We follow our enterprise spirit of “Quality, Efficiency, Innovation and Integrity”. We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Hot Selling for Customizable Sic Paddles with Diffusion Coating Furnace, At our firm with top quality to start with as our motto, we manufacture products that are entirely made in Japan, from materials procurement to processing. This enables them to get used with confident peace of mind.

We follow our enterprise spirit of “Quality, Efficiency, Innovation and Integrity”. We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for China Paddle and Sic Paddles, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

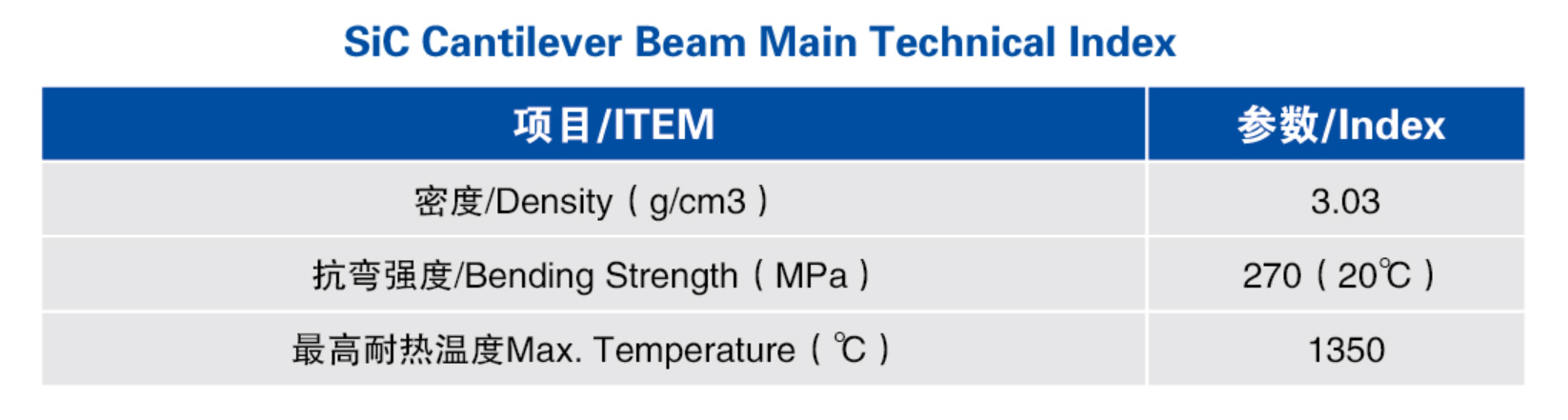

Application of SiC Cantilever Beam

SiC Cantilever paddle is being used in the diffusion coating furnace of the photovoltaic industry for coating monocrystalline and polycrystalline silicon wafers. Its characteristic enables it to withstand high temperature and corrosion, giving it a long life span.

The SiC Cantilever paddle delivers SiC boats /quartz boats which carry silicon wafers into the high temperature diffusion coating furnace tube.

The length of our SiC Cantilever paddle ranges from 1,500 to 3,500 mm. SiC Cantilever paddle’s dimension can be tailor made according to customer’s specification.

Semicera Energy Technology Co., Ltd is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process grouting molding process and vacuum extrusion molding process. Our company uses 6 silicon carbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can also provide you with silicon carbide ceramic sintered products, but also can provide silicon carbide ceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.

We follow our enterprise spirit of “Quality, Efficiency, Innovation and Integrity”. We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Hot Selling for Customizable Sic Paddles with Diffusion Coating Furnace, At our firm with top quality to start with as our motto, we manufacture products that are entirely made in Japan, from materials procurement to processing. This enables them to get used with confident peace of mind.

Hot Selling for China Paddle and Sic Paddles, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

-

Good Quality Long Service Life High Hardness Cu...

-

Cheapest Factory Silicon Carbide Graphite Cruci...

-

Cheapest Price China Factory Dumbbell/Spiral Si...

-

Top Suppliers High Temperature Resistance Recry...

-

ODM Supplier Easy Installation Sic Heating Elem...

-

IOS Certificate Customizable Reaction Sintered ...