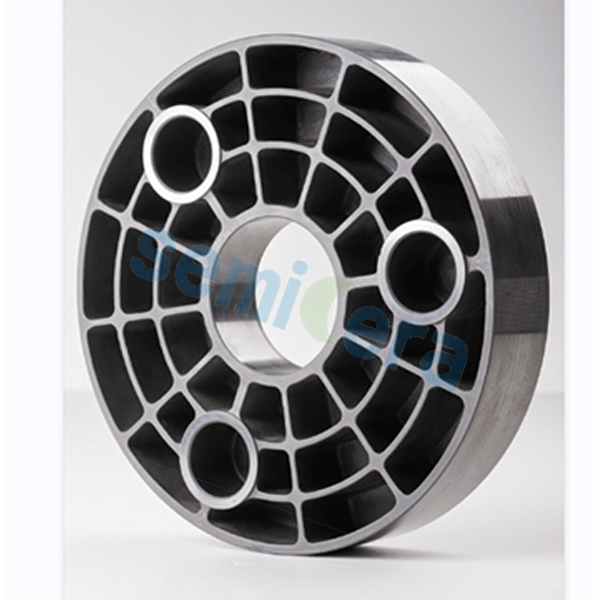

Silicon carbide is a new type of ceramics with high cost performance and excellent material properties. Due to features like high strength and hardness, high temperature resistance, great thermal conductivity and chemical corrosion resistance, Silicon Carbide can almost withstand all chemical medium. Therefore, SiC are widely used in oil mining, chemical, machinery and airspace, even nuclear energy and the military have their special demands on SIC. Some normal application we can offer are seal rings for pump, valve and protective armor etc.

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

Characteristics and advantages

1.Precise dimensions and thermal stability

2.High specific stiffness and excellent thermal uniformity, long-term use is not easy to bend deformation;

3.It has a smooth surface and good wear resistance, thus safely handling the chip without particle contamination.

4.Silicon carbide resistivity in 106-108Ω, non-magnetic, in line with anti-ESD specification requirements; It can prevent the accumulation of static electricity on the surface of the chip

5.Good thermal conductivity, low expansion coefficient.