts isostatic pressing molding process, density 3.09g/cm3, maximum φ950mm, Vickers hardness 2550HV.

Application of Silicon Carbide ceramic grinding drum in heating element

Silicon carbide ceramic grinding barrel has become the raw material of cathode material for lithium battery because of its important conductive property. SiC heating element is an important product of SiC material and has a broad market prospect.

Silicon carbide grinding barrel advantage

(1) High mechanical strength, as good as

High mechanical strength can effectively prevent material deformation, which is very important. Silicon carbide has higher mechanical strength than corundum. For example, the compressive strength of silicon carbide is 224MPa, while that of corundum is only 75.7MPa. The bending strength of silicon carbide is 15.5MPa, and that of corundum is 8.72MPa.

(2) High hardness and wear resistance

Silicon carbide hardness is quite high, according to the Mohs notch hardness between 9.2 ~ 9.6, second only to diamond and boron carbide, higher than corundum, so in the common grinding and shaking among the best. Compared with metal steel material, it is not only high hardness, but also in the non-lubricating state of friction coefficient is small, relatively small friction, surface roughness is small, wear resistance is good. In addition to the external material has a strong impact resistance, improve the surface bearing capacity.

(3) Low density

The density of silicon carbide is lower than that of metal, so the equipment is lighter.

Company

Wei Tai Energy Technology Co., Ltd.(Miami Advanced Material Technology Co., Ltd) is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

Our main products including: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat(Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, as well as the CVD SiC coating and TaC coating. The products mainly used in the semiconductor and photovoltaic industries, such as equipment for crystal growth, epitaxy, etching, packaging, coating and diffusion furnaces,etc.

Our company has the complete production equipment such as molding, sintering, processing , coating equipment, etc., which can complete all the necessary links of product production and have higher controllability of product quality; The optimal production plan can be selected according to the needs of the product, resulting in lower cost and providing customers with more competitive products; We can flexibly and efficiently schedule production based on order delivery requirements and in conjunction with online order management systems, providing customers with faster and more guaranteed delivery time.