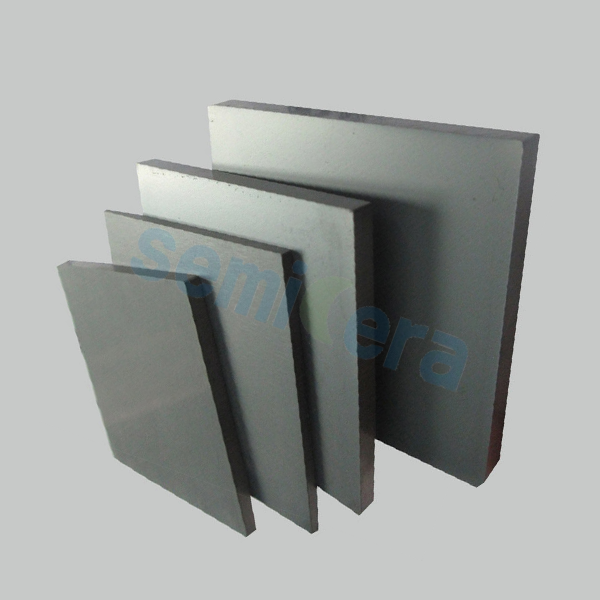

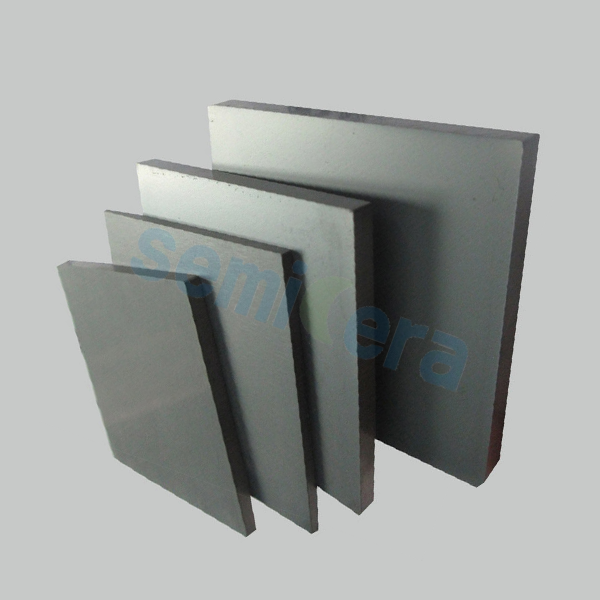

Description

Application of Silicon Carbide ceramic grinding drum in heating element

Silicon carbide ceramic grinding barrel has become the raw material of cathode material for lithium battery because of its important conductive property. SiC heating element is an important product of SiC material and has a broad market prospect.

![]()

![]()

Silicon carbide grinding barrel advantage

(1) High mechanical strength, as good as

High mechanical strength can effectively prevent material deformation, which is very important. Silicon carbide has higher mechanical strength than corundum. For example, the compressive strength of silicon carbide is 224MPa, while that of corundum is only 75.7MPa. The bending strength of silicon carbide is 15.5MPa, and that of corundum is 8.72MPa.

(2) High temperature resistance, small coefficient of thermal expansion

Silicon carbide is made at high temperatures. In some high temperature environment, the material is required to have a certain processing strength, and meet the processing accuracy, and silicon carbide ceramics can achieve these two points. The highest use temperature of silicon carbide is about 800℃, and the bearing temperature of steel is only 250℃. By rough calculation, the average thermal expansion coefficient of SIC is 4.4×10-6/ C in the range of 25~1400℃. The thermal expansion coefficient of SIC is much smaller than that of other abrasives and high temperature materials. For example, the coefficient of thermal expansion of corundum can be as high as (7~8)× 10-6/℃.

(3) Corrosion resistance

Silicon carbide because of its melting point (decomposition temperature), chemical inertia and thermal shock resistance is high, can be used for a variety of silicon carbide ceramic products, such as ceramic products furnace grinding tools, ceiling plate and sagger, zinc smelting industrial vertical cylinder distillation furnace with silicon carbide brick, aluminum electrolytic cell lining, crucible, small furnace material.

Corrosion resistance application

1, Sliding parts (mechanical seal, chemical pump bearing, shaft)

2, Crusher accessories (classifier, air mill, sand mill)

3.Semiconductor manufacturing equipment parts (XY platform, MOCVD tray, focusing ring, wafer chuck)

4. Parts of molding machine (parts of camera lens molding machine)

5. Heat resistant parts (burner nozzle, high temperature testing machine parts, molten metal crucible)

6. Wear-resistant parts (sand blasting machine nozzle, shot blasting machine polishing machine blade, buried pipeline protection plate, fishing tackle guide ring)

Transport

FAQ

Q: Are you trading company or manufacturer?

A:We are an more than 10 vears factory with iso9001 certificacted

Q:How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock,or 10-15 days if the goods are not in stock, it is according to your quantity.

Q: How can Iget the sample to check your quality?

A: After price confirmation, you can require for samples to check our product's quality. If you just need a blank sample to check the design and quality,we will provide you sample for free as long as you afford the express freight.

Q:What is your terms of payment?

A: We accept payment by Western union,Pavpal,Alibaba,T/TL/Cetc.for bulk order,we do 30% deposit balance before shipment.

if you have another question,pls feel free to contact us as below.

Why you can choose Wei Tai ?

1) we have sufficient stock guarantee.

2) professional packaging ensures product integrity. The product will be delivered to you safely.

3) more logistics channels enable products to be delivered to you.

-

Hot New Products Factory Price Custom Industria...

-

Professional Factory for Ceramic Logo Customize...

-

Professional China Graphite Felt Carbon Graphit...

-

High Quality Refractory Ceramic Rsic Recrystall...

-

Chinese wholesale Sintering Silicon Carbide Cer...

-

Long Service Life SiC Coated Graphite Carrier F...