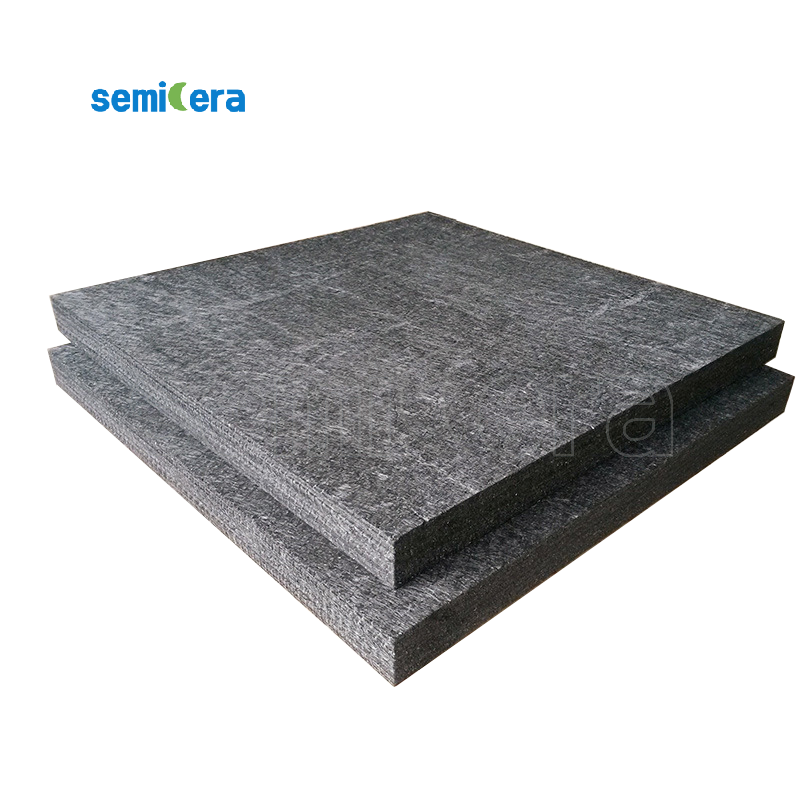

Semicera introduces high-quality semiconductor silicon carbide cantilever paddles, designed to meet the stringent demands of modern semiconductor manufacturing.

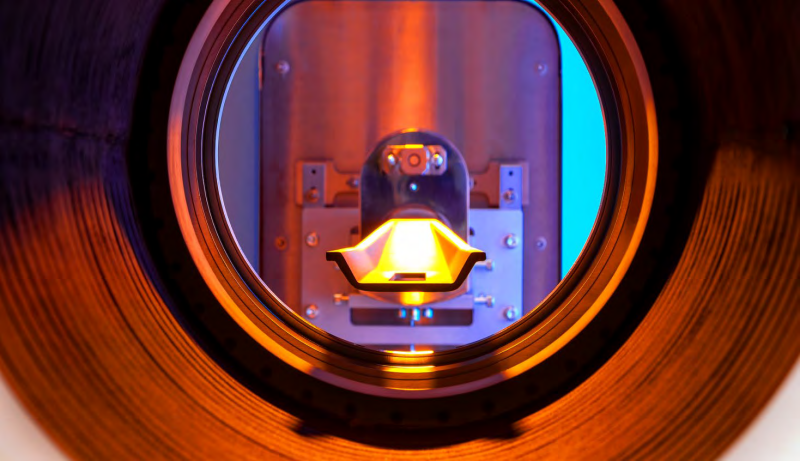

The silicon carbide paddle features an advanced design that minimizes thermal expansion and warping, making it highly reliable in extreme conditions. Its robust construction offers enhanced durability, reducing the risk of breakage or wear, which is critical in maintaining high yields and consistent production quality. The wafer boat design also integrates seamlessly with standard semiconductor processing equipment, ensuring compatibility and ease of use.

One of the standout features of the Semicera SiC paddle is its chemical resistance, which allows it to perform exceptionally well in environments exposed to corrosive gases and chemicals. Semicera's focus on customization allows for tailored solutions.

|

Physical properties of Recrystallized Silicon Carbide |

|

|

Property |

Typical Value |

|

Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

SiC content |

> 99.96% |

|

Free Si content |

< 0.1% |

|

Bulk density |

2.60-2.70 g/cm3 |

|

Apparent porosity |

< 16% |

|

Compression strength |

> 600 MPa |

|

Cold bending strength |

80-90 MPa (20°C) |

|

Hot bending strength |

90-100 MPa (1400°C) |

|

Thermal expansion @1500°C |

4.70 10-6/°C |

|

Thermal conductivity @1200°C |

23 W/m•K |

|

Elastic modulus |

240 GPa |

|

Thermal shock resistance |

Extremely good |