Graphite three-petal crucible for semiconductor crystal growth: Made of high-purity raw materials and manufactured through precision technology, it has excellent high temperature resistance, corrosion resistance, and thermal conductivity. During high-temperature use, the thermal expansion coefficient is small, and it has a certain resistance to strain against rapid heating and cooling. It has strong corrosion resistance to acid and alkaline solutions and excellent chemical stability.

In semicera's product line, we introduce Isostatic Graphite Components designed for semiconductor crystal growth.

At semicera, we prioritize quality and innovation. Our crucibles are coated with CVD SiC, which significantly increases their durability and lifespan. This cutting-edge coating further enhances their resistance to harsh chemical environments, making them the ultimate choice for semiconductor manufacturing.

To meet the demanding requirements of the semiconductor industry for precision crystal growth, we have used advanced material processes to ensure that the Graphite three-petal crucible performs well in different environments. This product not only carries the semicera brand name, but also reflects our commitment to technological innovation and quality excellence.

The Graphite three-petal crucible is not only designed with ingenuity, but also undergoes strict quality control and testing to ensure that every product meets the highest standards. Whether in laboratory research or industrial applications, our Graphite three-petal crucible can perform stably and reliably to help you achieve a higher level of semiconductor crystal growth.

When you choose the Graphite three-petal crucible from semicera, you not only get excellent performance, but also trust in innovative technology. Experience our products now and experience the endless possibilities brought by excellent quality!

The main products of semicera are fine particle isostatically pressed graphite used in semiconductors. The basic information of the world's most advanced German SGL and Japanese Toyo carbon products is as follows:

| Performance parameter | semicera | SGL R6510 | TOYO IG310 |

|

Bulk density (g/cm3) |

1.91 |

1.83 |

1.85 |

|

Bending strength (MPa) |

8-10 |

60 |

49 |

|

Compressive strength (MPa) |

135 |

130 |

103 |

|

Shore Hardness (HS) |

70 |

64 |

60 |

|

Thermal conductivity (W/m·K) |

85 |

105 |

130 |

|

Coefficient of thermal expansion(10-6/K) |

5.85 |

4.2 |

5.0 |

|

Resistivity (μΩm) |

11-13 |

13 |

10 |

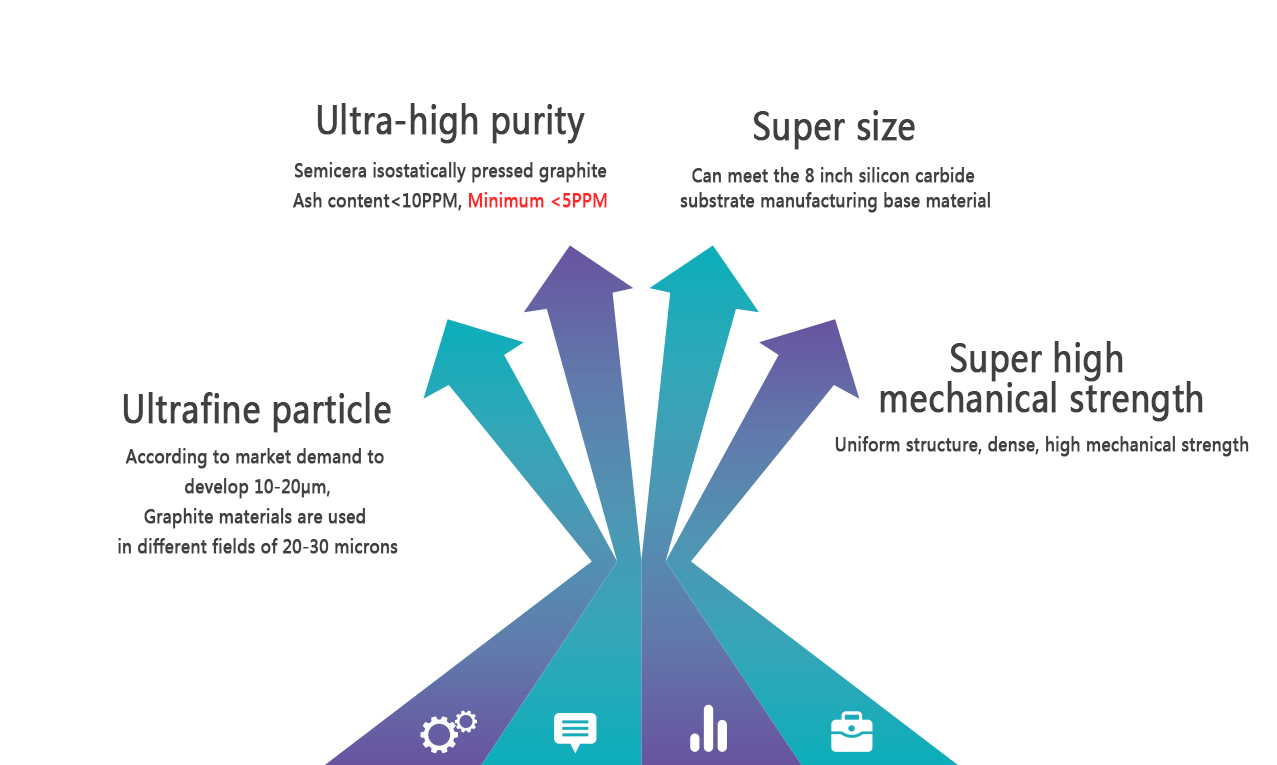

Performance advantage:

1.The structure is fine and dense, and the uniformity is good.

2.Low coefficient of thermal expansion, excellent thermal shock resistance;

3.Isotropy;

4.Strong chemical resistance;

5.Good thermal and electrical conductivity;

6.It has excellent machining properties.

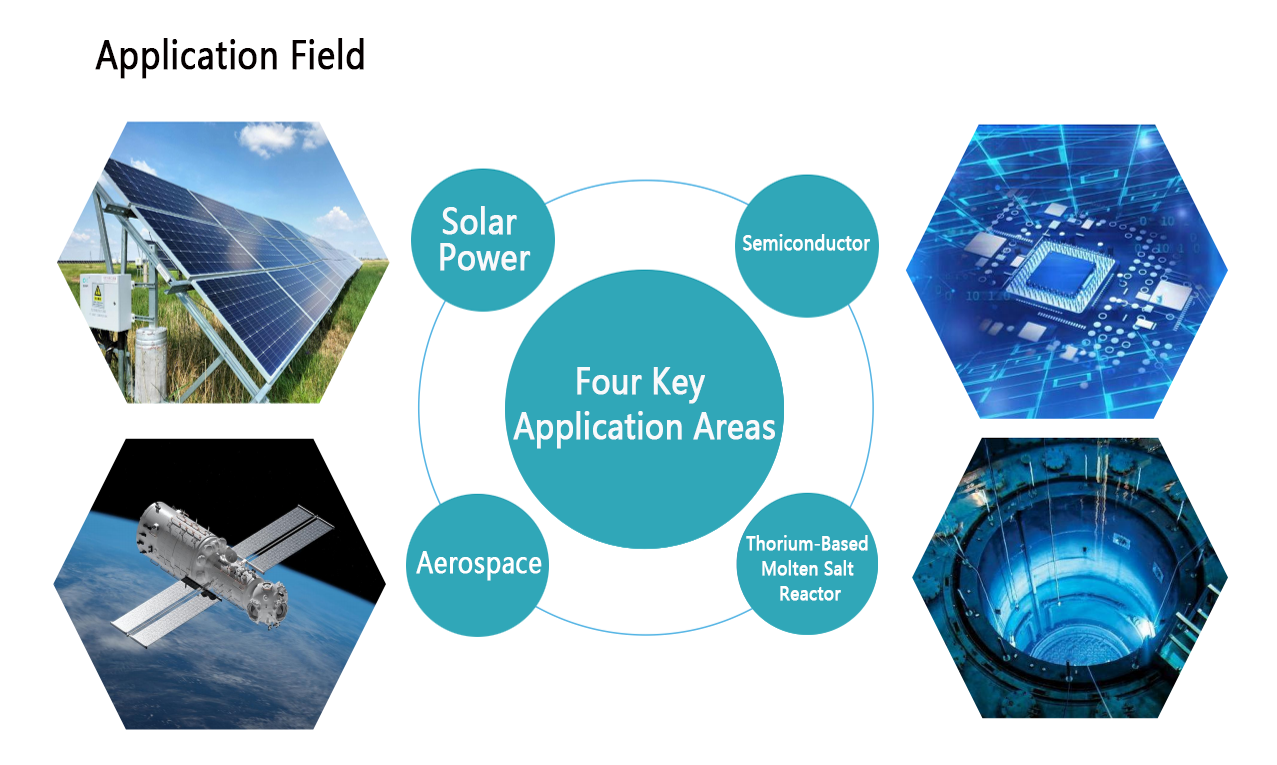

Key basic materials for contemporary industry

1. Semiconductor industry

2. Solar energy industry

3. Aerospace industry

4. The nuclear industry

Semicera isostatic pressed graphite project, has been through mass production to obtain high density, high purity, high strength,Large size graphite products