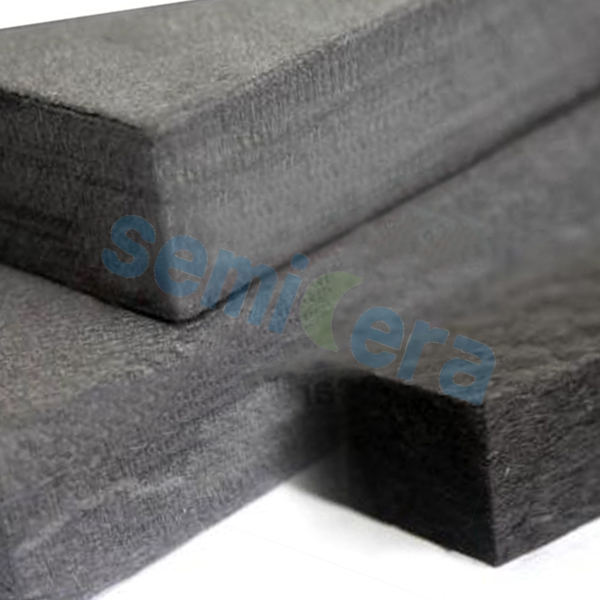

Among material products, CVD-SiC is a growth product, which can be used as fixtures and components of semiconductor production equipment. Silicon carbide is a compound composed of silicon and carbon 1:1, and its hardness is second only to diamond and boron carbide. Weitai is manufactured using the CVD process, a gas containing silicon and carbon. Taking the silicon wafer as an example, the silicon carbide is coated on the surface of the graphite substrate processed into a disc by the CVD method, after cutting the outer edge, the graphite substrate is removed by high temperature oxidation, and then after several subsequent processing, the silicon wafer is completed. In high-end industries such as energy, silicon carbide, a high-purity material, has received more and more attention.

Characteristics of silicon carbide components

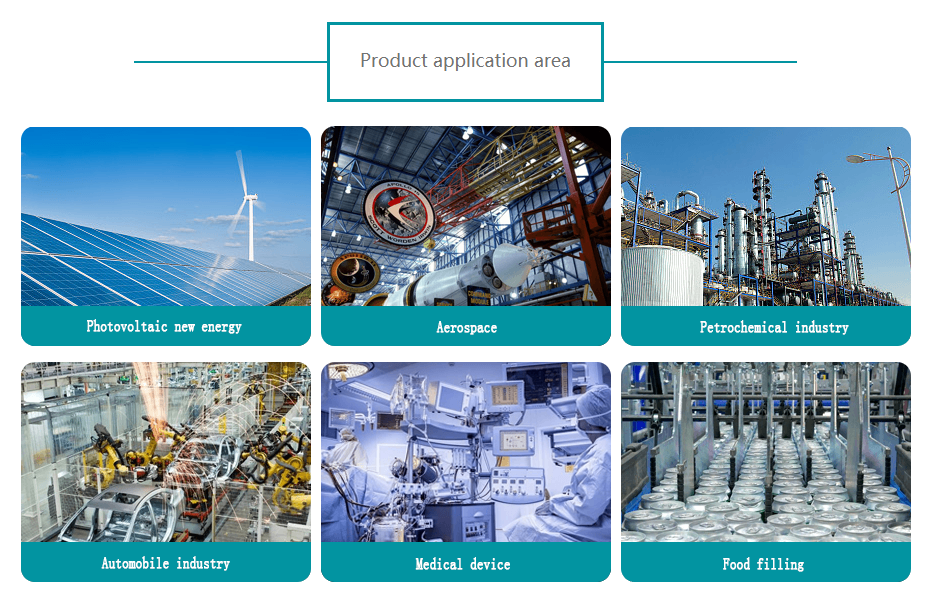

Weitai SiC component products have high oxidation resistance, chemical stability and heat resistance, with excellent characteristics of stability even at 2000 degrees. They are widely used in wafer boats, tubes and simulation wafers that replace silicon wafers required in the manufacturing process of semiconductor materials, and are also widely used in fixture products used at high temperatures. It is widely used in semiconductor production equipment, automotive field, energy field and other fields.

WeiTai Energy Technology Co., Ltd. is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

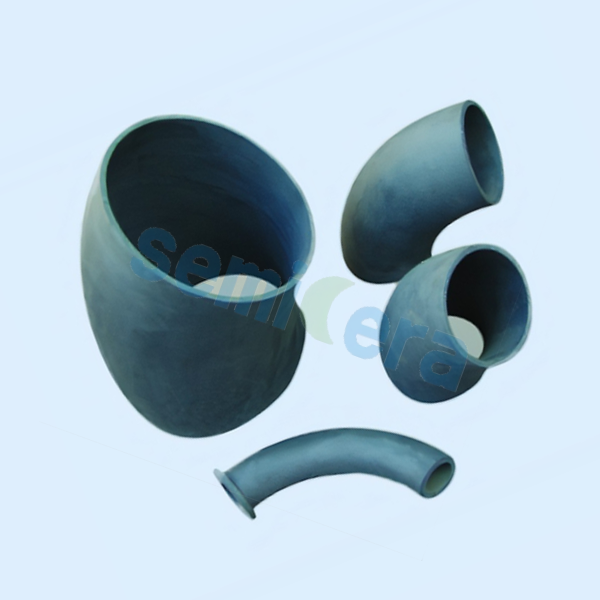

Our main products including: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat(Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, as well as the CVD SiC coating and TaC coating. The products mainly used in the semiconductor and photovoltaic industries, such as equipment for crystal growth, epitaxy, etching, packaging, coating and diffusion furnaces,etc.

Our company has the complete production equipment such as molding, sintering, processing , coating equipment, etc., which can complete all the necessary links of product production and have higher controllability of product quality; The optimal production plan can be selected according to the needs of the product, resulting in lower cost and providing customers with more competitive products; We can flexibly and efficiently schedule production based on order delivery requirements and in conjunction with online order management systems, providing customers with faster and more guaranteed delivery time.

At the same time, our company relies on expert teams such as enterprise technology centers, first-class universities,and research institutions to establish an enterprise innovation and research team with multiple doctors, masters and engineers, laying a solid foundation for long-term development.

Welcome customers from all over the world to visit us and have a technical discussion, We will work together with you to develop and create brilliant prospects.