Silicon Carbide (SiC) Powder Overview

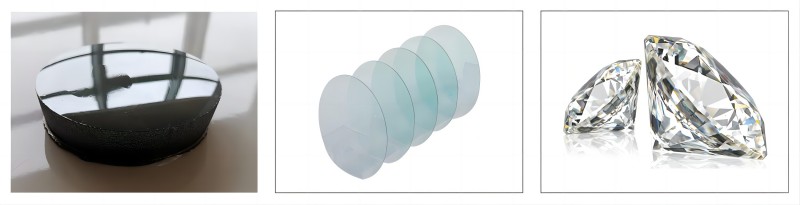

Silicon carbide (SiC), also known as carborundum or emery, is one of the most widely used and economical materials. SiC is available in two forms: black silicon carbide and green silicon carbide.

Production Process

SiC is produced by melting quartz sand, petroleum coke, or coal tar, and wood chips at high temperatures in a resistance furnace. Green silicon carbide is specifically made by melting high-quality silicon dioxide and petroleum coke, with salt added as an additive.

Properties and Applications

-Hardness: Falls between corundum and diamond.

-Mechanical Strength: Higher than corundum, brittle, and sharp.

-Conductivity: Possesses certain electrical and thermal conductivity.

Due to these properties, SiC is ideal for applications requiring durability and thermal management. It is extensively used in industries such as abrasives, refractories, and semiconductors.

Features of Silicon Carbide

1. Low Thermal Expansion: Minimizes changes in size with temperature fluctuations.

2. High Thermal Conductivity: Efficiently transfers heat.

3. Thermal Stress Resistance: Reduces the likelihood of thermal stress.

4. Excellent Thermal Shock Resistance: Withstands rapid temperature changes.

5. Corrosion Resistance: Durable against chemical damage.

6. Extreme Temperature Tolerance: Performs well in both extremely cold and hot environments.

7. High-Temperature Creep Resistance: Maintains stability and strength at high temperatures.

Semicera can customize 4N-6N silicon carbide powder according to your needs, welcome to inquire.

|

CHEMICAL CONTENT |

|

|

SiC |

98% min |

|

SiO2 |

1% max |

|

H2O3 |

0.5% max |

|

Fe2O3 |

0.4% max |

|

F.C |

0.4% max |

|

Magnetic Material |

0.02% max |

|

PHYSICAL PROPERTIES |

|

|

Moh's Hardness |

9.2 |

|

Melting Point |

2300℃ |

|

Working Temperature |

1900℃ |

|

Specific Gravity |

3.2-3.45 g/cm3 |

|

Bulk Density |

1.2-1.6 g/cm3 |

|

Color |

Black |

|

Elasticity Modulus |

58-65x106psi |

|

Coefficient of Thermal Expansion |

3.9-4.5 x10-6/℃ |

|

Thermal Conductivity |

71-130 W/m.K |

|

Grain Size |

|

|

0-1mm,1-3 mm, 3-5mm, 5-8mm,6/10, 10/18,200-0mesh,325mesh,320mesh,400mesh,600mesh,800mesh,1000mesh, |

|