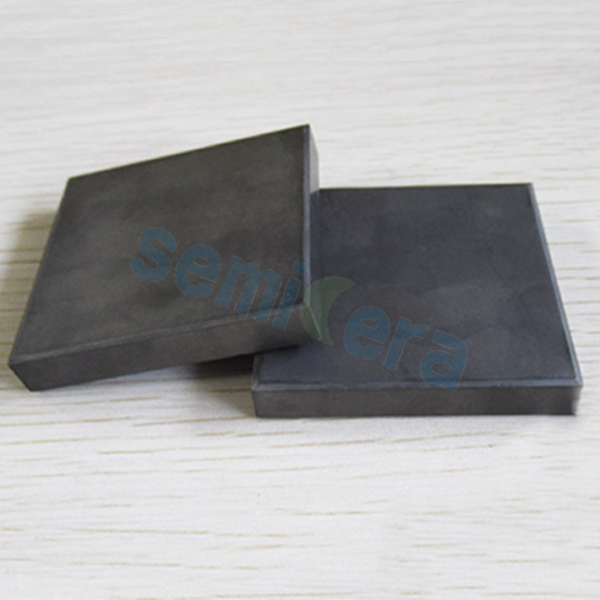

SEMICERA isostatic PECVD graphite boat is a high-purity, high-density graphite product designed for wafer support in the PECVD (plasma enhanced chemical vapor deposition) process. SEMICERA uses advanced isostatic pressing technology to ensure that the graphite boat has excellent high temperature resistance, corrosion resistance, dimensional stability and good thermal conductivity, which is an indispensable consumable in the semiconductor manufacturing process.

SEMICERA isostatic PECVD graphite boat has the following advantages:

▪ High purity: The graphite material is of high purity and low impurity content to avoid contamination of the wafer surface.

▪ High density: High density, high mechanical strength, can withstand high temperature and high vacuum environment.

▪ Good dimensional stability: Small dimensional change at high temperature to ensure process stability.

▪ Excellent thermal conductivity: Effectively transfer heat to prevent wafer overheating.

▪ Strong corrosion resistance: Able to resist erosion by various corrosive gases and plasma.

|

Performance parameter |

semicera | SGL R6510 | Performance parameter |

| Bulk density (g/cm3) | 1.91 | 1.83 | 1.85 |

| Bending strength (MPa) | 63 | 60 | 49 |

| Compressive strength (MPa) | 135 | 130 | 103 |

| Shore Hardness (HS) | 70 | 64 | 60 |

| Coefficient of thermal expansion(10-6/K) | 85 | 105 | 130 |

| Coefficient of thermal expansion(10-6/K) | 5.85 | 4.2 | 5.0 |

| Resistivity (μΩm) | 11-13 | 13 | 10 |

Advantages of choosing us:

▪ Material selection: High-purity graphite materials are used to ensure product quality.

▪ Processing technology: Isostatic pressing is used to ensure product density and uniformity.

▪ Size customization: Graphite boats of different sizes and shapes can be customized according to customer needs.

▪ Surface treatment: A variety of surface treatment methods are provided, such as coating silicon carbide, boron nitride, etc., to meet different process requirements.

-

China Supplier Rigid Carbon Graphite Felt for T...

-

Reasonable price Soft Felt for Heat Thermal Ins...

-

Best Price on High Temperature/Silicon Carbide ...

-

Discount Price Carbon Fiber C/C Composites Soft...

-

China wholesale High Purity High Temperature an...

-

PriceList for Reaction bonded silicon carbide S...